-

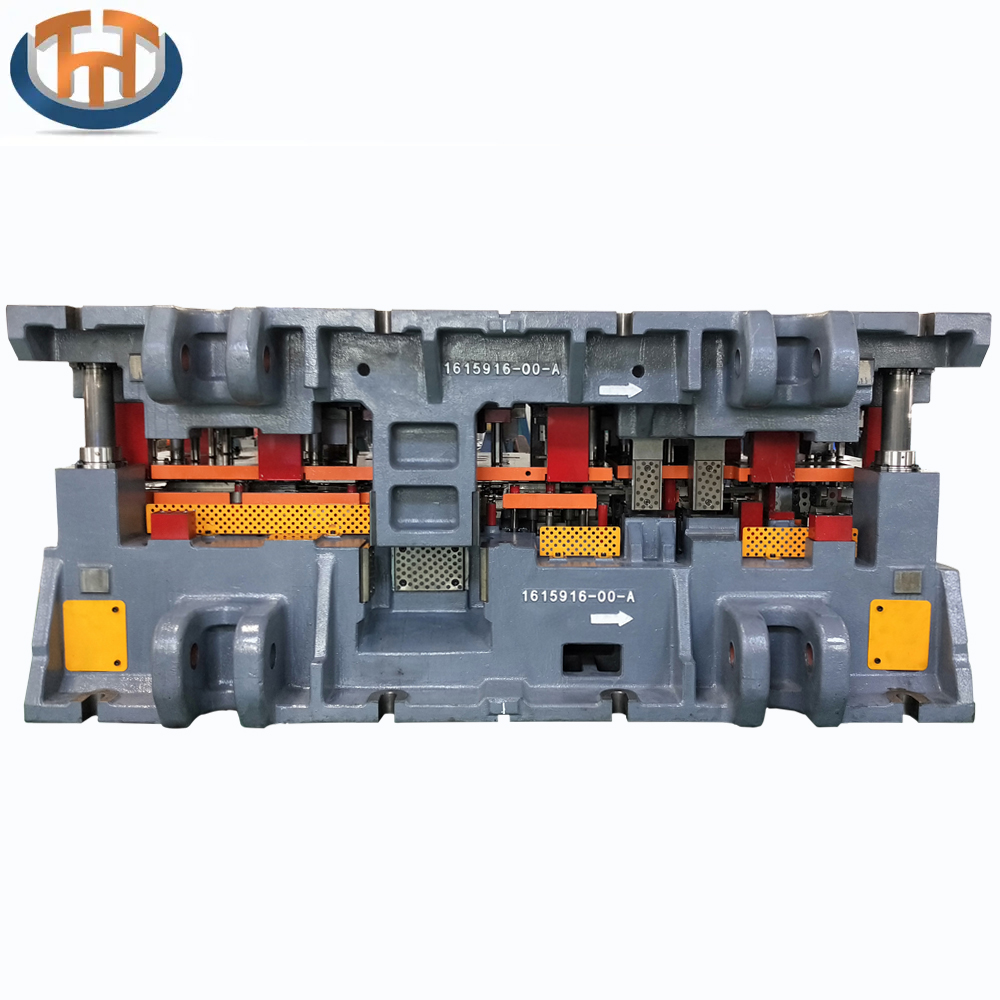

Automotive A-pillar Casting Transfer Metal Stamping Dies and Tools

-

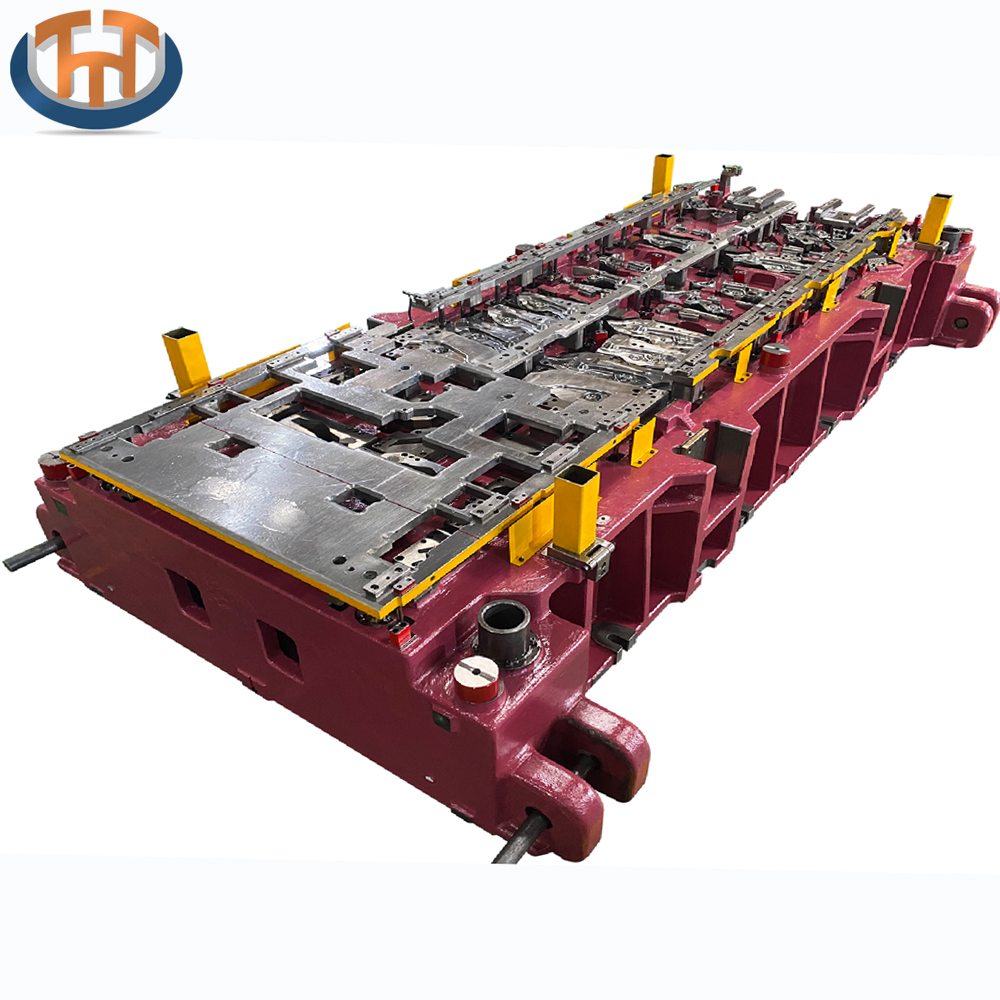

Automotive D Pillar Metal Stamping Dies Design and Manufacturer

-

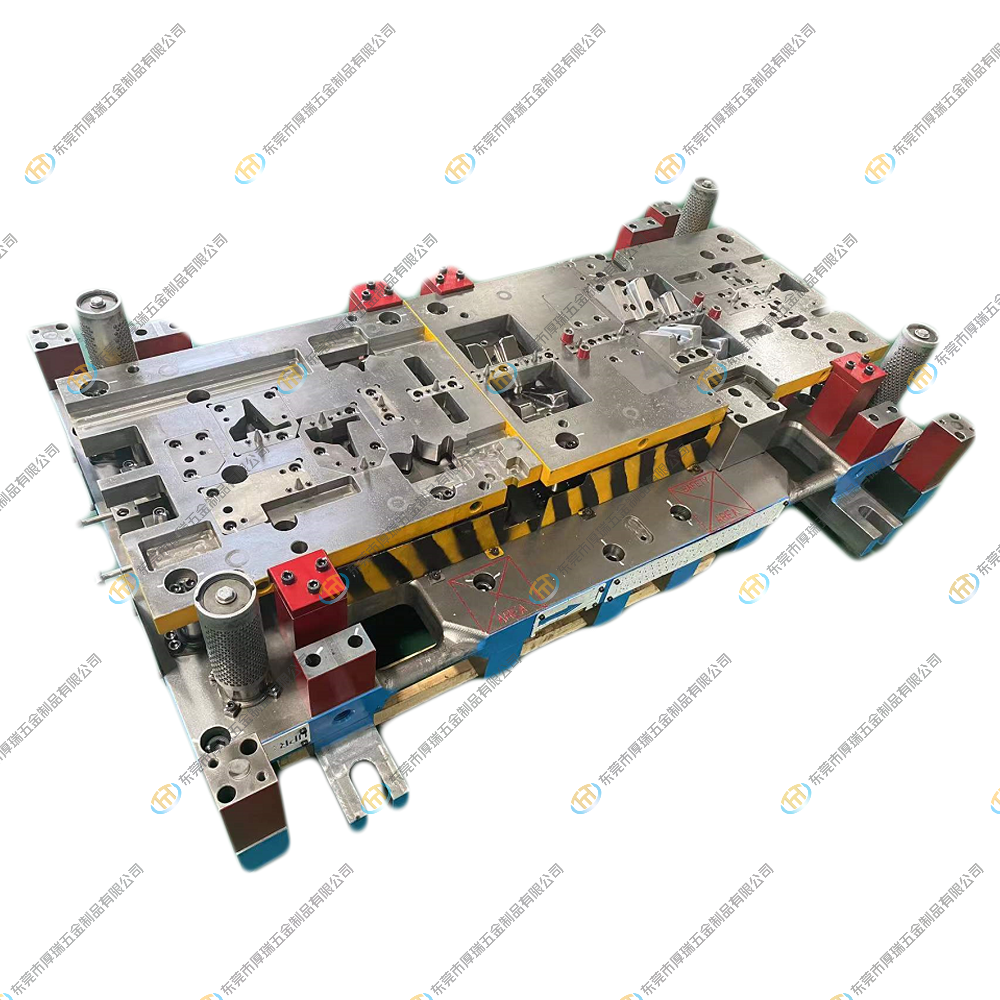

Customize Progressive Steel Stamping Dies and Tools for Automotive ...

-

Manufacture And Design Automotive Sheet Metal Stamping Die

-

Automotive and Vehicle Sheet Metal Parts Stamping Die Manufacturers

-

Automotive Sheet Metal Die And Stamping Manufacturer

-

Automotive Sheet Metal Part and Component Stamping Tools

-

Custom Automotive Metal Parts And Car Components Progressive Die

-

High-quality Automotive Casting progressive die manufacturer and Fa...

-

One Stop Service Metal Tooling Supplier Stamping Mould Stamping Part

-

High Precision Prog tool Sheet Metal Deep Drawing Die Producer

-

Custom Automotive Metal Stamping Dies Punching Machines

-

E-mail

-

.png)

Wechat

Wechat

+86-13902478770

-

.png)

Whatsapp

.png)

.png)