Custom Automotive Metal Stamping Dies Punching Machines

Video

Manufacturing Center

We can build all kinds of different size fixture including large size fixture as we have big CNC Machines:3m and 6m.

With a variety of mechanical equipment such as milling, grinding, wire cutting machines and drilling machines, we can effectively and accurately control the processing process.

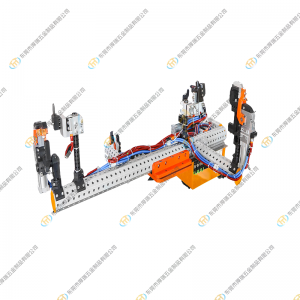

Arc Welding Work Station

Complete the jobs from 3D, 2D design to simulation,manufacturing, final assembly, wiring&piping, robot programming, commission and home-line support.

Introduction

TTM focuses on providing high-quality molds and mold-related services for the automotive industry, and its product range covers a variety of automotive parts, such as body panels, doors, seats, dashboards, etc. The manufacturing process of TTM molds adopts advanced technology and equipment, such as computer-aided design, numerical control machining, 3D printing, etc., which can ensure the precision and quality of molds. In addition, TTM Mold also provides mold repair and improvement services to help customers improve production efficiency and reduce costs.

Quality Management And Control

.png)

.png)