Auto Stamping Parts Welding Fixture Customized Production Process Gage

Video

|

Base Material: |

Al |

Application: |

Stamping Parts |

|

Surface Treatment: |

Oxidation/Paint |

Certificate: |

ISO 9001:2008 |

|

Software: |

Catia, UG, CAD, STP |

Packing: |

Wooden Box |

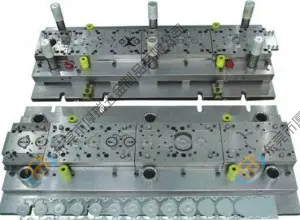

Weld Fixture Of Automotive Part Customized Production Process Gage

Production Specification

All holes that are denoted with a positional location tolerance (true position) of 1.0mm or less shall have a stab pin check for location.

If all hole positions are greater than 1.0, then one hole will be selected for a stab pin check. If multiple pierce stations are used, one hole will be identified out of each station for a stab pin check.

Hole locations which don’t require a stab pin check will require a hole presence pin that is to be a light press fit (easily removed) and a scribe line or machined groove min/max painted yellow. True position diametrical tolerances are always at MMC, unless otherwise specified.

Material

Base Plate and body: Aluminium

Color

Base Plate and Body: Original Color of Metal

The Steel and Aluminum Parts: Original Color of Metal

Our production detail

| Items | ||

| 1 | Base Material | Al |

| 2 | Application | Stamping Parts |

| 3 | Surface treatment | Oxidation/Paint |

| 4 | Processing Precision | 0.15 |

| 5 | Accuracy for Other Profiles | 0.1 |

| 6 | Accuracy for Datum Hole | ±0.05 |

| 7 | Certificate | ISO 9001:2008 |

| 8 | CMM certification | Yes |

| 9 | Software | Catia, UG, CAD, STP |

| 10 | Specification | 960KG |

| 11 | Packing | Wooden Box |

Manufacturing tolerance

1.The Flatness of Base Plate 0.05/1000

2.The Thickness of Base Plate ±0.03mm

3.The Location Datum ±0.02mm

4.The Surface ±0.1mm

5.The Checking Pins and Holes ±0.1mm

Process

CNC Machining(Milling/Turning), Grinding

Electroplating Chromium Treatment

Quality Control

CMM (3D Coordinate Measuring Machine), Vms-2515G 2D Projector, HR-150 A Hardness Tester

Third Party Certification done by ShenZhen Silver Basis Testing Technology Co., Ltd , ISO17025 Certified

Lead time & Packing

35 days after 3D design approved

7 days via express: FedEx

Standard Export Wooden Case

Primary Competitive Advantages

Pursuit Of Quality Excellence

Multiple Products & Services

Efficiency Consciousness-On-Time Delivery

Cost Consciousness-Innovative Design Solutions To Reduce The Cost

Timely Communication With Our Customer

Compliance With Cooperator’s Terms And Conditions

NDA(Non-disclosure Agreement)

Our purpose is that we can only succeed if our customers succeed.

.png)

.png)