Precision Tools in Automotive Manufacturing: Unveiling the Marvels of Stamping

Introduction:

In the dynamic world of automotive manufacturing, the role of precision tools is paramount, and one such indispensable component is automotive stamping tools. These tools play a crucial role in shaping metal sheets into intricate and precise components that form the backbone of modern vehicles. While the automotive industry is no stranger to technological advancements, the artistry behind stamping tools often goes unnoticed. This article explores the intricacies of automotive stamping tools, shedding light on their significance and the innovation driving this critical aspect of production.

The Core Functionality:

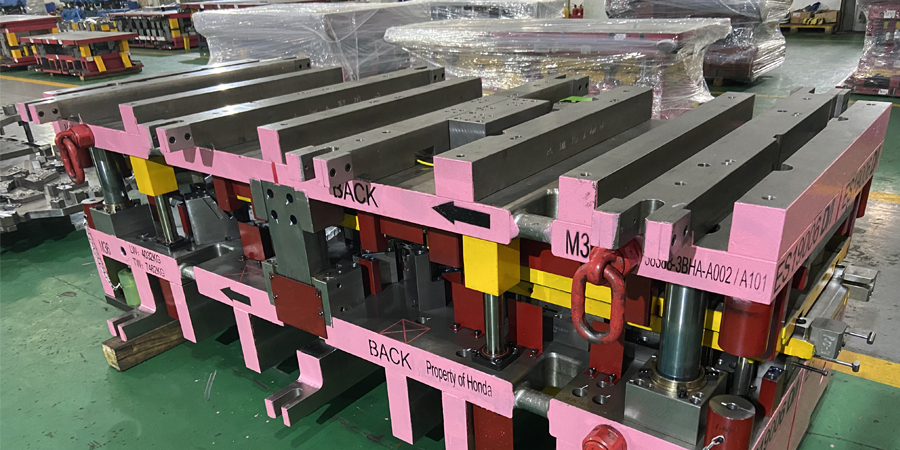

At the heart of automotive stamping lies the process of transforming flat metal sheets into three-dimensional components. Stamping tools employ a combination of dies and presses to exert immense pressure on the metal, shaping it into desired forms. The precision and consistency achieved through this method are unparalleled, making it a preferred choice in the production of vehicle parts such as body panels, chassis components, and intricate details.

Materials and Innovation:

As automakers strive for lightweight yet durable structures, stamping tools have evolved to accommodate a variety of materials. Traditionally associated with steel, modern stamping tools are designed to handle aluminium, advanced high-strength alloys, and even composite materials. This adaptability not only contributes to the weight reduction of vehicles but also enhances fuel efficiency and overall performance.

Furthermore, the integration of advanced technologies like computer-aided design (CAD) and simulation software has revolutionized the design and manufacturing process. Engineers can now create intricate stamping tool designs with unprecedented precision, optimizing material usage and minimizing waste. This technological leap ensures that automotive stamping remains at the forefront of efficiency and sustainability in manufacturing.

Automation and Industry 4.0:

The automotive industry is undergoing a paradigm shift with the advent of Industry 4.0. Automation has become a key player in optimizing production processes, and stamping tools are no exception. Automated stamping lines equipped with robotics and artificial intelligence enhance speed, accuracy, and overall efficiency. The marriage of automation and stamping technology results in increased production rates while maintaining the high quality demanded by the automotive sector.

Environmental Considerations:

In a world increasingly conscious of environmental impact, automotive stamping tools are also making strides towards sustainability. The use of eco-friendly materials and the implementation of energy-efficient processes contribute to reducing the carbon footprint of manufacturing operations. Additionally, innovations in recycling and waste reduction within the stamping process align with the automotive industry’s commitment to sustainable practices.

Conclusion:

As the automotive industry continues to evolve, automotive stamping tools stand as a testament to the marriage of precision engineering and technological innovation. From their humble beginnings as manual tools to the sophisticated, automated systems of today, stamping tools play a pivotal role in shaping the vehicles we drive. As automakers navigate the challenges of an ever-changing landscape, the significance of these tools remains unwavering, ensuring that the future of automotive manufacturing is built on a foundation of precision, efficiency, and sustainability.

Post time: Mar-01-2024

.png)

.png)