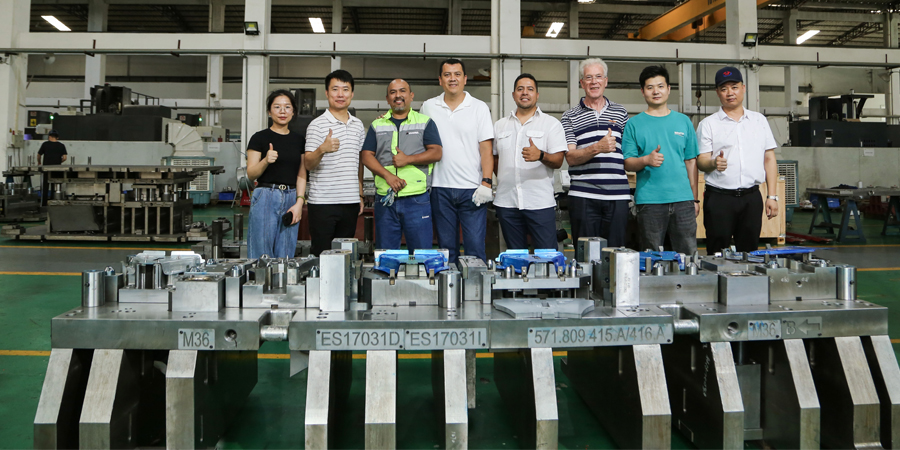

Customers who have cooperated for 10 years come to our stamping die factory to inspect the automotive stamping dies they ordered.

How to choose a stamping die manufacturer?

Choosing the right stamping die manufacturer is a critical decision that can significantly impact the quality and efficiency of your manufacturing process. Here are the steps to help you choose a stamping die manufacturer:

Define Your Requirements:

Before you start searching for a manufacturer, clearly define your project’s requirements. Understand the materials you’ll be working with, the expected production volume, the specific operations the dies need to perform, and the required tolerances.

Research and Identify Potential Manufacturers:

Start by researching and identifying potential stamping die manufacturers. You can use various sources for this, including online directories, industry associations, recommendations from peers, and trade shows.

Check Experience and Reputation:

Look for manufacturers with a proven track record and a good reputation in the industry. Consider factors like the number of years in business, the types of projects they’ve worked on, and their customer reviews and testimonials.

Assess Capabilities:

Contact the potential manufacturers and assess their capabilities. Discuss your project’s specific requirements to ensure they have the expertise and equipment to meet your needs.

Request References:

Ask for references from the manufacturer. Contact these references to inquire about their experiences working with the manufacturer, including the quality of the dies produced and the manufacturer’s reliability.

Review Quality Control Practices:

Inquire about the manufacturer’s quality control practices and procedures. Ensure that they have robust quality assurance measures in place to deliver high-quality stamping dies.

Inspect Equipment and Technology:

Visit the manufacturer’s facility if possible to inspect their equipment and technology. Modern, well-maintained machinery is more likely to produce accurate and high-quality dies.

Verify Material Selection:

Discuss the type of material the manufacturer uses for making the dies. Ensure it is suitable for your application in terms of hardness, toughness, and wear resistance.

Check Customization Options:

If you have unique or custom requirements, discuss these with the manufacturer to determine their ability to accommodate your needs.

Assess Lead Times:

Inquire about the lead times for producing the stamping dies. Ensure that the manufacturer can meet your project timeline and production schedule.

Discuss Pricing and Payment Terms:

Clarify the pricing structure and payment terms. Be aware of any additional costs, such as tooling or setup fees, and discuss payment schedules.

Understand Warranty and After-Sales Support:

Discuss warranty terms and after-sales support. Understand what kind of support you can expect if issues arise with the dies after delivery.

Consider Location and Logistics:

Evaluate the manufacturer’s location and its impact on logistics and shipping costs. Proximity can be an advantage, but quality should be the primary consideration.

Review Communication and Responsiveness:

Assess the manufacturer’s communication and responsiveness. A responsive and accessible manufacturer can help address issues or questions effectively.

Compare Multiple Quotes:

Request quotations from multiple manufacturers. Compare not only the price but also the quality, capabilities, and service offered by each manufacturer.

Visit the Facility:

If possible, visit the manufacturer’s facility to get a firsthand look at their operations, quality control, and work environment.

Finalize the Selection:

Based on your assessment and comparisons, choose the manufacturer that best meets your requirements, aligns with your project goals, and provides the best value.

Choosing the right stamping die, manufacturer requires careful research and due diligence to ensure that the dies produced meet your project’s requirements and quality standards.

Post time: Oct-18-2023

.png)

.png)