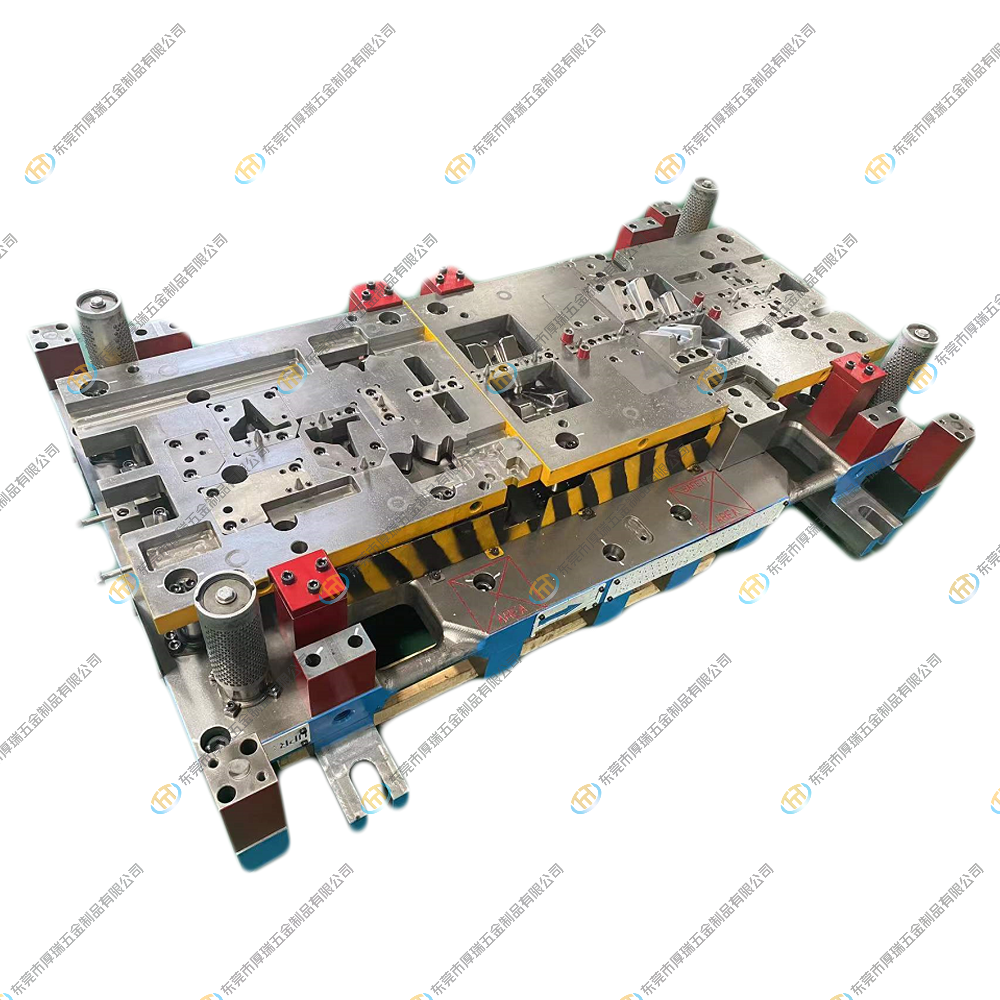

High Precision Prog tool Sheet Metal Deep Drawing Die Producer

Video

Essential details

|

Die type: |

Progressive die |

|

Part material: |

GMW3032M-ST-S-420LA-HD60G60G-U |

|

Die size: |

1760L * 1100M * 580H |

|

Mould Life: |

5-10 Years |

|

Certification: |

ISO9001 |

About US

Introduction

The application range of automotive Progressive die is very wide, including body parts, engine parts, chassis parts and so on. Especially in the field of automobile welding, the application of Progressive die is more extensive. For example, the Progressive die of the car body can combine multiple forming processes into one, and complete various processing operations in the same mold, which greatly reduces the manufacturing cost and production cycle.

TTM has many years of mature experience and technology in manufacturing Progressive die for automobiles. We can provide customers with high-quality products and one-stop services

Our Working Flow

1. Received the purchasing order -——-> 2. Design -——-> 3. Confirming the drawing/solutions -——-> 4. Prepare the materials -——-> 5. CNC -——-> 6. CMM -——-> 6. Assembling -——-> 7. CMM-> 8. Inspection -——-> 9. (3rd part inspection if need) -——-> 10. (internal/customer on site) -——-> 11. Packing(wooden box) -——-> 12. Delivery

Manufacturing Tolerance

1. The Flatness of Base Plate 0.05/1000

2. The Thickness of Base Plate ±0.05mm

3. The Location Datum ±0.02mm

4. The Surface ±0.1mm

5. The Checking Pins and Holes ±0.05mm

-300x3001.png)

.png)

.png)