One Stop Service Metal Tooling Supplier Stamping Mould Stamping Part

Stamping Mould Video

Metal Stamping Die Specification

| Brand Name | OEM |

| Product Name | Metal Stamping Die/Mould |

| Tolerance | +0.002mm |

| Material | SKD11, SKD 61, Cr1 2MOV, D2, SKH9, RM56, ASP23 etc. |

| Design Software | AutoCAD, Solid works, PRO/E, UG |

| Standard | IS09001-2015 |

| Mould Type | Transfer Die, Single Stamping Die, Progressive die or according to Customer's requirements |

| First Trial | 15-25 days after mold drawing confirmed |

| Mould Life | 5-10 years if maintain the equipment well |

| Quality confirm | Can send strip layout of die, testing video, inspection certificate and sample of product |

| Package | PE bags and carton for products, wooden case for Die/mold, or as customer's requirements |

More about Stamping Die

Modern stamping die production is a large-scale continuous operation manufacturing mode. Due to the involvement and intervention of high technology, the stamping production mode has gradually evolved from the initial manual operation to integrated manufacturing.

Production process has gradually realized mechanization, automation, and toward the direction of intelligent, integrated development. The realization of automation of stamping operation reflects the advantages of safety, efficiency and material saving, which has become the development direction of stamping die production.

In our daily life, many utensils are stamped, such as stainless steel rice bowls. It consists of a round metal plate pressed by a mould on a press. Thus, cold stamping is a kind of metal pressure processing method that exerts pressure on various metal (or non-metal) plates to separate or deform them at room temperature (cold state).

It is not only in many new technology, new technology in the production of a wide range of applications, such as spinning forming, soft die forming, high energy rate forming, but also is a qualitative leap in the understanding and grasp of stamping process.

TTM Supply Ability

Supply Ability:500 Set/Sets per Year

Packaging & delivery

Packaging Details:

Wooden Case Packing

Sear Port:

ShenZhen

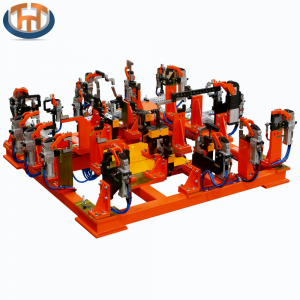

Picture Example:

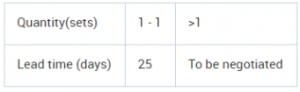

Lead time:

.png)

.png)