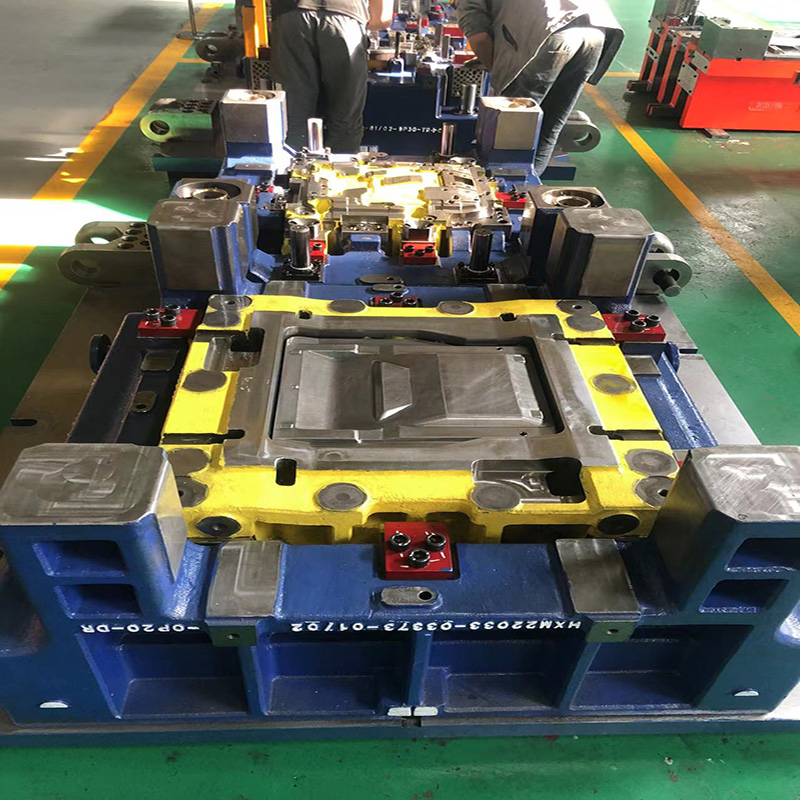

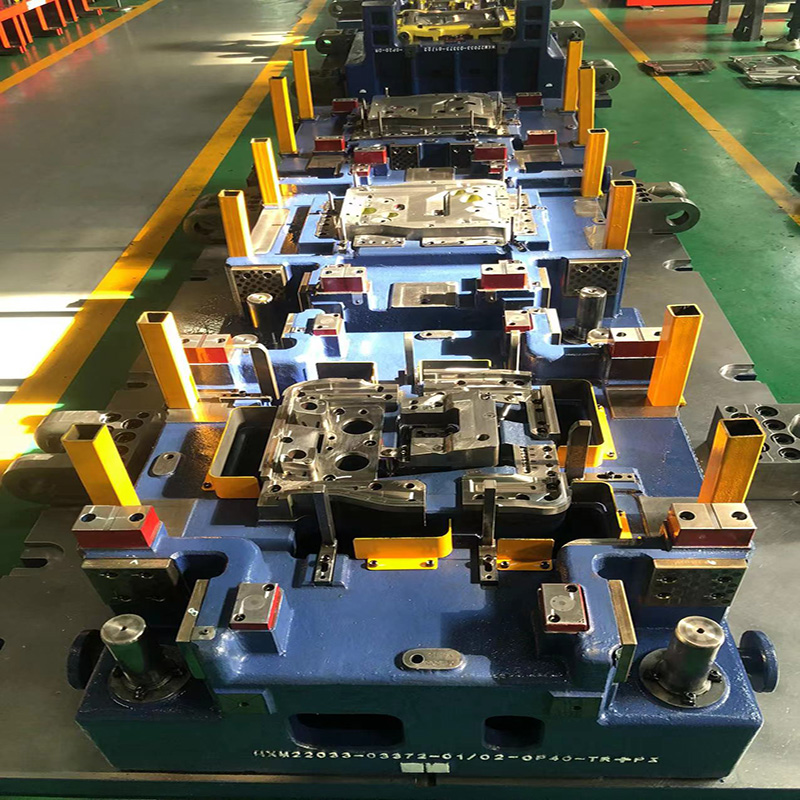

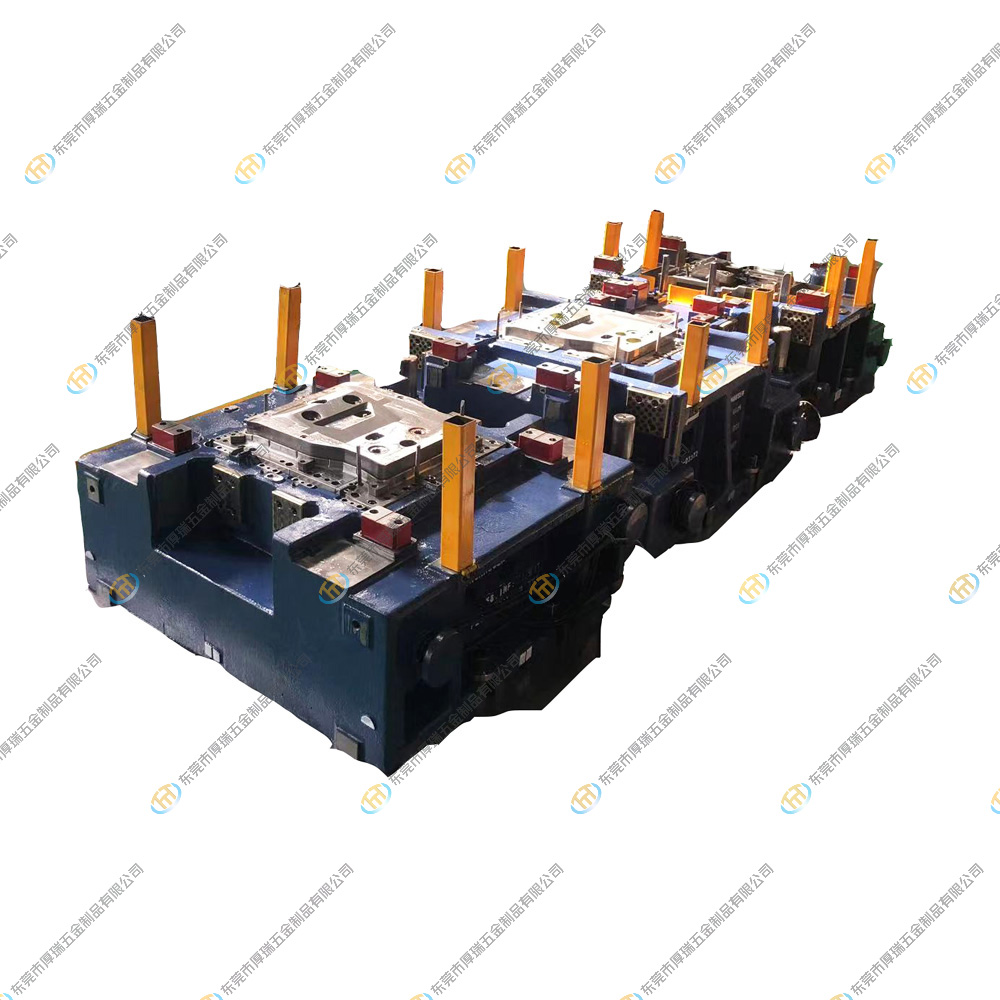

Factory Outlets High Quality Bending Cutting Punching Progressive Drawing Metal Stamping Dies

We now have a specialist, efficiency workforce to deliver excellent service for our purchaser. We always follow the tenet of customer-oriented, details-focused for Factory Outlets High Quality Bending Cutting Punching Progressive Drawing Metal Stamping Dies, Our company has been devoting that “customer first” and committed to helping customers expand their business, so that they become the Big Boss !

We now have a specialist, efficiency workforce to deliver excellent service for our purchaser. We always follow the tenet of customer-oriented, details-focused for China Stamping and Mold, “Good quality, Good service ” is always our tenet and credo. We take every effort to control the quality, package, labels etc and our QC will check every detail during producing and before shipment. We’re willing to establish long business relationship with individuals who seek the high quality merchandise and good service. We have set up a wide sales network across European countries, North of America, South of America, Middle East, Africa, East Asia countries.Please contact us now, you will find our professional experience and high quality grades will contribute to your business.

Video

Product Details

Detailed Introduction

The car seat system The hardware products have high requirements for section bright band, hole position accuracy, turning hole height and peripheral surface appearance. Among them, stamping technology is the key technology in the design of auto parts. The design of TTM car seat part mold stamping die can effectively reduce the cost of products and improve the quality of products , shorten the construction period, etc.

The Working Flow

1. Received the purchasing order -——-> 2. Design -——-> 3. Confirming the drawing/solutions -——-> 4. Prepare the materials -——-> 5. CNC -——-> 6. CMM -——-> 6. Assembling -——-> 7. CMM-> 8. Inspection -——-> 9. (3rd part inspection if need) -——-> 10. (internal/customer on site) -——-> 11. Packing(wooden box) -——-> 12. Delivery

Manufacturing Tolerance

1. The Flatness of Base Plate 0.05/1000

2. The Thickness of Base Plate ±0.05mm

3. The Location Datum ±0.02mm

4. The Surface ±0.1mm

5. The Checking Pins and Holes ±0.05mm

We now have a specialist, efficiency workforce to deliver excellent service for our purchaser. We always follow the tenet of customer-oriented, details-focused for Factory Outlets High Quality Bending Cutting Punching Progressive Drawing Metal Stamping Dies, Our company has been devoting that “customer first” and committed to helping customers expand their business, so that they become the Big Boss !

Factory Outlets China Stamping and Mold, “Good quality, Good service ” is always our tenet and credo. We take every effort to control the quality, package, labels etc and our QC will check every detail during producing and before shipment. We’re willing to establish long business relationship with individuals who seek the high quality merchandise and good service. We have set up a wide sales network across European countries, North of America, South of America, Middle East, Africa, East Asia countries.Please contact us now, you will find our professional experience and high quality grades will contribute to your business.

.png)

.png)