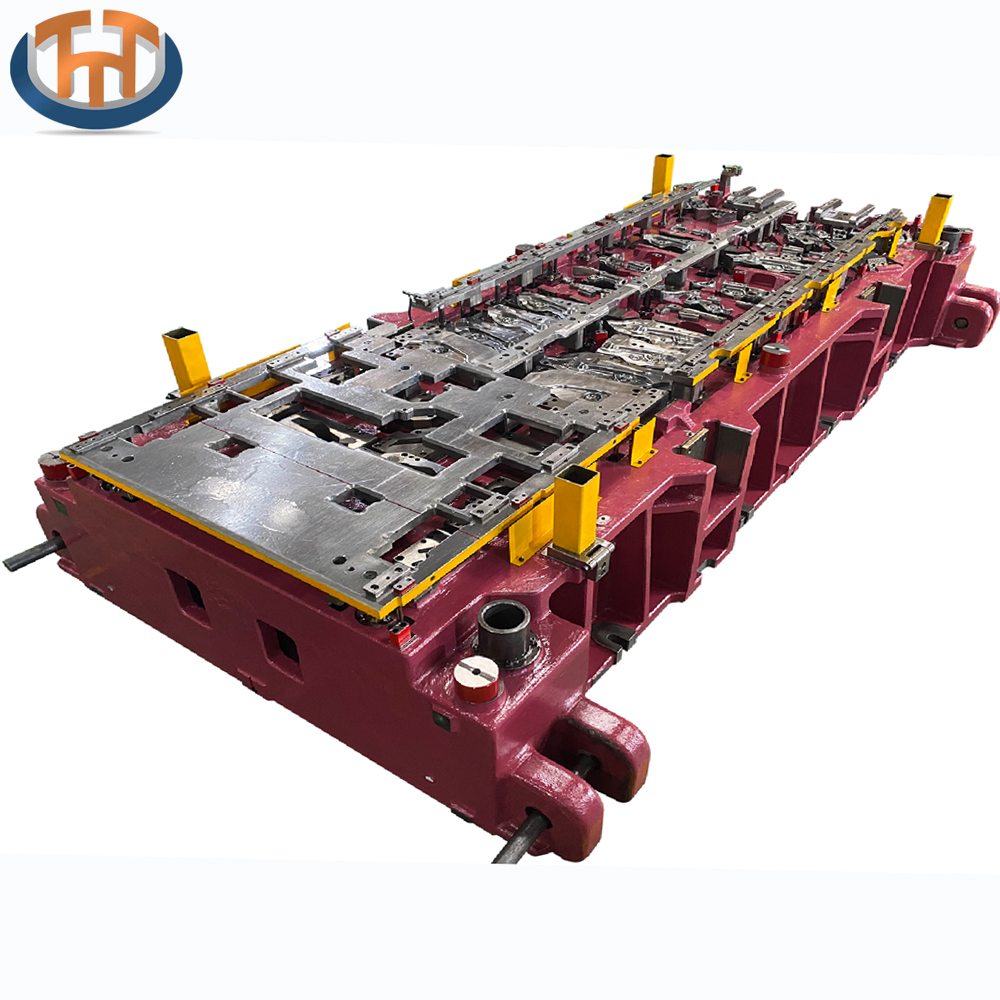

Supply OEM China Manufacturer Custom Stamping Dies Mold Base Die Set Progressive Dies Design and Manufacturing

We take “customer-friendly, quality-oriented, integrative, innovative” as objectives. “Truth and honesty” is our administration ideal for Supply OEM China Manufacturer Custom Stamping Dies Mold Base Die Set Progressive Dies Design and Manufacturing, We are able to customize the merchandise according in your prerequisites and we will pack it in your case when you purchase.

We take “customer-friendly, quality-oriented, integrative, innovative” as objectives. “Truth and honesty” is our administration ideal for China Mould Components and Mold Components, On today, we’ve got customers from all over the world, including USA, Russia, Spain, Italy, Singapore, Malaysia, Thailand, Poland, Iran and Iraq. The mission of our company is to deliver the highest quality products with best price. We’ve been looking forward to doing business with you!

Company Development

- In 2011, TTM was founded in ShenZhen.

- In 2012, Moving to DongGuan; Building cooperation relationship with Magna International Inc.

- In 2013 Introducing more advanced equipments.

- In 2016, Introduced large-scale CMM equipment and 5 axis CNC equipment; Cooperated with OEM Ford Completed Porsche, Lamborghini and Tesla CF projects.

- In 2017, Moving to current plant location; CNC was increased from 8 to 17 sets. Top Talent Automotive Fixtures & Jigs Co.Ltd was established

- In 2018, Cooperated with LEVDEO automotive and completed the automotion production line. 4-axis high-speed CNC was introduced, the total Qty of CNC reached 21.

- In 2019, Dongguan Hong Xing Tool & Die Manufacturer Co.,Ltd was established. (One stop service) Cooperated with Tesla Shanghai and Sodecia Germany. Built a new R&D laboratory for automation.

- In 2020, Cooperated with OEM ISUZU in SA ;Completed the RG06 One-Stop Service.

- In 2021, Moving forward with the quality belief to create a world-class enterprise.

- In 2022, TTM Group office was founded in Dongguan City, New CNC 4 axis*5 sets, New Press*630 tons, Hexagon Absolute Arm.

- In 2023, TTM is building a new plant for checking fixture&welding fixture business; adding one 2000T press.

Checking Fixture & Welding Jigs Factory (Total area: 9000m² )

Stamping Tools & Dies and Machined Parts Factory (Total area: 16000m²)

Overview

Essential details

Place of Origin: Guangdong, China Brand Name: TTM

Model Number. Stamping tool Shaping Mode: Die Casting

Product Material: Steel Product: Vehicle Mould

Product Name: Stamping tooling Material: Steel/casting/

Size: Customization or base on design standard components: Standard Lifter/can be customized

Usage: Automotive Die Set: Steel/Casting

Mould Life: 5-10 Years Mould base: Progressive/Transfer/Tandem

Certification: IS09001/TUV Weight: base on design

ISO Management System For Stamping Progressive Die

Our Automotive Progressive DieTeam

We have more than 352 employees, 80% of which are senior technical engineers. Tooling division: 130 employees, Welding jig division:60 employees, Checking fixture division:162 employees, We have a professional sales & project management team, long-term service overseas projects, from RFQ to production, shipment, after-sales, our team can handle all problems for our customers in Chinese, English and German Language.

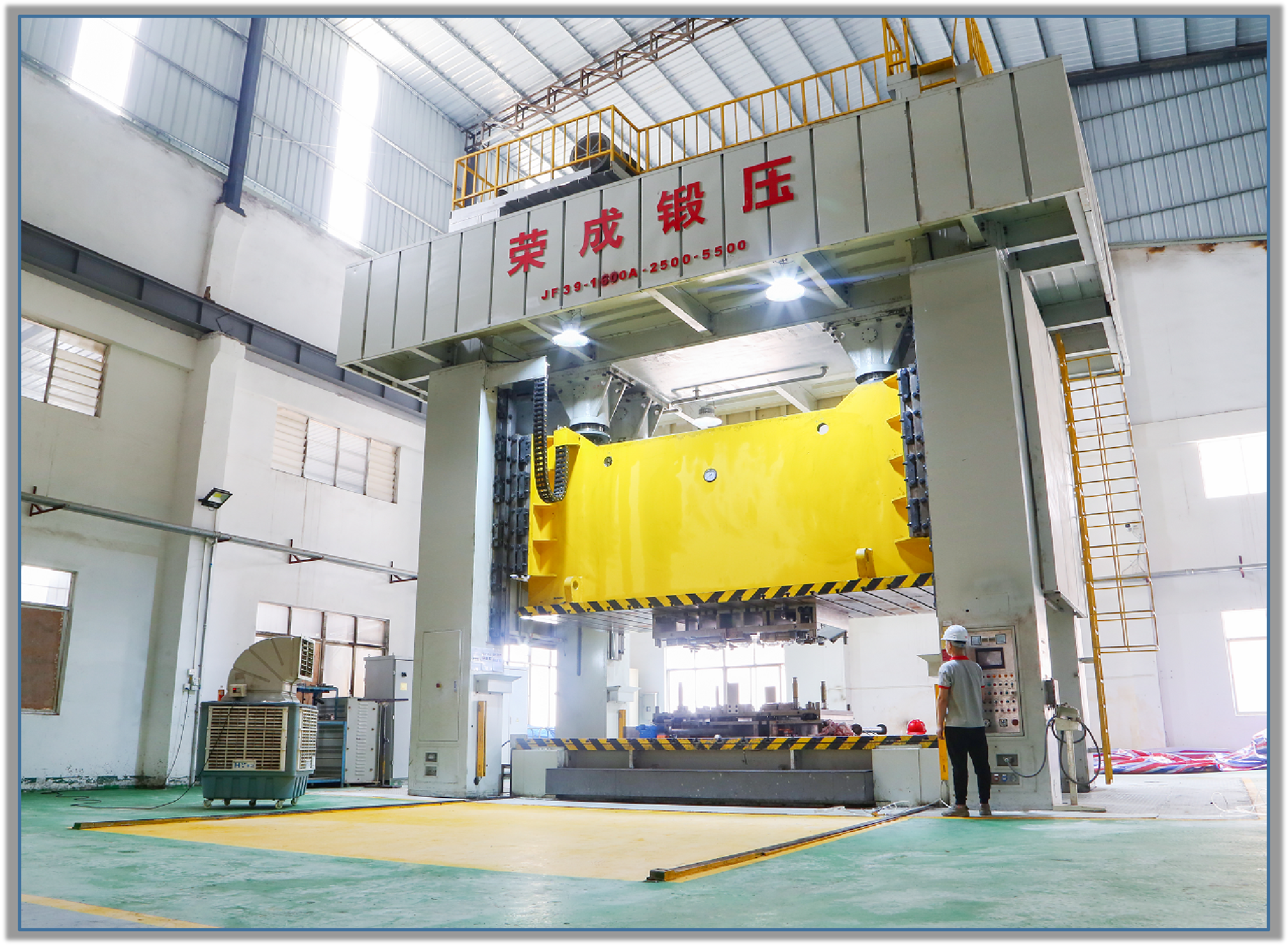

Tonnage 1250T: Bolster size :5500*2500 with coil feeder

CMM Measurement Center For Casting Progressive Die

Our good trained personnel will take care every time in every program we have. We can do every requirement from the customer, to have the biggest satisfaction in the CMM as well.

3Sets of CMM, 2 Shifts/Day(10hrs per shift Mon-Sat)

CMM, 3000*1500*1000 , Leader CMM, 1200*600*600 , Leader Blue-light Scanner

CMM, 500*500*400, Hexagon 2D Projector, Hardness TesterWe take “customer-friendly, quality-oriented, integrative, innovative” as objectives. “Truth and honesty” is our administration ideal for Supply OEM China Manufacturer Custom Stamping Dies Mold Base Die Set Progressive Dies Design and Manufacturing, We are able to customize the merchandise according in your prerequisites and we will pack it in your case when you purchase.

Supply OEM China Mould Components and Mold Components, On today, we’ve got customers from all over the world, including USA, Russia, Spain, Italy, Singapore, Malaysia, Thailand, Poland, Iran and Iraq. The mission of our company is to deliver the highest quality products with best price. We’ve been looking forward to doing business with you!

.png)

.png)