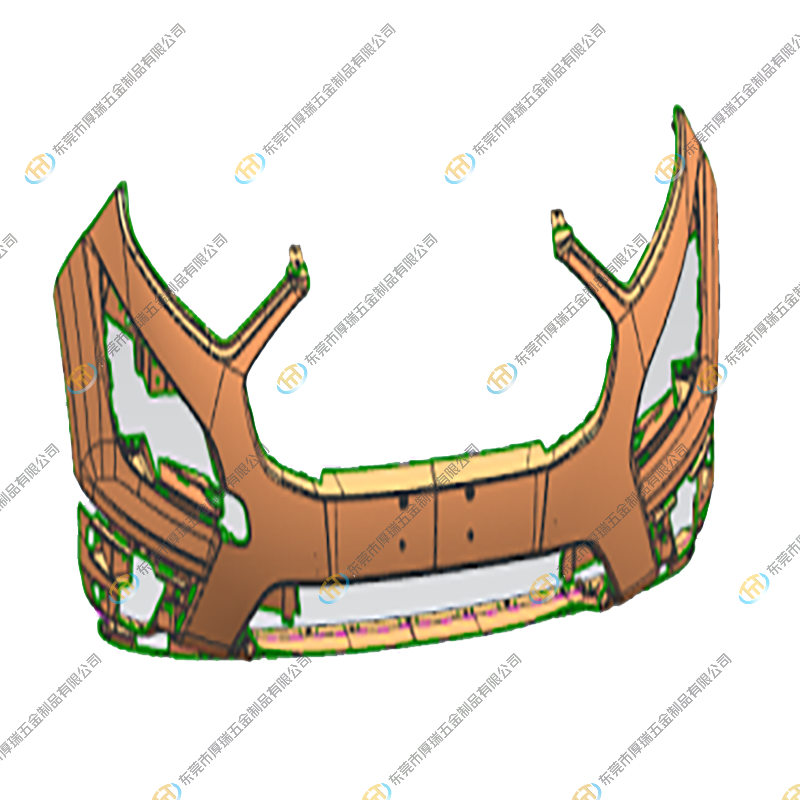

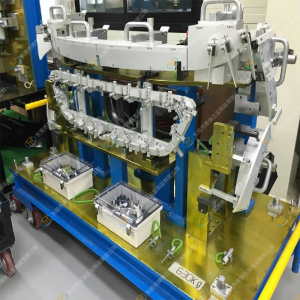

Automotive Plastic Part Assembly Checking Fixtures Front Bumper ASSY Gauges Manufacturers

Video

Specification

|

Fixture Type: |

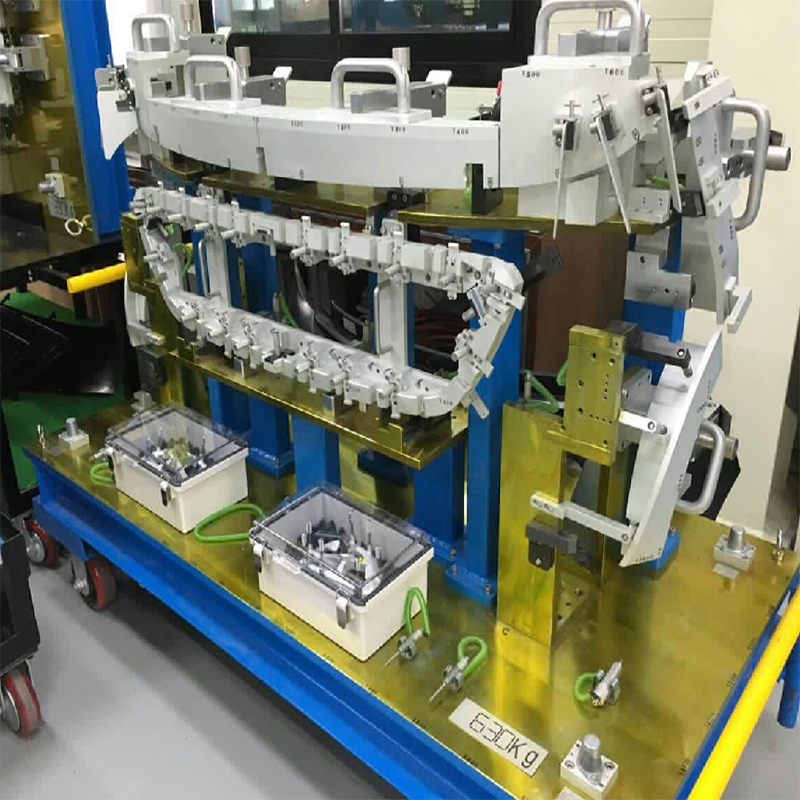

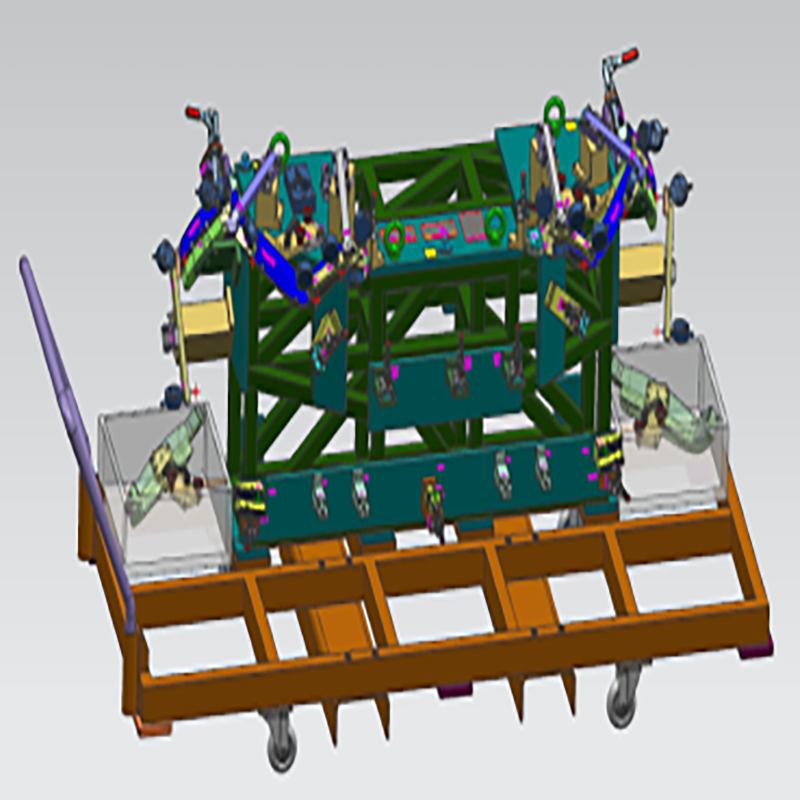

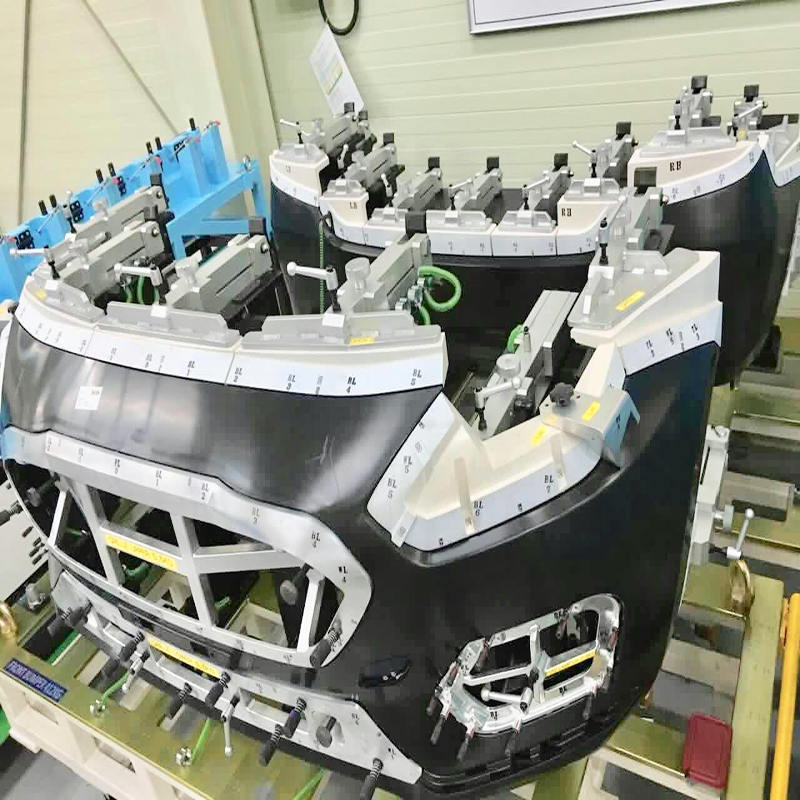

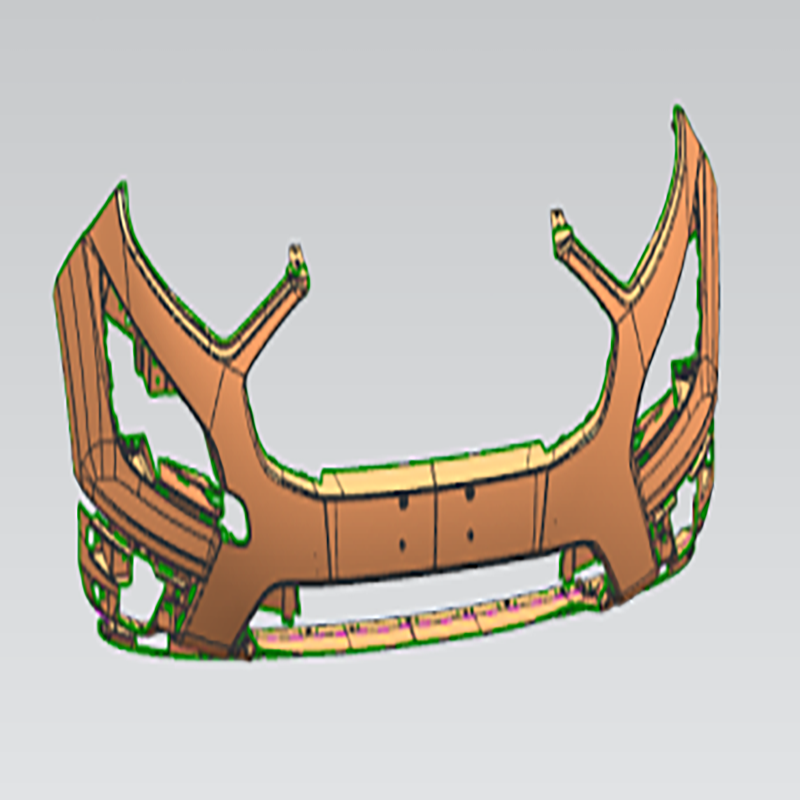

Checking Fixture for Front Bumper |

|

Size: |

2500*1100*1500mm |

|

Export Country: |

Russia |

Product Details

Detailed Introduction

Checking Fixture is often used in industrial production of a measuring tool, these measuring tools can not only measure the size of the parts, but also measure the shape of the parts and its position characteristics, will do a full range of parts detection, in fact, it is a special tool to detect the quality of parts.

According to the test object, it can be divided into stamping single checking fixture, component assembly inspection tool and combination gauge. Our front bumper assy checking fixture is not only can be used in the production process of parts, some parts checking also can be used for measuring the finished parts of the tool, it is a special tool that can be used continuously.

Size of this front bumper assy CF is 2500*1100*1500.

The Working Flow

1. Received the purchasing order -——-> 2. Design -——-> 3. Confirming the drawing/solutions -——-> 4. Prepare the materials -——-> 5. CNC -——-> 6. CMM -——-> 6. Assembling -——-> 7. CMM-> 8. Inspection -——-> 9. (3rd part inspection if need) -——-> 10. (internal/customer on site) -——-> 11. Packing(wooden box) -——-> 12. Delivery

Manufacturing Tolerance

1. The Flatness of Base Plate 0.05/1000

2. The Thickness of Base Plate ±0.05mm

3. The Location Datum ±0.02mm

4. The Surface ±0.1mm

5. The Checking Pins and Holes ±0.05mm

.png)

.png)