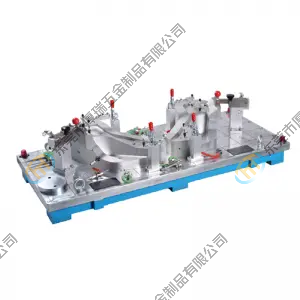

Special Jig And Fixture For Welding , Welding Jig Inspection Fixture Components

Video

|

Base Support: |

Steel |

Base Material: |

Al |

|

Templates Material: |

Steel |

Weight: |

430KG |

|

Size: |

1320*1000*860mm |

Handle: |

Automation |

Automotive Part Special Customized Welding Jig Inspection Fixtures

It must be possible to reach efficient testing periods with the gauge. Especially the processes ,emoving,inspection,must be actable time-saving. Therefore every potential for optimization concerning construction should be communicated to GEDIA by supplier.

As a result the construction- and building-process of gauges could become better step by step.

Our production detail

| Items | ||

| 1 | Base Material | Al |

| 2 | Application | Stamping Parts |

| 3 | Surface treatment | Oxidation/Paint |

| 4 | Processing Precision | 0.15 |

| 5 | Accuracy for Other Profiles | 0.1 |

| 6 | Accuracy for Datum Hole | ±0.05 |

| 7 | Certificate | ISO 9001:2008 |

| 8 | CMM certification | Yes |

| 9 | Software | Catia, UG, CAD, STP |

| 10 | Specification | 1320*1000*860mm |

| 11 | Packing | Wooden Box |

Material

1.The Location Datum ±0.05mm

2.The Surface ±0.15mm

3.The Checking Pins and Holes ±0.1mm

Process

CNC Machining(Milling/Turning), Grinding

Black Anodized Treatment

Design Hours(h): 60h

Quality Control

CMM (3D Coordinate Measuring Machine), HR-150 A Hardness Tester

Lead time & Packing

2 months after 3D design approved

15 days via sea: HMM

Standard Export Wooden Case

Quality Policy

Legal Compliance

Customer First

Total Quality Control

System Operation

Continuous Improvement

More

We’re dedicated to providing our customers with high quality, practical, and cost-effective solutions that serve a variety of needs in the areas of checking fixtures, welding fixtures and jigs! We will work closely with customers to define their needs and assess critical design factors such as functionality, productivity requirements.

.png)

.png)