Hemming Die Revolutionizes Automotive Industry

In a breakthrough for the automotive manufacturing sector, a cutting-edge hemming die is set to redefine the way sheet metal is shaped, enhancing precision and efficiency across the production line. Developed by a team of engineers at InnovateTech Solutions, the innovative hemming die promises to streamline the manufacturing process, ultimately leading to higher-quality vehicle components.

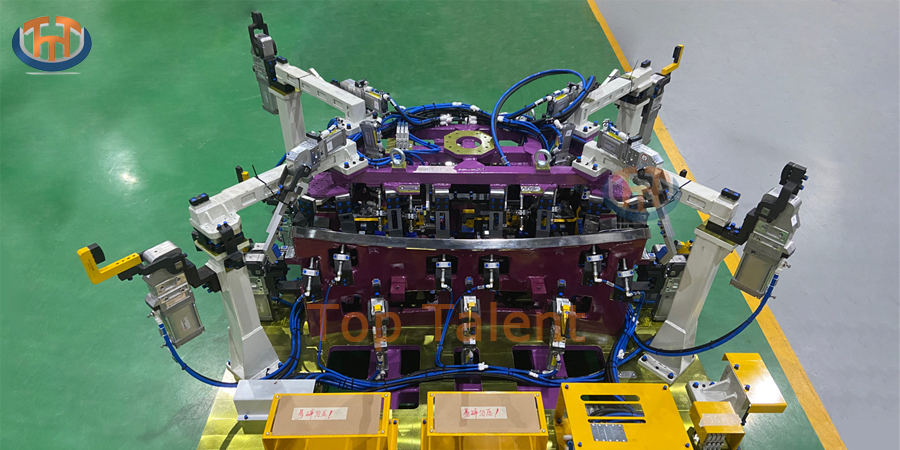

The hemming die, a pivotal tool in the sheet metal forming process is designed to fold and secure edges seamlessly, creating a smooth and polished finish. This latest iteration, dubbed the PrecisionHem 2024, incorporates state-of-the-art technology and materials to address the challenges faced by automotive manufacturers in achieving consistent and high-quality hemmed edges.

One of the standout features of the PrecisionHem 2024 is its adaptive control system, which utilizes artificial intelligence to analyze and adjust the hemming process in real time. This dynamic system ensures unparalleled accuracy, even when working with varying sheet metal thicknesses and compositions. The result is a significant reduction in defects and inconsistencies, contributing to a higher overall product standard.

Engineers at InnovateTech Solutions emphasize that the PrecisionHem 2024 is not only a tool for efficiency but also a solution for environmental sustainability. By minimizing material waste and optimizing the use of resources, automotive manufacturers adopting this advanced hemming die can contribute to a more eco-friendly production process.

The PrecisionHem 2024 also boasts a modular design, allowing for easy integration into existing manufacturing setups. This adaptability ensures that automotive plants can incorporate the new technology without undergoing extensive overhauls, minimizing downtime and maximizing the return on investment.

Industry experts have welcomed the introduction of the PrecisionHem 2024, recognizing its potential to revolutionize automotive manufacturing. The tool’s ability to enhance the structural integrity of hemmed components is particularly noteworthy, as it contributes to the overall safety and durability of the final product.

Leading automotive manufacturers, including major players in the industry, have expressed interest in adopting the PrecisionHem 2024 into their production processes. Preliminary trials have yielded promising results, with a notable increase in production efficiency and a decrease in the need for rework.

The development team at InnovateTech Solutions anticipates that the PrecisionHem 2024 will not only set a new standard for hemming die technology but will also open doors for further innovation in automotive manufacturing. The integration of smart technology and adaptive control systems is expected to pave the way for a new era of precision engineering in the sector.

As the automotive industry continues to evolve, advancements in manufacturing processes play a crucial role in maintaining competitiveness and meeting the demands of a rapidly changing market. The PrecisionHem 2024 stands as a testament to the ongoing commitment of engineers and innovators to push the boundaries of what is possible in automotive manufacturing.

In conclusion, the introduction of the PrecisionHem 2024 hemming die marks a significant milestone in automotive manufacturing, promising enhanced efficiency, sustainability, and product quality. As this cutting-edge technology gains traction across the industry, it is poised to shape the future of sheet metal forming and contribute to the evolution of the automotive sector.

Post time: Jan-20-2024

.png)

.png)