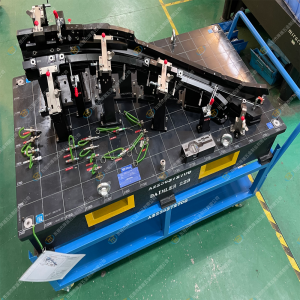

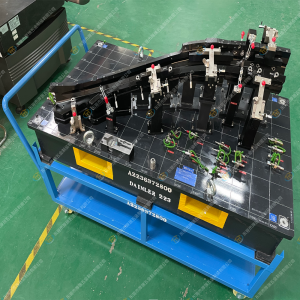

Form Inspection Go/No-Go Gages Roof Frame Left A Pillar Single Metal Part Checking Fixture

Video

Essential details

|

Fixture Type: |

Attribute/CMM Combo Fixture |

|

Part Name: |

Roof Frame left A pillar LH&RH |

|

Export Country: |

Germany |

|

Qty: |

2 Sets in Total |

|

Material: |

Metal |

About US

Introduction

The fixture is mainly used to check whether the size, shape, position and other parameters of the A-pillar on the left side of the roof frame of the car meet the design requirements. It can help manufacturers improve production efficiency and product quality, and reduce production accidents and quality problems caused by A-pillar dimensions that do not meet the requirements.

The design and manufacture of Roof Frame Left A Pillar Checking Fixture need to take into account the different car models, so it is usually customized. During the manufacturing process, it is necessary to design and process according to the model drawings and testing requirements provided by the customer. At the same time, TTM's inspection fixture manufacturing needs to be strictly controlled in accordance with the ISO9001 quality management system to ensure the accuracy and stability of the fixture.

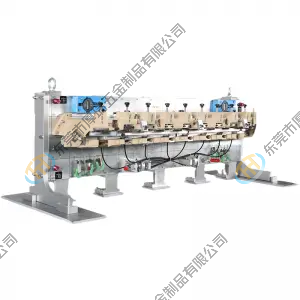

Our Working Flow

1. Received the purchasing order -——-> 2. Design -——-> 3. Confirming the drawing/solutions -——-> 4. Prepare the materials -——-> 5. CNC -——-> 6. CMM -——-> 6. Assembling -——-> 7. CMM-> 8. Inspection -——-> 9. (3rd part inspection if need) -——-> 10. (internal/customer on site) -——-> 11. Packing(wooden box) -——-> 12. Delivery

Manufacturing Tolerance

1. The Flatness of Base Plate 0.05/1000

2. The Thickness of Base Plate ±0.05mm

3. The Location Datum ±0.02mm

4. The Surface ±0.1mm

5. The Checking Pins and Holes ±0.05mm

.png)

.png)