Discount wholesale Car Checking Fixture/Jig and Check Gauge for Automotive Interior & Exterior Fittings

We can normally fulfill our respected consumers with our great excellent, great value and good provider due to we’re much more specialist and extra hard-working and do it in cost-effective way for Discount wholesale Car Checking Fixture/Jig and Check Gauge for Automotive Interior & Exterior Fittings, To supply prospects with superb equipment and providers, and constantly build new machine is our company’s organization objectives. We look ahead for your cooperation.

We can normally fulfill our respected consumers with our great excellent, great value and good provider due to we’re much more specialist and extra hard-working and do it in cost-effective way for China Checking Fixture and Checking Jig, We focus on providing service for our clients as a key element in strengthening our long-term relationships. Our continual availability of high grade solutions in combination with our excellent pre-sale and after-sales service ensures strong competitiveness in an increasingly globalized market.

Video

Function

As a part of the car interior, the car luggage cover plate is installed on the spare tire slot in the trunk, which plays a supporting and beautiful role. The trunk of the car plate in the process of production and processing, its size and shape flat surface flatness is the key indicators of its product quality, therefore, provides a simple and reasonable structure, both can guarantee accuracy, and can improve the detection efficiency of the fixture, for car trunk cover plate production and processing is necessary.

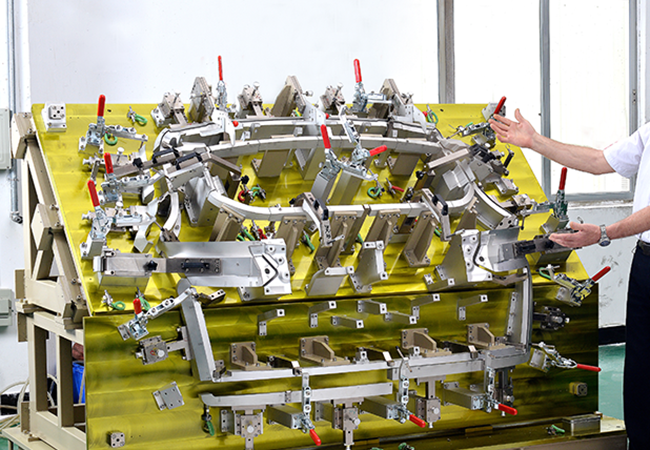

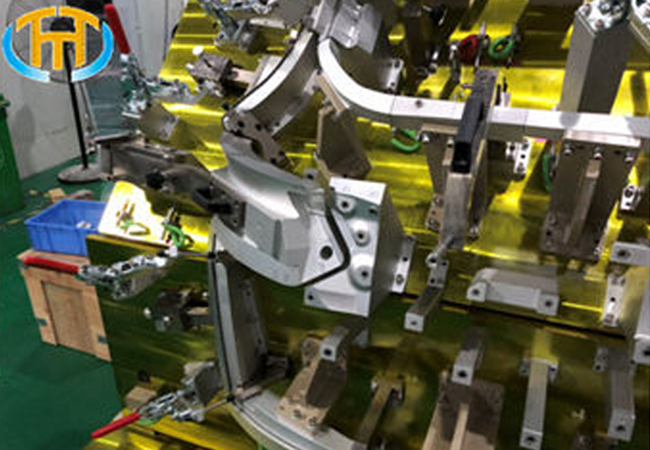

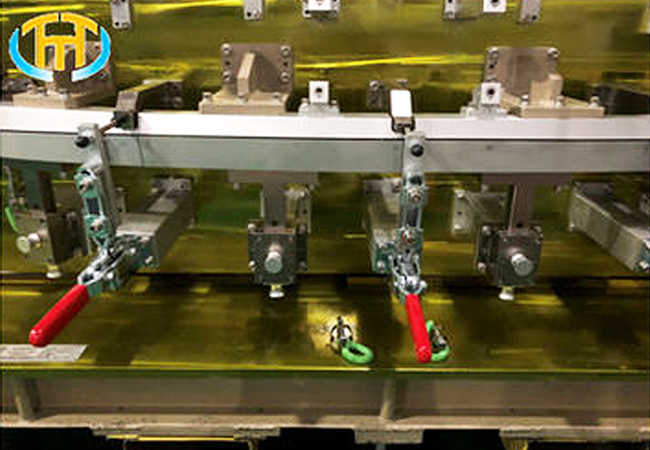

TTM Auto Trunk Lid Final Fixture is manufactuere by CNC machine and material come with steel and resin, this fixture also can be used as CMM holdidng fixture for auto parts, measurement jigs for plastic parts and metal parts.

Specification

|

Fixture Type: |

Auto Trunk Lid Final Fixture Part |

|

Size: |

5850x950x4300 |

|

Weight: |

3750 KG |

|

Material: |

steel+resin |

|

Surface treatment: |

Base Plate: Electroplating Chromium and Black Anodized |

Detailed Introduction

Auto Trunk Lid Final checking and matching Fixture relates to the field of automobile parts production and processing equipment, in particular to a checking tool for automobile trunk cover plate.

As a part of the car interior, the auto trunk lid is installed on the spare tire slot in the trunk, which plays a supporting and beautiful role. The trunk of the lid in the process of production and processing, its size and shape flat surface flatness is the key indicators of its product quality, therefore, provides a simple and reasonable structure, both can guarantee accuracy, and can improve the detection efficiency of the fixture, for car trunk Lid production and processing is necessary.

In line with the principle of the car trunk lid inspection tools, to ensure the detection accuracy, while saving manpower, improve work efficiency.

The utility model provides a new infrastructure as follows:

The upper surface of the bottom plate is provided with two groups of X direction simulation blocks and two groups of Y direction simulation blocks along the X axis direction and Y axis direction respectively. Four groups of simulation blocks are connected with the end of the enclosure workpiece placement area. Each group of simulation blocks are fixed with a horizontal direction of the first dial indicator and a vertical direction of the second dial indicator, the four corners of the bottom plate are fixed .

The Working Flow

1. Received the purchasing order -——-> 2. Design -——-> 3. Confirming the drawing/solutions -——-> 4. Prepare the materials -——-> 5. CNC -——-> 6. CMM -——-> 6. Assembling -——-> 7. CMM-> 8. Inspection -——-> 9. (3rd part inspection if need) -——-> 10. (internal/customer on site) -——-> 11. Packing(wooden box) -——-> 12. Delivery

Lead time & Packing

45 days after 3D design approved

5 days via express: FedEx by Air

Standard Export Wooden Case

We will add fixing wooden block inside cases to make sure fixture safety in shipping. Desiccant and plastic wrap will be used to keep the checking fixture from moisture in shipping.

We can normally fulfill our respected consumers with our great excellent, great value and good provider due to we’re much more specialist and extra hard-working and do it in cost-effective way for Discount wholesale Car Checking Fixture/Jig and Check Gauge for Automotive Interior & Exterior Fittings, To supply prospects with superb equipment and providers, and constantly build new machine is our company’s organization objectives. We look ahead for your cooperation.

Discount wholesale China Checking Fixture and Checking Jig, We focus on providing service for our clients as a key element in strengthening our long-term relationships. Our continual availability of high grade solutions in combination with our excellent pre-sale and after-sales service ensures strong competitiveness in an increasingly globalized market.

.png)

.png)