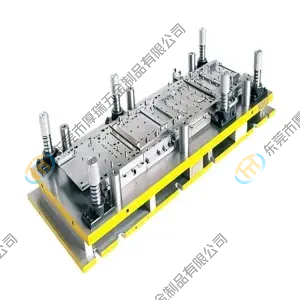

TTM Automotive Sheet Metal Stamping Presses and Progressive Stamping Die

TTM Stamping Die Video

Advantages of stamping die manufacturing

Compared with wire cutting, stamping die manufacturing has a series of advantages such as high production efficiency, low processing cost, high material utilization rate, stable dimensional accuracy of products, simple operation, easy to realize mechanization and automation, etc., which is especially suitable for mass production.

As a very important processing method in modern industry, stamping die is used to produce all kinds of sheet metal parts. It has the unique advantages of light weight, high stiffness, high strength, good interchangeability, low cost, easy to realize mechanical automation and high production efficiency. This stamping die method is an advanced manufacturing technology that other processing methods can not compare and replace. With strong competitiveness in the manufacturing industry, it is widely used in automobile, energy, machinery, information production, aerospace, national defense industry and daily life and other fields.

TTM Stamping Presses Supply Ability

Supply Ability:500 Set/Sets per Year

Packaging & delivery

Packaging Details:

Wooden Case Packing

Port:

ShenZhen

Picture Example:

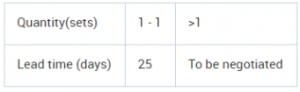

Lead time:

Video Description

TTM Stamping Tool Description

| Brand Name | OEM |

| Product Name | Metal Stamping Die/Mould |

| Tolerance | +0.002mm |

| Material | SKD11, SKD 61, Cr1 2MOV, D2, SKH9, RM56, ASP23 etc. |

| Design Software | AutoCAD, Solid works, PRO/E, UG |

| Standard | IS09001 |

| Mould Type | Compound Stamping Die, Single Stamping Die, Progressive die or according to Customer's requirements |

| First Trial | 15-25 days after mold drawing confirmed |

| Mould Life | Depends on customer S production capacity |

| Quality confirm | Can send strip layout of die, testing video, inspection certificate and sample of product |

| Package | PE bags and carton for products, wooden case for Die/mold, or as customer's requirements |

-300x3001.png)

.png)

.png)