The component positioning element of the jig is in contact with the positioning reference of the workpiece.Used to determine the correct position of the workpiece in the jig.Clamping is a device for clamping workpieces,Keep the workpiece in a fixed position in the jig during measurement.The element is used to determine the relative position of the jig and the probe.Jig body is used to connect the clamping device components and devices, it becomes a whole of the basic parts.

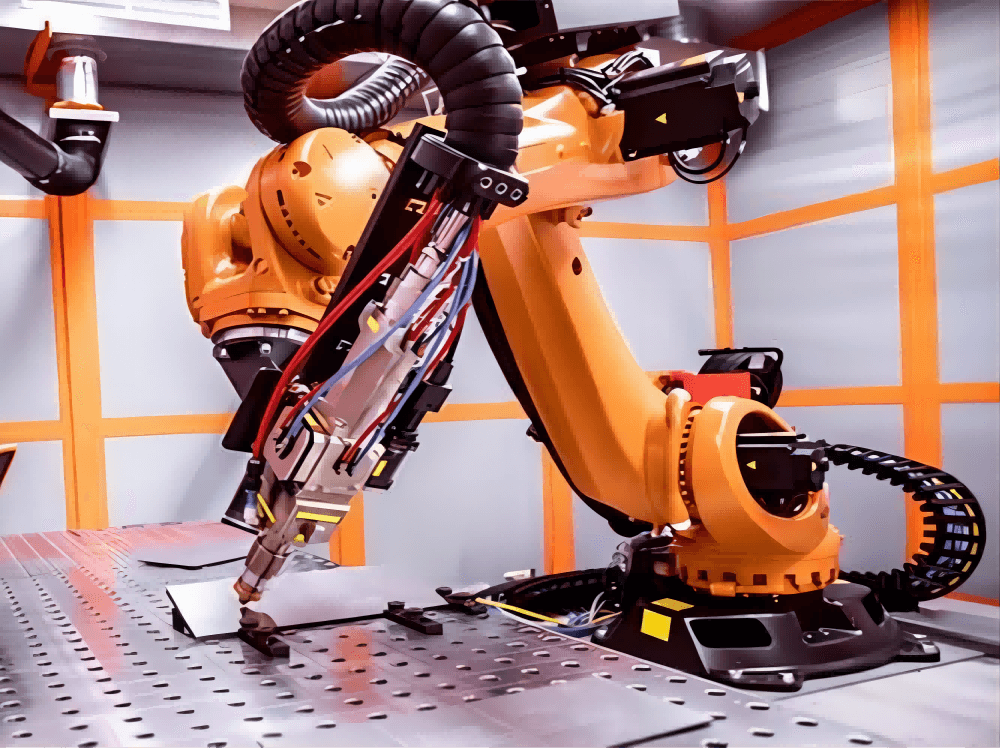

The above components are that any jig must have a positioning element and a clamping device,which are the key to ensuring precision and the purpose of “positioning and clamping” the workpiece. The basic requirement of jig is to ensure the measuring precision of workpiece stably.Reduce the measurement cost of workpiece,shorten auxiliary time, improve labor productivity.Special components are used to enable the workpiece to be quickly clamped into the jig.The jig could also be clamped and adjusted quickly through special devices such as positioning key, cutter block and guide sleeve.In addition, it could also use multiple pieces, multi-position, multi-speed, power increase, motor and other clamping devices.Easy to ensure accuracy and stability, the use of special jig could reduce labor intensity and ensure to safe production.The use of jig could reduce the technical level of workers, so that workers operate conveniently, production safety and reduce manual labor.

Jig must be designed so that the measurement accuracy, productivity, labor conditions and economy of several aspects to achieve dialectical unity.The measurement precision is the basic requirement,In order to improve the productivity, advanced structure and mechanical transmission device are adopted, which will often increase the manufacturing cost of jig.However, when the batch of the workpiece increases to a certain scale, the economic efficiency obtained by the decrease of the working hours of a single piece will be compensated, thus reducing the manufacturing cost of the workpiece.Therefore, the design of the jig , its complexity and workpiece efficiency must adapt to the production scale, in order to obtain a good economic effect.

However, any technical measures will meet certain special conditions. When designing jigs, the quality, productivity, labor conditions and economy will be considered.Sometimes there is an emphasis. For example, the measurement with high requirements for position accuracy is often focused on the measurement accuracy.In the process of redesigning, it is necessary to conduct in-depth investigation and research on the actual production, extensively solicit the opinion of the demander, draw on advanced experience and draw up the preliminary design scheme on this basis, after consideration, and then formulate a reasonable scheme for the jig design.

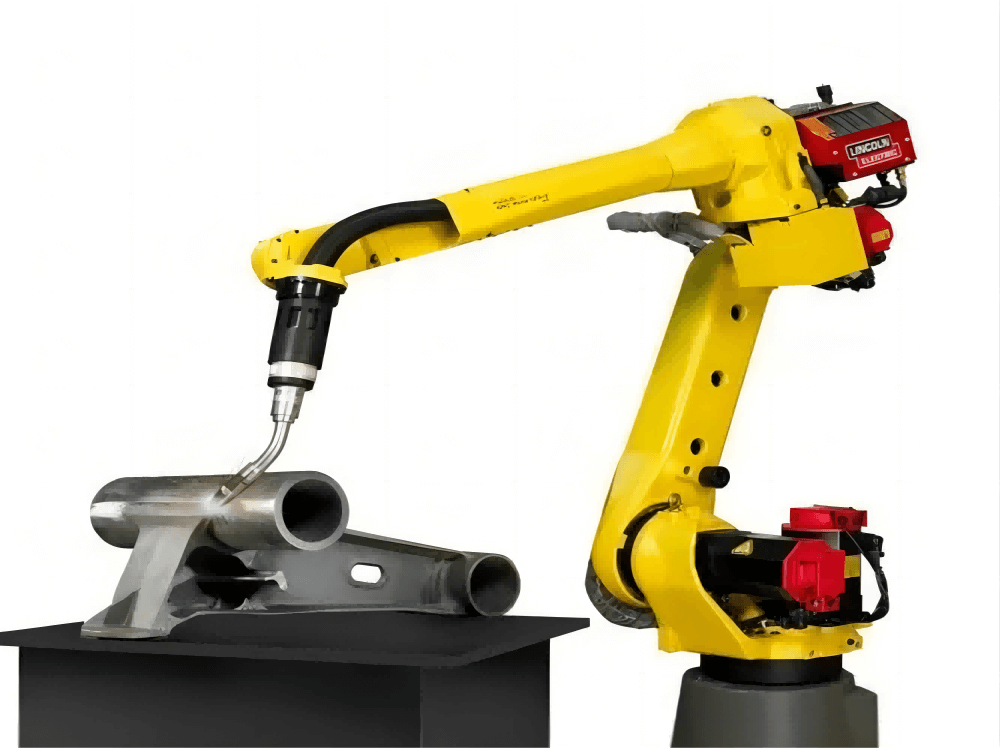

Jig is an important process equipment in mechanical manufacturing. In order to ensure measuring accuracy and improve efficiency,clamping force must be applied on workpiece and machine tool, which is called clamping.Positioning and clamping two comprehensive known as clamping, the completion of workpiece clamping process equipment.

The classification of machine tool jig could be divided into two categories according to the degree of universalization.The first kind of machine tool jig is made by machine tool accessory factory or special tool factory.

Post time: Feb-04-2023

.png)

.png)