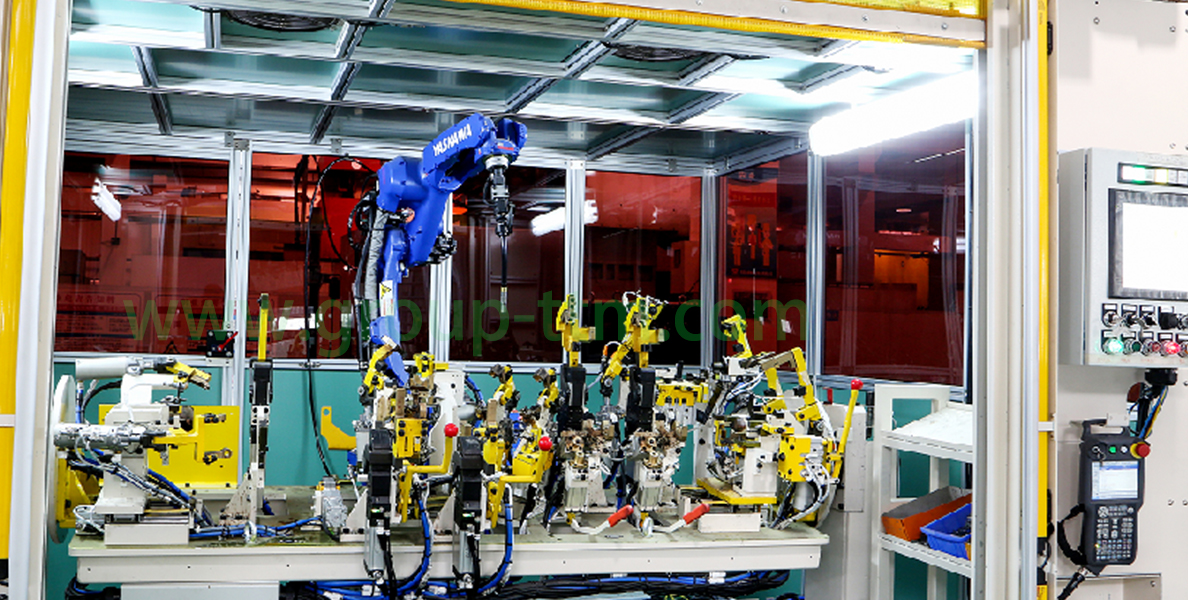

In industrial production, in order to ensure the accuracy of welding, we often need to use welding fixtures. Similarly, automobile production also requires the use of automobile welding fixtures to prevent welding deformation. So what is the function of the automobile welding fixture?

1. The heavy work of positioning, clamping and workpiece turning when manually assembling parts is replaced by mechanical devices, which improves the working conditions of workers.

2. Accurate and reliable positioning and clamping can reduce or even cancel the blanking and marking work. The dimensional deviation of the product is reduced, and the accuracy and replaceability of the parts are improved.

3. Keep the workpiece in the best welding position, the formability of the weld seam is good, the process defects are obviously reduced, and the welding speed is improved.

4. It can bring greater economy to the company, and the cost\time of special tooling invested in each product change can be almost no longer spent. The device is easy to operate and safe to use, and users can quickly splice out tooling with different requirements according to their needs.

5. Automobile welding fixtures can expand the scope of use of advanced technology methods and promote the comprehensive development of mechanization and automation of welded structure production.

6. The performance is very stable. If the parts are damaged due to improper use, there is no need to scrap the whole table, and a single part can be replaced with very little cost.

7. Automobile welding fixtures can effectively prevent and reduce welding deformation.

Therefore, automobile welding fixtures play an important role in the production and manufacture of automobiles.

Post time: Jun-23-2023

.png)

.png)