TTM Group was established in 2017 as a manufacture of metal stamping dies,fixture&jigs, automation equipment for the automotive industry.In TTM,we have rich experience in steel&casting progressive tool,transfer and single tool , products are widely used in automotive structure part,Seating,under-body, chassis etc.And we want to share that “How to reduce the cost of automobile stamping dies?”

This article mainly analyzes the idea of reducing the cost of automobile stamping dies, so as to provide technical guidance for enterprises in need, and help enterprises complete the cost control work of automobiles.

Combined with economics, technology and other aspects, the cost reduction of automobile stamping dies is mainly divided into the following ideas

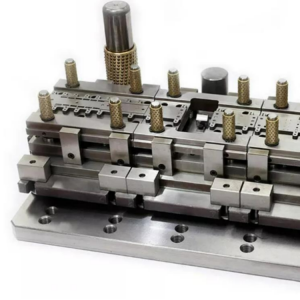

1. Divide the material grade of the mold

If the automobile industry wants to completely reduce the cost of stamping dies, it needs to eliminate the waste of materials in production. The automobile industry can classify the stamping dies according to the quality of the materials of the stamping dies and divide them into grades, so that the automobile industry can choose different grades of stamping dies according to the needs of automobile production, which can not only improve the work efficiency of automobile production, but also make the automobile meet Greater production needs. In the production process, if the automobile industry wants to control the production quantity, it can change the grade selection of stamping dies, which can avoid large economic losses

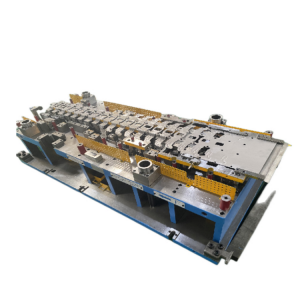

2. Guarantee the standardization of operation

In the process of automobile production, the requirements for the use of stamping dies are relatively high. Not only do operators need to choose standard operating tools, but they also need to be proficient in the use of stamping dies to avoid waste of stamping dies in the production process. Because the production workshop needs to produce a large number of stamping dies, which will increase the cost of automobile production, the automobile industry needs to complete the production of dies according to the actual demand for automobile dies. At the same time, the automotive industry can process the used stamping dies to improve the utilization efficiency of materials and promote the sustainable development of the automotive industry. Therefore, the automotive industry needs to ensure the operating standards of operators to strengthen the cost control of the automotive industry.

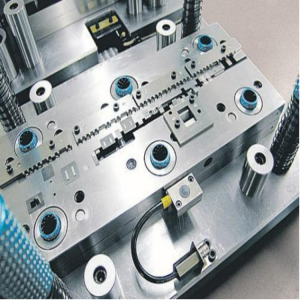

3. Optimization of complete stamping die

In order to improve the utilization rate of stamping dies in the automobile production process, the automobile industry can make appropriate improvements to the stamping dies, which can reduce the waste of materials in the production process. In order to reduce the waste of production materials, the automobile industry can adjust the structure of the stamping die. For example, increasing the contact area between the stamping die and the material can be achieved mainly by installing double-slot rails, which can not only disperse the gravity on the stamping die but also improve the stamping pressure. The use efficiency of molds can improve the production efficiency of automobiles. The automotive industry can complete the optimization of the stamping die according to the actual production needs, so as to achieve the best cost reduction effect.

Above are all we want to share in this article,hope can help you all!

Post time: Apr-04-2023

.png)

.png)