The automobile welding fixture is the same as the general welding fixture. Its basic structure is also composed of positioning parts, clamping parts and clamping bodies. The working principle of positioning and clamping is also the same. However, due to the particularity of the shape of the automobile welding structure itself, its welding clamp has the following characteristics.

1. The assembly and welding component of the automobile is a space surface structure with a complex shape, and most of them are composed of thin plate stamping parts (especially the body), which has small rigidity and is easy to deform. When welding, it must be positioned according to its shape, so the positioning components The layout also has the characteristics of spatial location. The positioning element is generally a positioning component composed of several parts.

2. There are many windows, openings and holes in automobile components, so these parts are often selected as the combined positioning surface

3. The production batch of automobiles is large, and the degree of decentralized assembly is high. In order to ensure interchangeability, it is required to ensure the consistency of the assembly and positioning references of the same component assembly, parts, and assembly, and to be as close as possible to the design reference (spatial coordinate grid line) coincide

4. Due to the high production efficiency of automobiles, quick clamps such as manual hinge-lever clamps, pneumatic clamps and pneumatic lever clamps are often used.

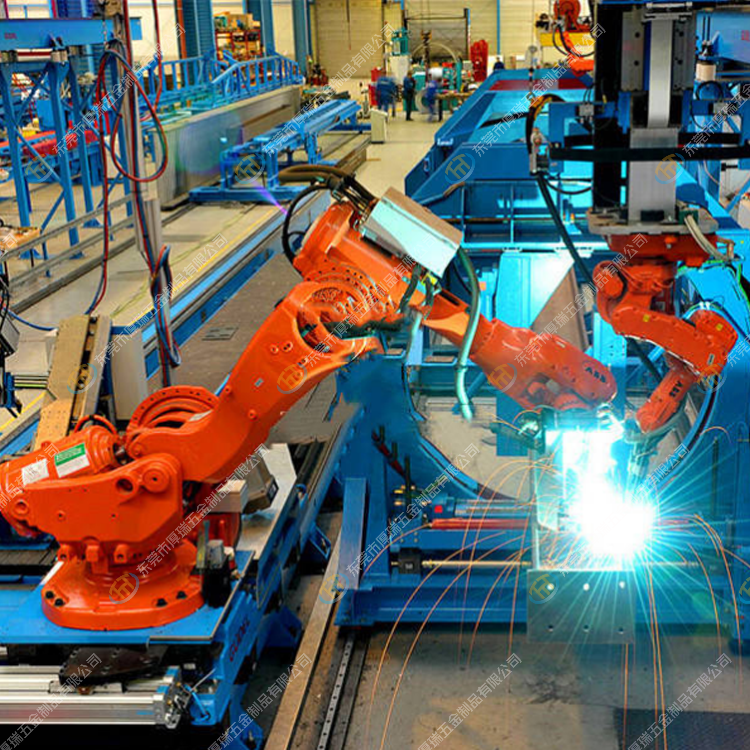

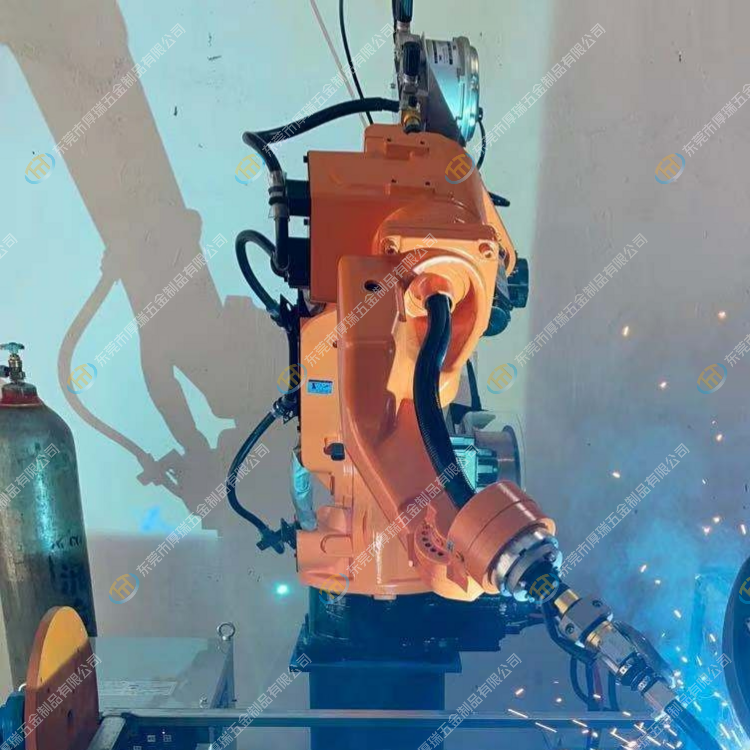

5. The automobile assembly and welding fixtures are mainly special fixtures, and the accompanying fixtures match the mechanized and highly automated automobile assembly and welding production lines.

6. Automobile body welding generally adopts resistance spot welding and CO2 gas shielded welding. The welding fixture should be compatible with the welding method to ensure the accessibility of welding and the openness of the fixture.

For some outer body panels with appearance requirements, the spot welding surface is not allowed to have depressions. When designing the product structure, it should be considered to complete the welding on a fixed spot welding machine. The required surface should be in contact with the lower electrode plane, or Single-sided double-spot welding is adopted. Some models even use hemming glue instead of spot welding on the hemming structure of the door, engine cover and luggage compartment cover to improve the appearance quality and corrosion resistance of the product.

Post time: Jun-02-2023

.png)

.png)