Automobile inspection tools are simple tools used by industrial production enterprises to control various sizes of products, such as apertures and space dimensions. It can improve production efficiency and control quality. It is suitable for mass-produced products. It replaces professional measurement tools in automotive parts, such as smooth plug gauges, threaded plug gauges, outer diameter gauges, etc. So what are the factors that need to be considered when designing automotive inspection fixtures?

Design and manufacture of automobile inspection fixtures. Before the design of inspection fixtures, the concept of the design of the inspection fixtures should be clarified. The main considerations are:

Fully understand GD & T, a descriptive document for automotive product design. Product specifications, product positioning benchmarks, key product characteristics, and product tolerance characteristics will be reflected on GD & T, so it must be fully understood before the design of the inspection fixture.

Determine the positioning and testing content of the product, analyze the benchmark characteristics of the product positioning, consider the optimal placement of product parts, understand the meaning of various tolerances, determine the testing content that product parts must implement on the inspection fixture and do not need to be achieved or even impossible What is implemented.

Statistics of process control capabilities, identifying whether the product has KPC requirements, CNC precision production to understand the purpose of the fixture, correctly understand the needs of quantitative measurement and qualitative measurement, and ensure the reliability of data collection.

Understand the requirements and processes, fully understand the customer's requirements for product inspection tools, learn from past success or failure cases, fully understand the customer inspection tool review and approval process, and understand the required documents.

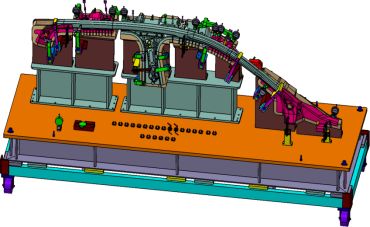

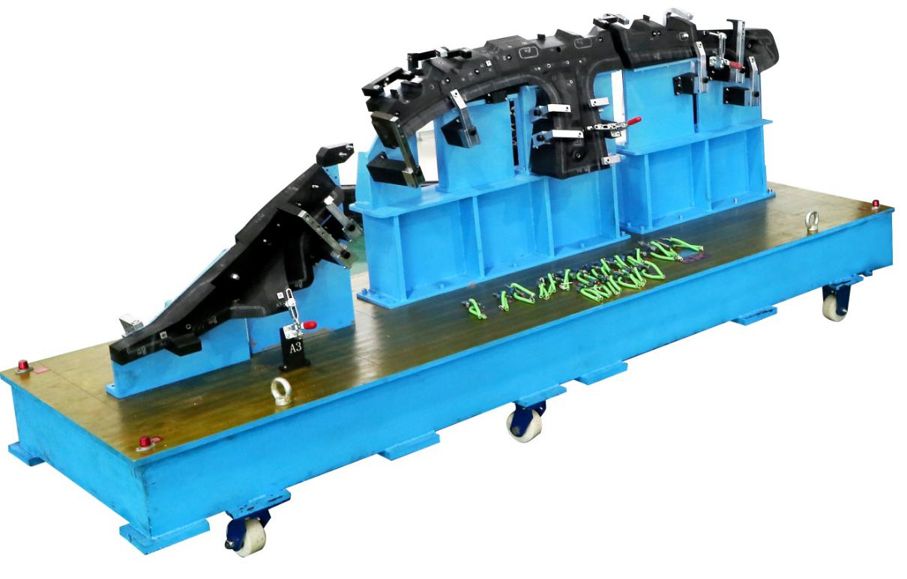

The design principle of the gage should have sufficient rigidity; it should have sufficient stability; it should have sufficient measurement accuracy to ensure the quality of the car; the operation should be convenient to ensure sufficient measurement efficiency; the structure should be as simple as possible to use; It has sufficient economic guarantee to facilitate the control of vehicle costs; at the same time, it should be easy to measure and calibrate. The design points should have the common characteristics of the auto parts inspection tool, and also have its own characteristics. Its structure is mainly composed of the following parts: base plate and frame part, positioning device, clamping device, measuring device, auxiliary device, etc.

Post time: Oct-26-2022

.png)

.png)