Cutting-Edge Digital Gauges Revolutionizing Automotive Assembly and Transform Manufacturing Precision

In a groundbreaking move, the automotive industry is witnessing a paradigm shift in manufacturing precision with the adoption of state-of-the-art digital gauges in assembly processes. This innovative technology is rapidly replacing traditional mechanical gauges, heralding a new era of efficiency, accuracy, and quality control in automotive part production.

Digital Gauges: Precision Redefined

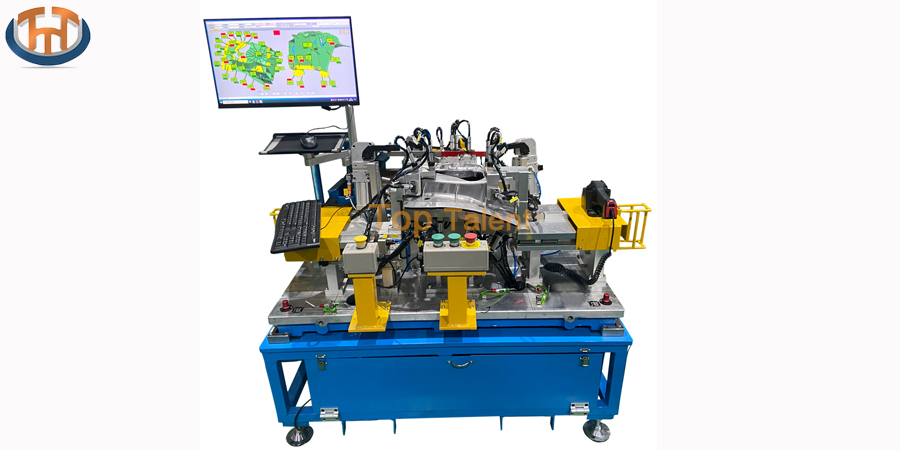

Digital gauges, equipped with advanced sensors and smart technology, are designed to provide unparalleled accuracy in measuring and inspecting components during the assembly process. Unlike their mechanical counterparts, these cutting-edge tools offer real-time data feedback, enabling manufacturers to achieve higher levels of precision and consistency in automotive part production.

Real-Time Monitoring for Enhanced Quality Control

One of the key advantages of digital gauges lies in their ability to facilitate real-time monitoring of assembly processes. With integrated sensors and connected systems, manufacturers can monitor critical parameters with unmatched precision. This real-time data allows for immediate identification of deviations or defects, enabling swift corrective actions to maintain the highest quality standards.

Efficiency Boost and Cost Savings

The implementation of digital gauges is not only improving the accuracy of measurements but is also contributing to significant efficiency gains in automotive part assembly. The streamlined data collection and analysis processes reduce the time required for quality checks, leading to faster production cycles. This increased efficiency not only results in cost savings but also allows manufacturers to meet growing demand with improved turnaround times.

Smart Integration with Industry 4.0

Digital gauges are a pivotal component of the Industry 4.0 revolution, where automation and smart technologies are integrated into the manufacturing ecosystem. These gauges seamlessly connect with other digital systems, forming a comprehensive network that optimizes the entire assembly line. The integration of Industry 4.0 principles allows for predictive maintenance, minimizing downtime, and optimizing overall production efficiency.

Customizable Solutions for Diverse Applications

Manufacturers across the automotive industry are benefiting from the versatility of digital gauges. These tools are customizable to suit the unique requirements of different assembly processes, accommodating a wide range of automotive parts and components. From engine components to electronic systems, digital gauges are proving to be adaptable solutions that cater to the diverse needs of the modern automotive manufacturing landscape.

Enhancing Worker Safety and Ergonomics

Digital gauges not only contribute to the precision of measurements but also prioritize the safety and well-being of assembly line workers. With ergonomic designs and user-friendly interfaces, these gauges are minimizing the physical strain on operators, contributing to a safer and more comfortable working environment. This focus on worker well-being aligns with the industry’s commitment to promoting a culture of safety on the factory floor.

Future Implications and Industry Adoption

As the automotive industry continues to embrace digital gauges, the implications for the future are profound. The ongoing shift towards smart manufacturing and the integration of digital technologies are expected to redefine industry standards and set new benchmarks for quality and efficiency. Manufacturers who invest in and adapt to these technological advancements are likely to gain a competitive edge in a rapidly evolving market.

In conclusion, the incorporation of digital gauges in automotive part assembly represents a transformative leap forward for the industry. The precision, efficiency, and real-time monitoring capabilities offered by these cutting-edge tools are reshaping the manufacturing landscape. As the automotive sector continues to evolve, digital gauges are emerging as indispensable tools that not only meet current demands but also pave the way for a future where innovation and efficiency go hand in hand.

Post time: Jan-26-2024

.png)

.png)