TTM Group is a company capable of manufacturing automotive automation welding equipment. Our products are widely used in the field of automobile manufacturing, and are deeply trusted and praised by customers. Our automotive automation welding products mainly include robotic welding systems, laser welding equipment, gas shielded welding equipment, etc. These products are all designed and produced by our professional team, featuring high efficiency, stability and safety.

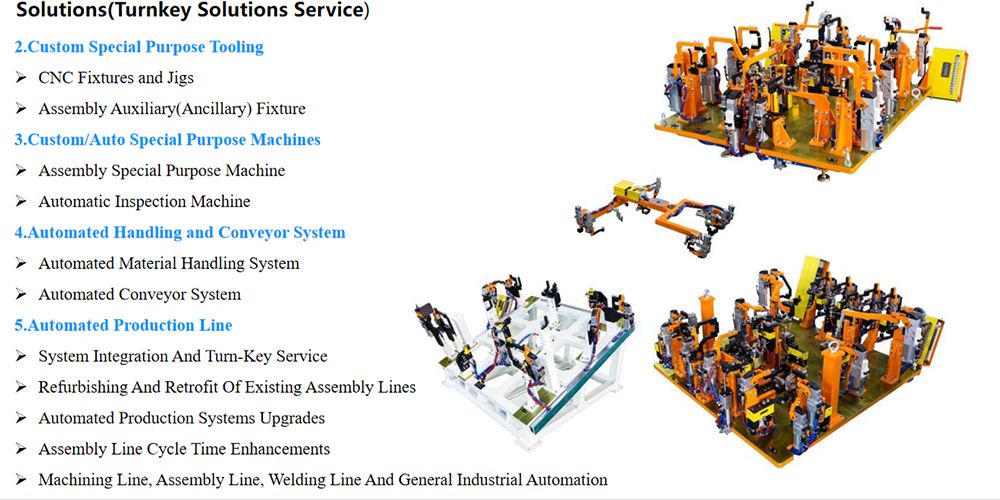

Since the structure of automobiles is more complicated than that of ordinary mechanical products, the assembly and welding process is difficult, and the production volume is large, especially the car body manufacturing has always been an industry with relatively concentrated high-tech applications. The key is mainly by large-scale welding robots and calculators. The body welding production line composed of advanced automatic coal loading equipment.

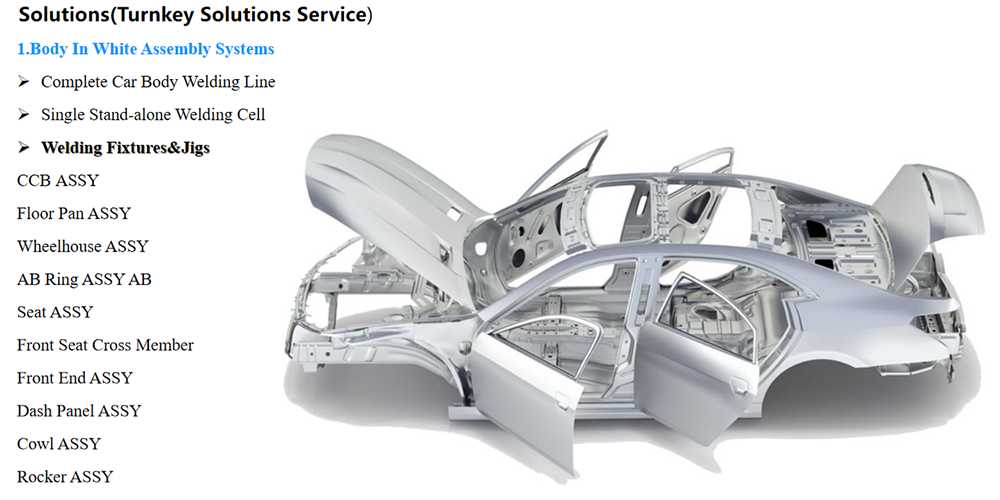

Most of the car body is composed of metal components and covering parts, and various pre-customized structural parts, such as windshield pillars, door pillars, door upper rails, front and rear fenders, front and rear panels, top covers, etc. Components are assembled by welding and riveting, among which welding is an indispensable step in the automobile assembly line.

In recent years, domestic large-scale car manufacturers have basically adopted welding robot body welding lines, and several of them have demonstrated the world’s leading technical strength. Among these robots, spot welding robots account for a relatively large proportion.

In recent years, the laser welding body technology has gradually replaced the resistance spot welding technology, which can basically meet the perfect requirements in the processing of auto parts. Using this new technology, the joint surface width between workpiece connections can be reduced, which not only reduces the demand for plates It also increases the rigidity of the body. Laser welding parts, there is basically no deformation in the welding parts of the parts, the welding speed is faster, and there is no need for post-weld heat treatment. Laser welding has good potential in terms of work efficiency, economy, safety, strength, and corrosion resistance. And this new technology has also become the mainstream machinery and equipment in the industrial manufacturing industry.

Our automotive automation welding products have been widely used in many automobile manufacturing enterprises to help customers realize production automation, improve production efficiency and quality, and create greater value for customers. We will continue to promote technological innovation and product research and development, provide customers with better products and services, and help the development of the automotive industry.

Post time: Apr-28-2023

.png)

.png)