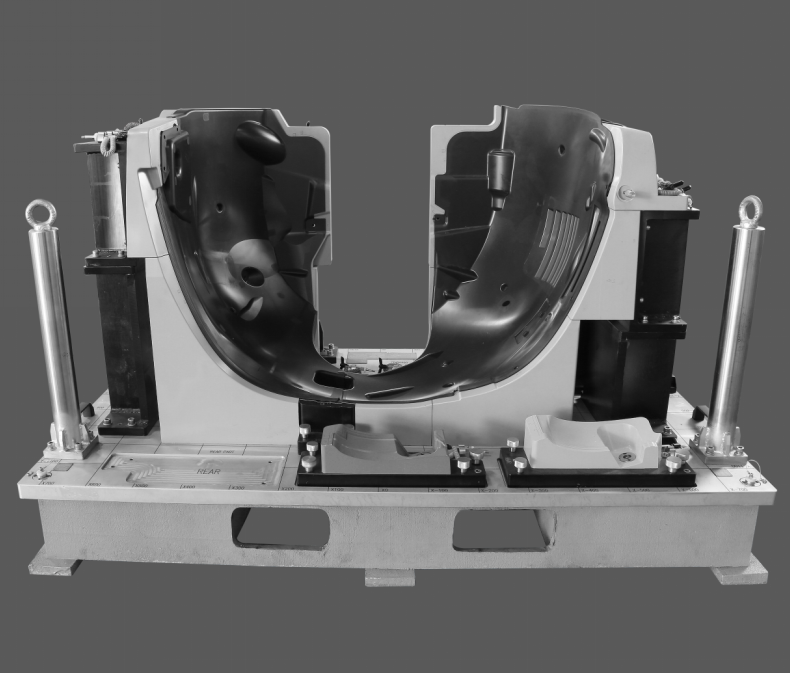

Check Fixture Design Company TTM Wheel House Liner Fixture Gauge

Video

Attributes

|

Size: |

1800*900*1500

|

|

parts: |

Wheel house liner |

|

Material |

Plastic |

|

Export Country : |

Germany |

|

Type: |

Plastic Part Checking Fixture Cases |

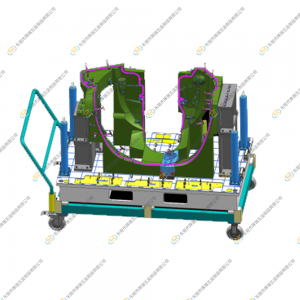

Product Pictures

Detailed Introduction

Introducing the Wheel House Liner Checking Fixture, a precision tool designed for use in automotive repair shops and manufacturing plants. This fixture is used to accurately measure and inspect the wheel housing liner, ensuring that it is properly positioned and securely mounted.

With this fixture, you can easily check the alignment of the liner, ensuring that it is correctly fitted and preventing damage to the vehicle's suspension and wheels. It also allows for quick and easy inspection of the liner's mounting points, helping to identify any issues or defects.

If you are looking for a reliable and accurate Wheel House Liner Checking Fixture, look no further than our product. It is a must-have tool for any mechanic or automotive professional who takes pride in their workmanship and wants to ensure that every repair job is done right.

The Working Flow

1. Received the purchasing order -——-> 2. Design -——-> 3. Confirming the drawing/solutions -——-> 4. Prepare the materials -——-> 5. CNC -——-> 6. CMM -——-> 6. Assembling -——-> 7. CMM-> 8. Inspection -——-> 9. (3rd part inspection if need) -——-> 10. (internal/customer on site) -——-> 11. Packing(wooden box) -——-> 12. Delivery

Manufacturing Tolerance

1. The Flatness of Base Plate 0.05/1000

2. The Thickness of Base Plate ±0.05mm

3. The Location Datum ±0.02mm

4. The Surface ±0.1mm

5. The Checking Pins and Holes ±0.05mm

.png)

.png)