Al / Steel Robotic Automation Systems Welding Fixture For Automotive Part

Video

|

Base Supporter: |

Steel |

Body Material: |

Al And Steel |

|

Template Material: |

Steel |

Weight: |

1035KG |

|

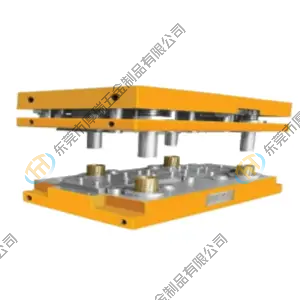

Size: |

1050*800*820mm |

Al And Steel Color: |

Oxidation Original Or Paint |

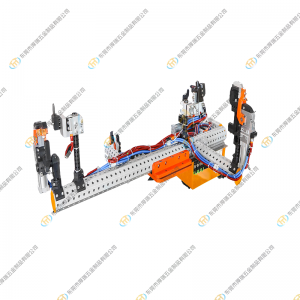

Automotive Part Customized Robot Automation Welding Jig Fixture

These two Inspection Fixtures have very complicated structure and consist of hundreds of components. Sliding units and blocks are wildly used used in these two Inspection Fixtures. Double guide rails and stoppers make the moving sliding units become stable.

We added stronger stopper to stop the sliding units in open direction and fixed pins in checking location.

To make it easier for operator to move this big Fixture, we make both lifting hook and universal wheels for these checking fixtures. To add the Fixtures strength, we adapt double welding plates and eight foot cups which will provide strong support. Operator can easily know the clamping sequence through small indemnification plates stamped beside the clamps.

Our production detail

| Items | ||

| 1 | Base Material | Al |

| 2 | Application | Stamping Parts |

| 3 | Surface treatment | Oxidation/Paint |

| 4 | Processing Precision | 0.15 |

| 5 | Accuracy for Other Profiles | 0.1 |

| 6 | Accuracy for Datum Hole | ±0.05 |

| 7 | Certificate | ISO 9001:2008 |

| 8 | CMM certification | Yes |

| 9 | Software | Catia, UG, CAD, STP |

| 10 | Specification | 1050*800*820mm |

| 11 | Packing | Wooden Box |

Color

Base Plate Surface: Original Color of Mental

Main Base Frame and Supports: Green Color

The Steel and Aluminum Parts: Black Anodized

Manufacturing tolerance

1.The Location Datum ±0.05mm

2.The Surface ±0.15mm

3.The Checking Pins and Holes ±0.1mm

Process

CNC Machining(Milling/Turning), Grinding

Black Anodized Treatment

Design Hours(h): 60h

Quality Control

CMM (3D Coordinate Measuring Machine), HR-150 A Hardness Tester

Lead time & Packing

2 months after 3D design approved

15 days via sea: HMM

Standard Export Wooden Case

Quality Policy

Legal Compliance

Customer First

Total Quality Control

System Operation

Continuous Improvement

We will adhere to the belief that TTM represents the highest quality and spare no effort to create a world-class quality enterprise.

More

Inspection Fixtures will be shipped with requisite operation instruction and CMM inspection report. Dust covers will be specially made for fixture protection.

.png)

.png)