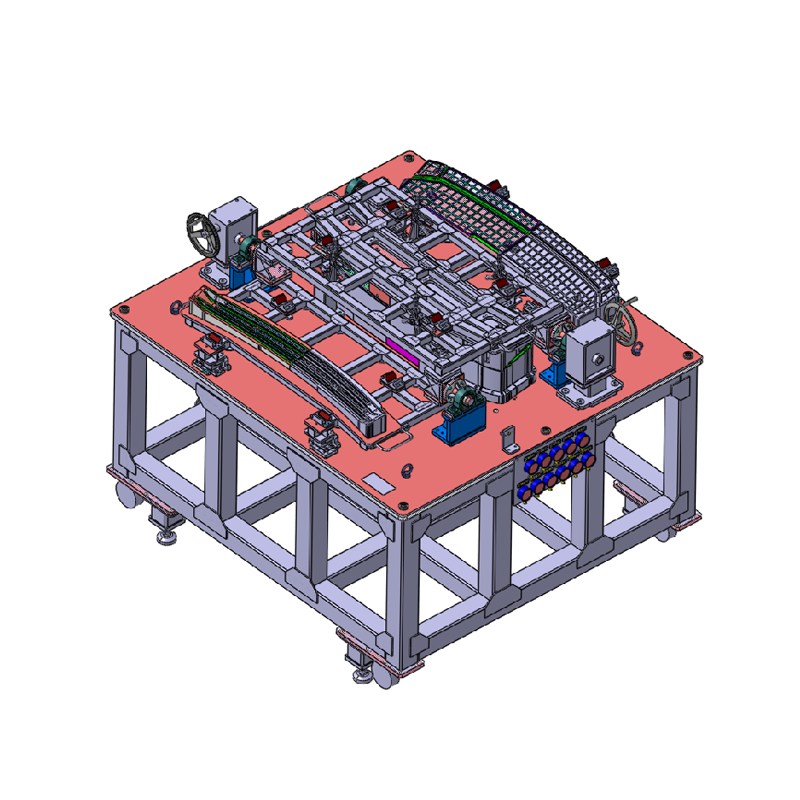

Well-designed Fabrication & Weldments - Top Beam Assembly Welding Fixture/A Beam Assembly Bonding Tooling – TTM

Well-designed Fabrication & Weldments - Top Beam Assembly Welding Fixture/A Beam Assembly Bonding Tooling – TTM Detail:

Function

For beam quality inspection control and support to improve the automotive production line capacity rate.

Specification

|

Fixture Type: |

Body In White Assembly Systems |

|

Size: |

1800x1300x900mm |

|

Weight: |

55KG |

|

Material: |

Main Construction: metal Support: metal |

|

Surface treatment: |

Base Plate: Electroplating Chromium and Black Anodized |

Product Details

Detailed Introduction

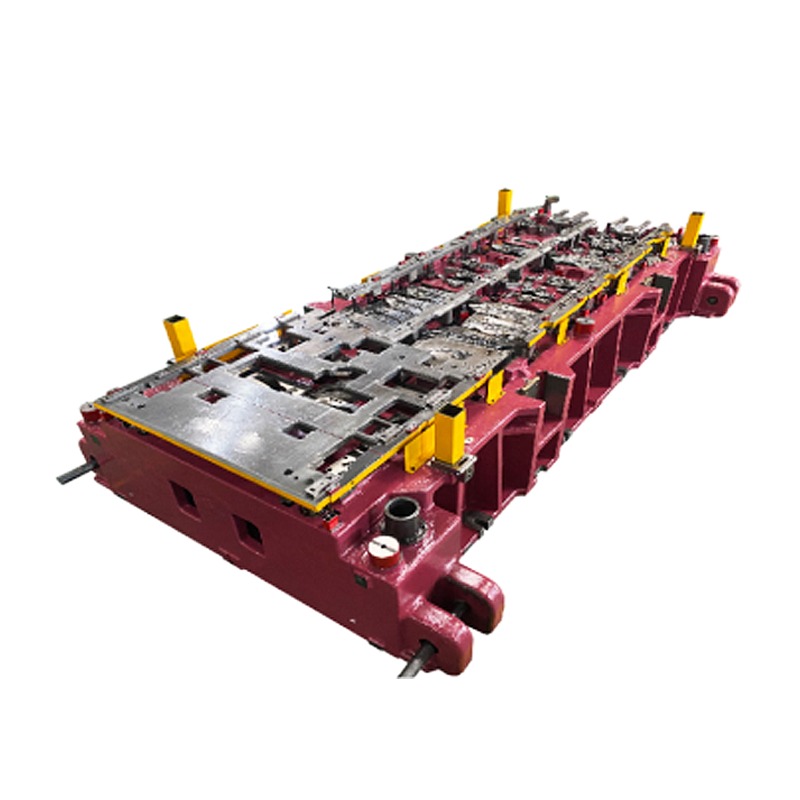

This is a batch of welding fixture of a beam assembly bonding tooling

, totally in 2 sets, we made for our Germany customer. Begin to design, customer came our factory confirm the designing with our design team together.In the process of design, we find that several sets of designs are similar. We offered our customer one set of design first. After receiving their feedback, we well know their specific requirements and preference and then we offer them the left designs. In this way, we reduced the design reviewing times, enhancing efficiency and shortening the delivery. And provide the optimal design plan and structure for customers.This car beam assembly fixture, adopting the technical proposal is: includes a support frame, supporting frame fixed clamp plate, HuoJu floor with beams bearing surface of subassembly and dowel, clamp plate of left and right sides is symmetrical with right and left active push board activities push board, left push board, right activities push board activities thrust plate on the fixture bottom rail guide: The positioning and pneumatic clamping device of the beam casting and the connecting bracket are set on the left movable push plate and the right movable push plate. By pneumatic control of the left movable push plate and the right movable push plate moving on the guide rail, the relative position of the beam casting, the connecting small bracket and the beam sub-assembly can be accurately realized, which facilitates the subsequent screw tightening process: The wood utility model realizes the positioning combination of beam casting and beam sub-assembly, ensuring the position degree, convenient assembly, high assembly efficiency, and reducing the labor intensity of workers.

The Working Flow

1. Received the purchasing order -——-> 2. Design -——-> 3. Confirming the drawing/solutions -——-> 4. Prepare the materials -——-> 5. CNC -——-> 6. CMM -——-> 6. Assembling -——-> 7. CMM-> 8. Inspection -——-> 9. (3rd part inspection if need) -——-> 10. (internal/customer on site) -——-> 11. Packing(wooden box) -——-> 12. Delivery

Lead time & Packing

45 days after 3D design approved

5 days via express: FedEx by Air

Standard Export Wooden Case

We will add fixing wooden block inside cases to make sure fixture safety in shipping. Desiccant and plastic wrap will be used to keep the checking fixture from moisture in shipping.

Product detail pictures:

Related Product Guide:

Our merchandise are commonly recognized and reliable by customers and can meet constantly developing economic and social desires for Well-designed Fabrication & Weldments - Top Beam Assembly Welding Fixture/A Beam Assembly Bonding Tooling – TTM , The product will supply to all over the world, such as: Jeddah, Ghana, Cannes, We adhere to the honest, efficient, practical win-win running mission and people-oriented business philosophy. Excellent quality, reasonable price and customer satisfaction are always pursued! If you are interested in our items, just try to contact us for more details!

The supplier cooperation attitude is very good, encountered various problems, always willing to cooperate with us, to us as the real God.

1.png)

.png)

.png)