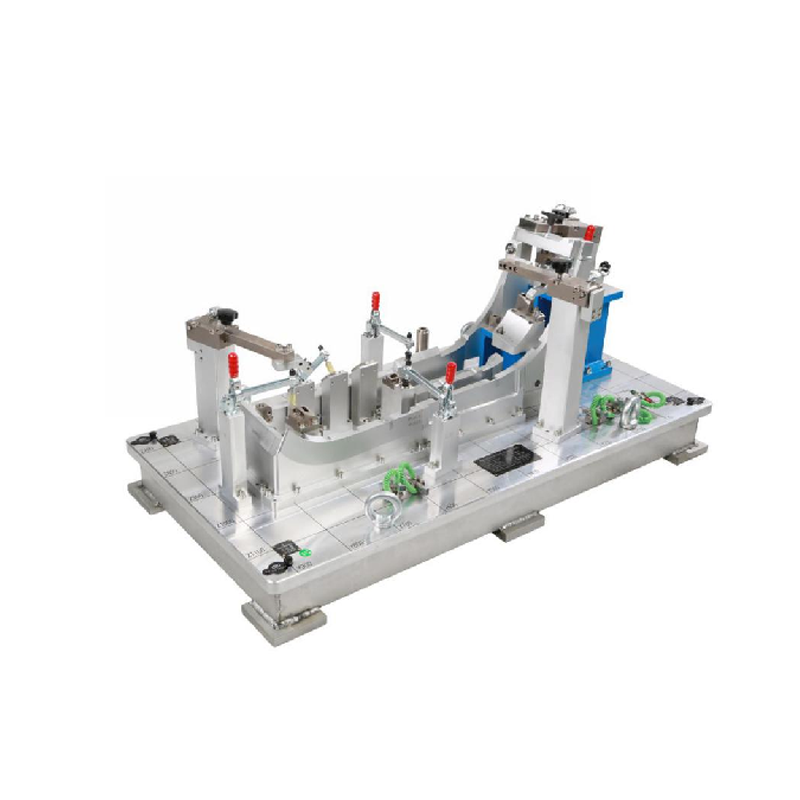

Professional Design Body In White Automotive - Door panel automotive inspection single metal plastic checking fixture design – TTM

Professional Design Body In White Automotive - Door panel automotive inspection single metal plastic checking fixture design – TTM Detail:

Specification

|

Fixture Type: |

Checking Fixture for Door Panel |

|

Size: |

2150*620*680 |

|

Weight: |

274KG |

|

Material: |

Main Construction: metal Support: metal |

|

Surface treatment: |

Base Plate: Electroplating Chromium and Black Anodized |

Product Details

Detailed Introduction

This is a auto parts checking fixture according to the parts testing requirements to design, precision machining.Plastic is a polymer material with resin as the main component. Resin is divided into natural and synthetic two categories, plastic synthetic resin, according to the use of plastic can be divided into general plastics, engineering plastics and special purpose plastics. Plastic instrument is rich in sources, low cost, and has the advantages of low density, high specific strength, good insulation performance, chemical stability, vibration reduction and wear resistance. Plastic has been widely used in modern industry and daily life, and its position in material forming engineering is becoming more and more important. Because the composition of plastic structure and performance and metal are different, so its forming method and mold and metal have very big difference. Furthermore, there are some differences between the inspection tools for plastic parts and those for metal parts. The inalienability of plastic determines its main molding methods, mainly injection (plastic) molding, extrusion molding, compression molding, injection molding, calendering and blow molding.Plastic forming is not the same as plastic forming. Sheet forming in plastic forming is commonly known as stamping. In automobile manufacture, steel plate stamping is a basic and extremely important process. Cold stamping die plays a key role in the quality of parts. Stamping is widely used in automobile main engine factories, plastic molding is widely used in parts factories:On the automobile, the parts covering the sheet metal parts of the body are collectively called inner and outer trim parts, which play a dual role of decoration and function. The manufacturing quality of automotive interior and exterior trim has a great influence on the quality of the vehicle, especially on the shape of the vehicle, so the inspection of its quality has become an essential work of the automobile factory. Much of the interior and exterior trim is plastic molding, such as the front and rear bumpers; Instrument panel: column interior and other easy to see, not easy to find plastic bracket: support; Cap; Small cover plate and trim plate and so on.

The Working Flow

1. Received the purchasing order -——-> 2. Design -——-> 3. Confirming the drawing/solutions -——-> 4. Prepare the materials -——-> 5. CNC -——-> 6. CMM -——-> 6. Assembling -——-> 7. CMM-> 8. Inspection -——-> 9. (3rd part inspection if need) -——-> 10. (internal/customer on site) -——-> 11. Packing(wooden box) -——-> 12. Delivery

Manufacturing Tolerance

1. The Flatness of Base Plate 0.05/1000

2. The Thickness of Base Plate ±0.05mm

3. The Location Datum ±0.02mm

4. The Surface ±0.1mm

5. The Checking Pins and Holes ±0.05mm

Product detail pictures:

Related Product Guide:

The shopper satisfaction is our primary focus on. We uphold a consistent level of professionalism, quality, credibility and repair for Professional Design Body In White Automotive - Door panel automotive inspection single metal plastic checking fixture design – TTM , The product will supply to all over the world, such as: Finland, Swiss, Namibia, Welcome to visit our company, factory and our showroom where displays various hair products that will meet your expectation. Meanwhile, it is convenient to visit our website, and our sales staff will try their best to provide you the best service. Please contact us if you need more information. Our aim is to help customers realize their goals. We are making great efforts to achieve this win-win situation.

Production management mechanism is completed, quality is guaranteed, high credibility and service let the cooperation is easy, perfect!

1.png)

.png)

.png)