In the hyper-competitive automotive world, where safety, aesthetics, and aerodynamics collide, few components are as critical – or as complex to manufacture – as the A-pillar. This structural element, framing your windshield and connecting the roof to the body, is vital for rollover protection and overall vehicle rigidity. But its complex curves, tight tolerances, and integration with glass, seals, and trim make consistent, high-quality production a monumental challenge. Enter the unsung hero of dimensional control: the A-Pillar Checking Fixture.

More Than Just a Template: The Fixture’s Critical Role

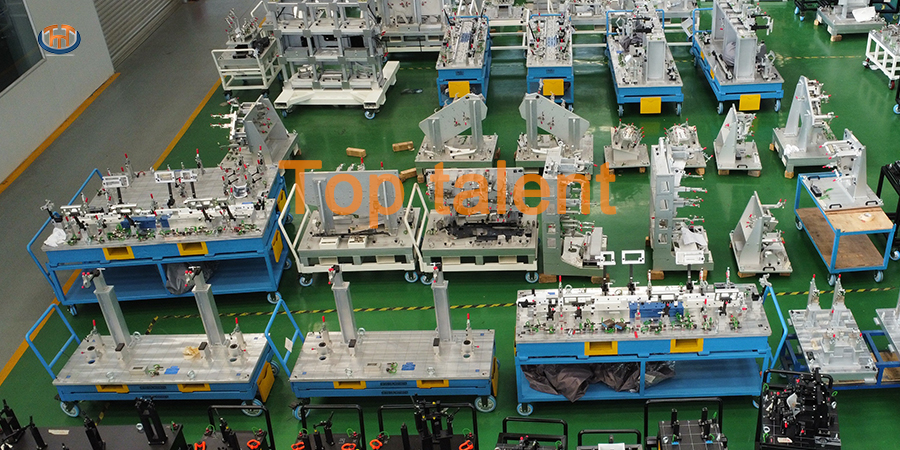

An A-Pillar checking fixture isn’t a simple jig. It’s a meticulously engineered master model, typically constructed from high-stability aluminum or composite materials. Its primary mission? To provide an absolute, unambiguous reference for verifying the dimensional accuracy of A-pillar parts before they hit the assembly line.

Here’s why these fixtures are indispensable:

Safety First: The A-pillar’s structural integrity is paramount. Even minor deviations can compromise its crashworthiness. Fixtures rigorously check critical mounting points, section thicknesses, and overall geometry against CAD data, ensuring every pillar meets stringent safety standards.

Perfect Fit & Finish: A-pillars directly interface with windshields, doors, roof panels, and weather seals. Gaps, misalignments, or poor flushness here scream poor quality. Checking fixtures validate the contours and interface points, guaranteeing seamless integration and a premium appearance.

Streamlining Assembly: An out-of-spec A-pillar can cause chaos on the assembly line, leading to rework, delays, and bottlenecks. Fixtures catch these defects early – at the supplier or incoming inspection – preventing costly line stoppages and ensuring smooth production flow.

Consistency Across Batches: Automotive production runs into the hundreds of thousands. Checking fixtures provide a consistent, repeatable standard against which every single A-pillar, from the first to the last, can be measured objectively. This is crucial for maintaining quality over time and across different production shifts.

Supplier Quality Control: For Tier 1 suppliers manufacturing A-pillars, checking fixtures are the agreed-upon “truth” with the OEM. They provide an indisputable method for proving conformance to specifications, building trust, and reducing disputes.

Key Design Considerations for Effective A-Pillar Fixtures:

Building an effective A-Pillar fixture requires deep expertise:

High Precision: Fixtures must be manufactured to tolerances significantly tighter than the parts they check (often sub-0.1mm).

Comprehensive Clamping: Securely locates the part in its true “as-installed” position without inducing distortion.

Critical Point Measurement: Features dedicated gauges (go/no-go pins, dial indicators, CMM targets) for key functional areas: hinge mounts, latch points, glass run channels, seal flanges, and critical contour sections.

Durability & Stability: Must resist wear and tear from constant use and maintain dimensional stability despite temperature variations in the factory.

Ergonomics & Accessibility: Designed for efficient use by quality personnel, allowing easy part loading/unloading and clear visibility of measurement points.

Data Capture: Increasingly integrate with digital tools (CMM arms, scanners) for automated data collection and analysis, feeding into SPC systems.

Beyond Compliance: The Business Impact

Investing in high-quality A-Pillar checking fixtures is not just about passing audits. It’s a strategic move:

Cost Reduction: Catches defects early, minimizing scrap, rework, warranty claims (especially related to wind noise or water leaks), and costly assembly line disruptions.

Speed to Market: Ensures parts are right the first time, preventing delays caused by dimensional issues surfacing late in production or during vehicle testing.

Enhanced Reputation: Delivers the consistent fit, finish, and safety that builds brand trust and customer loyalty.

Data-Driven Improvement: Fixture data pinpoints recurring manufacturing variations, enabling proactive process refinement at the supplier level.

The Bottom Line:

In the intricate ballet of automotive manufacturing, where precision is paramount and margins for error are vanishingly small, A-Pillar checking fixtures are the unwavering guardians of quality. They are the physical manifestation of design intent, ensuring that every vehicle rolling off the line possesses the structural soundness, aesthetic perfection, and reliable performance that modern drivers demand. For any OEM or supplier serious about excellence in body construction, robust A-Pillar checking fixtures are not just a tool – they are a fundamental necessity.

Post time: Jun-21-2025

.png)

.png)