Introduction

Metal stamping is a cornerstone of modern manufacturing, forming everything from tiny electronic components to large automotive body panels. But at the heart of every stamped metal part is a precision-engineered tool: the stamping die. The type of die used directly impacts a part’s complexity, cost, and production speed.

If you’re sourcing stamped parts or simply curious about the process, understanding the different types of metal stamping dies is crucial. This guide breaks down the three primary categories—progressive, transfer, and compound dies—to help you make an informed decision.

1. The Progressive Die: High-Speed Efficiency

A progressive die is the workhorse of high-volume production. Imagine a single, complex die with multiple stations. A strip of metal, called a coil, feeds through the die. At each station, a different operation is performed—such as punching, bending, or notching. The part, still attached to the metal strip, moves from one station to the next until a finished part is ejected at the final station.

Key Advantages:

High Speed: Capable of producing hundreds of parts per minute.

Efficiency: Multiple operations are completed in a single press stroke, minimizing handling.

Cost-Effective: Ideal for large production runs where the initial tooling cost is justified.

Common Applications: Electrical connectors, bracket components, and appliance parts.

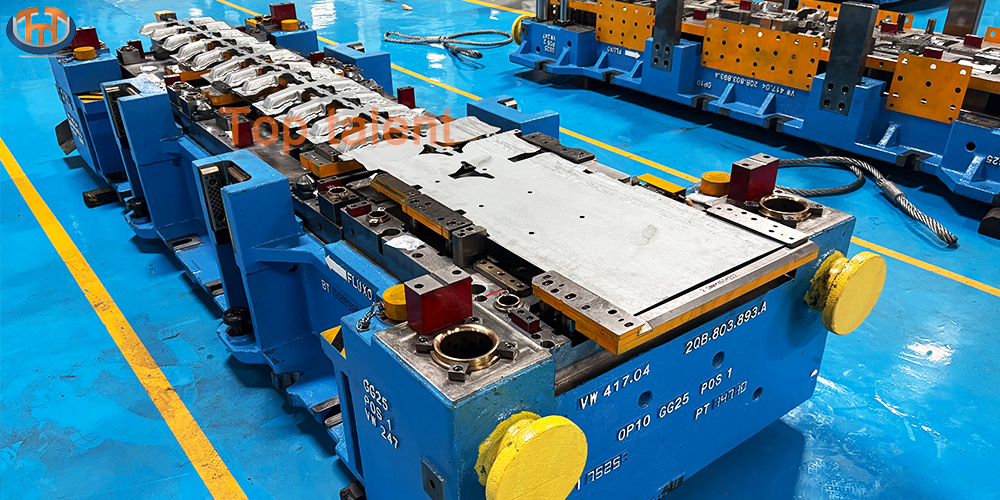

2. The Transfer Die: For Larger, Complex Parts

While a progressive die works on a connected strip of metal, a transfer die handles individual parts. The metal blank is cut in the first station. Then, mechanical fingers or a robotic transfer system pick up the part and move it through a series of separate dies, each performing a specific operation. This system is like an assembly line within a single press.

Key Advantages:

Handles Large Parts: Suitable for components like automotive door frames or appliance cabinets that are too big for a progressive strip.

Greater Flexibility: Allows for more complex, multi-sided forming operations.

No Carrier Strip: Eliminates the scrap material left over from the strip in progressive stamping.

Common Applications: Automotive body panels, sinks, and other large, deep-drawn components.

3. The Compound Die: Simplicity and Precision in a Single Stroke

For simpler parts requiring high precision, the compound die excels. This die performs multiple cutting operations—such as blanking and piercing—in a single press stroke. Unlike progressive dies, a compound die produces a finished part in one station, with no in-progress movement.

Key Advantages:

Excellent Precision: Because all operations happen in one stroke, alignment is extremely accurate.

Simplicity: Less complex and often lower in cost to build than progressive or transfer dies.

High-Quality Edges: Ideal for parts where the edge quality of the blank is critical.

Common Applications: Flat, washer-like parts, electrical contacts, and any component requiring a cleanly blanked edge in high volumes.

Choosing the Right Die for Your Project

Selecting the optimal die type is a balance of part design, volume, and budget.

Choose a Progressive Die for high-volume, smaller parts where speed is paramount.

Opt for a Transfer Die for larger, more complex parts that require deep draws or multi-sided forming.

Select a Compound Die for simpler, high-precision flat parts produced in significant quantities.

Conclusion

The art of metal stamping relies on the science of its tooling. Whether it’s the rapid-fire efficiency of a progressive die, the flexible handling of a transfer system, or the singular precision of a compound die, each type offers unique benefits. By partnering with a knowledgeable metal stamping provider who understands these distinctions, you can ensure your project is manufactured with the most efficient, cost-effective, and high-quality process possible.

Post time: Nov-11-2025

.png)

.png)