When you pop the trunk to load groceries or luggage, you’re likely focused on the space, not the panel itself. But that seamless, perfectly fitting trunk lid is a minor miracle of modern manufacturing. Its journey from a flat sheet of steel to a complex, high-strength automotive component begins with one of the most impressive pieces of engineering in the industry: the automotive trunk lid metal stamping tool.

What is a Trunk Lid Stamping Tool?

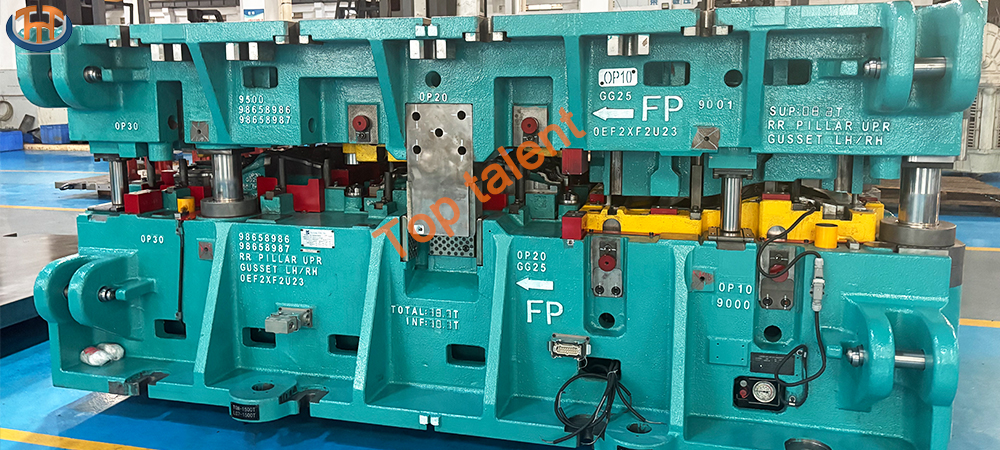

In simple terms, a stamping tool (or die) is a massive, precision-made mold for metal. For a part as large and intricate as a trunk lid, this isn’t a single tool but a progressive die system housed within a powerful stamping press. A coil of sheet metal, often a advanced high-strength steel or aluminum alloy, is fed through this system.

At each station, the tool performs a specific action, progressively transforming the blank metal. These stages typically include:

Blanking: Piercing the initial outline of the trunk lid from the larger steel coil.

Drawing: The most critical step. Here, the blank is stretched and formed over a die into its fundamental three-dimensional shape with all the major contours.

Trimming: Cutting away the excess “flash” metal from the drawn shape.

Piercing: Creating precise holes for features like lock mechanisms, license plate lights, and hinge mounting points.

Flanging: Bending the edges to create a strong, rigid seam for welding and to provide a surface for seal attachment.

The Engineering Challenges of a Perfect Fit

Designing and building a trunk lid stamping tool is a monumental task. The challenges are immense:

Dimensional Perfection: A trunk lid must align perfectly with the rear quarter panels and bumper, with uniform gaps that are mere millimeters wide. Any slight imperfection in the tool translates to a visible flaw on the final vehicle.

Eliminating Springback: Metal has memory. After being stamped, it naturally tries to spring back to its original flat shape. Tool designers must use advanced simulation software to predict and counteract this springback, shaping the tool beyond the desired final form so the metal springs back to the perfect contour.

Surface Quality: The tool’s surface must be flawlessly polished. Any minor scratch or imperfection on the die will be replicated onto every single trunk lid it produces, ruining the paint-ready surface.

Durability and Maintenance: These tools are built to withstand millions of cycles under immense pressure—often thousands of tons. They are typically machined from solid blocks of tool steel and require meticulous maintenance to prevent wear and ensure consistent quality over their long lifespan.

Beyond the Metal: The Impact on Vehicle Quality

The quality of the stamping tool directly impacts the vehicle’s final quality, safety, and performance. A precisely stamped trunk lid ensures:

Aerodynamic Efficiency: A flush fit contributes to lower wind noise and better fuel economy.

Weatherproofing: Accurate flanges allow for a perfect seal, keeping water and dust out of the trunk.

Structural Integrity: The formed contours and ribs add significant stiffness, contributing to the vehicle’s overall torsional rigidity and crash safety.

Conclusion

The next time you close your car’s trunk with a satisfying, solid thud, take a moment to appreciate the unseen marvel that made it possible. The trunk lid stamping tool is a masterpiece of precision engineering, a testament to the incredible innovation that drives the automotive world forward. It’s not just shaping metal; it’s shaping the quality, safety, and aesthetic of every vehicle on the road.

Post time: Nov-07-2025

.png)

.png)