In the high-precision world of automotive manufacturing, where millimeter tolerances define quality and safety, the welding fixture is an unsung hero of the production line. Specifically, the Cowl Front Welding Fixture is a cornerstone of vehicle body-in-white (BIW) assembly, playing a pivotal role in determining a car’s structural integrity, aesthetics, and performance. For industry professionals and enthusiasts seeking to understand the backbone of auto manufacturing, this component is where engineering excellence begins.

What is a Cowl Front Welding Fixture?

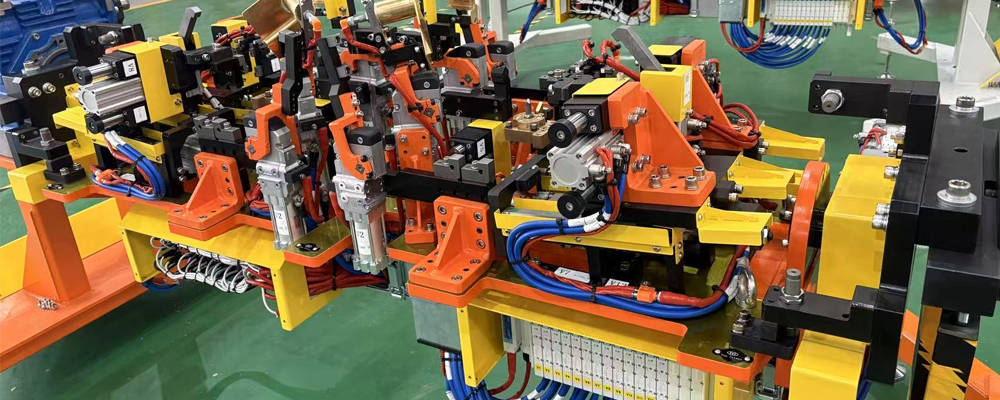

The cowl front, or dash panel, is the critical structural component that separates the engine compartment from the passenger cabin. It serves as the foundation for the dashboard, steering column, pedal assembly, and HVAC systems, while also contributing to crash safety and vehicle rigidity. A cowl front welding fixture is a custom-designed, rigid apparatus that precisely locates and clamps the various sheet metal panels of the cowl front assembly—often including the cowl top panel, dash panel, hinge pillars, and plenum panels—in their exact design positions for robotic or manual welding.

Why It’s a Linchpin of Quality and Efficiency

1. Precision and Repeatability: In an era of modular platforms and global production, consistency is king. A superior fixture ensures that every vehicle, whether built in Detroit or Delhi, has a cowl front welded with identical geometry. This repeatability is vital for proper fitment of windshield, doors, and front-end modules, preventing costly rework and warranty issues.

2. Structural Integrity & Safety: The cowl area is a key node in the vehicle’s safety cell. Accurate welding, guaranteed by a well-engineered fixture, ensures optimal load paths during a collision. Even minor misalignment can compromise crash performance and NVH (Noise, Vibration, and Harshness) characteristics.

3. Adaptability for Modern Lines: Today’s fixtures are marvels of flexible manufacturing. With the rise of electric vehicles and multi-model production lines, modern cowl fixtures often incorporate programmable logic controllers (PLCs), auto-locking pins, and quick-change modules. This allows a single fixture to accurately assemble different cowl designs for various models, maximizing ROI and production agility.

4. Enabling Automation: Robust, fool-proof fixtures are the enablers of automated welding cells. They provide the consistent reference points robots need to perform hundreds of perfect welds, cycle after cycle, driving up throughput and eliminating human error in precise positioning.

Innovation in Fixture Design

The future of cowl front fixtures lies in smart tooling. Integrated laser scanners and sensors now provide real-time measurement and data feedback, creating a closed-loop quality system. This “Industry 4.0″ approach allows for predictive maintenance and immediate correction of any drift from tolerance, pushing quality control from inspection to prevention.

Furthermore, the use of advanced, lightweight composites for fixture bodies reduces wear and tear on robotic arms and improves energy efficiency on the line.

Conclusion

While it may never capture the spotlight, the cowl front welding fixture is a foundational technology in automotive manufacturing. It is where a vehicle’s blueprint first becomes tangible steel. Investing in its precision, durability, and intelligence directly translates to vehicles that are safer, better built, and more cost-effective to produce. For automakers competing on the global stage, excellence in this unseen arena is not just an engineering detail—it’s a strategic imperative.

Post time: Jan-24-2026

.png)

.png)