The automotive industry relies heavily on precision-engineered components to ensure vehicle safety, durability, and performance. Among these, the cross-car beam stands out as a critical structural element. Acting as a backbone within the dashboard, cross-car beams enhance crash protection, reduce vibration, and support airbag systems. Manufacturing these components demands advanced technology, particularly through automotive cross-car beam stamping dies—a process combining innovation and engineering excellence.

The Role of Stamping Dies in Cross-Car Beam Production

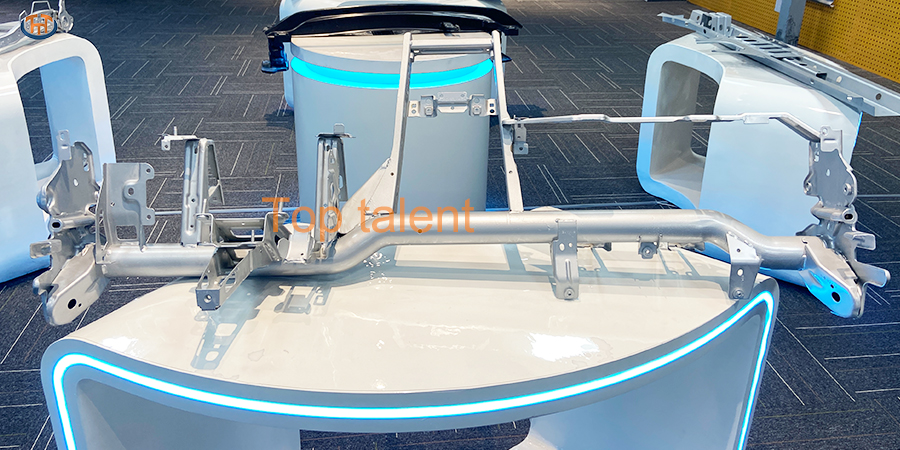

Stamping die manufacturing is pivotal for shaping high-strength materials into complex geometries. Cross-car beams require exact specifications to meet strict safety standards, making precision stamping dies indispensable. These dies, often crafted from hardened tool steel, use high-pressure stamping presses to transform blanks of steel or aluminum into rigid beams. With electric vehicles (EVs) and lightweighting trends on the rise, stamping dies must now accommodate materials like ultra-high-strength steel (UHSS) and advanced aluminum alloys, balancing strength with weight reduction.

Materials and Design: Balancing Strength and Efficiency

Modern cross-car beams prioritize high-strength steel stamping to withstand collision forces while minimizing weight. Stamping dies are designed to handle these materials without compromising structural integrity. Engineers use CAD/CAM software and finite element analysis (FEA) to simulate stamping processes, ensuring dies produce defect-free components. Custom stamping dies are increasingly popular, allowing automakers to tailor beams for specific models, enhancing compatibility with ADAS sensors or EV battery mounts.

Precision and Quality Control in Die Manufacturing

Quality assurance is non-negotiable. Automotive manufacturing efficiency hinges on dies that maintain tolerances within microns. Advanced inspection tools like 3D laser scanning and coordinate measuring machines (CMM) verify each die’s accuracy. Manufacturers adhering to IATF 16949 and ISO standards ensure consistency, reducing recalls and boosting consumer trust.

Technological Advancements Driving the Industry

Innovation in stamping die technology is accelerating. AI-driven predictive maintenance minimizes downtime by anticipating tool wear, while servo-driven presses offer unmatched control over stamping speed and force. Additive manufacturing also plays a role, enabling rapid prototyping of die components. These advancements reduce production cycles, helping automakers meet tight deadlines without sacrificing quality.

Benefits to the Automotive Sector

Investing in advanced stamping dies translates to long-term gains. High-speed production lines equipped with durable dies lower per-unit costs, while lightweight beams improve fuel efficiency—a key selling point for EVs. Enhanced crash protection components also elevate safety ratings, strengthening brand reputation.

The Future of Stamping Dies

As sustainability becomes a priority, stamping die manufacturers are exploring eco-friendly practices, such as recycling tool materials and optimizing energy use. The shift toward autonomous vehicles will further drive demand for beams with integrated sensor mounts, requiring even more specialized dies.

Conclusion

Automotive cross-car beam stamping dies are unsung heroes in vehicle manufacturing, merging precision, innovation, and safety. As the industry evolves, advancements in materials, simulation software, and automation will keep these dies at the forefront of automotive engineering. For automakers, partnering with experts in custom stamping dies ensures they stay competitive in an era where safety, efficiency, and sustainability are paramount.

Post time: May-16-2025

.png)

.png)