In the high-stakes world of automotive manufacturing, where precision is measured in microns and safety is paramount, one tool plays a critical yet often overlooked role: the automotive seat checking fixture. This specialized device is the silent guardian of comfort, safety, and quality, ensuring that every seat installed in a vehicle meets exacting design specifications before mass production begins.

What is an Automotive Seat Checking Fixture?

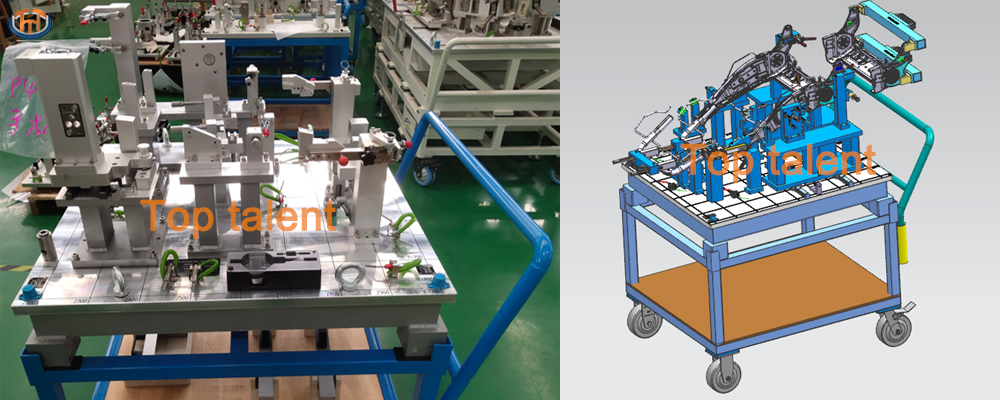

A checking fixture, or C/F, is a custom-built, physical validation tool designed to verify the dimensional accuracy of an automotive component—in this case, a vehicle seat. It is a tangible, full-scale replica of the critical interface points within the car’s cabin, built from durable materials like aluminum and steel. Its primary function is not to assemble the seat, but to measure and validate its key characteristics: the location of mounting holes, the contour of the seat frame, the positioning of belt guides, and the spatial relationship to adjacent components like the centre console or B-pillar.

Why is this Fixture Indispensable?

Long before a seat reaches the assembly line, its design undergoes a rigorous transition from digital CAD models to physical prototypes. The checking fixture acts as the crucial bridge in this process.

Quality Control & Validation: It is the definitive “go/no-go” gauge for production-ready seat assemblies. Manufacturers use CMM (Coordinate Measuring Machine) arms and other probes directly on the fixture to collect precise data, confirming the seat is built correctly and will fit perfectly in the vehicle.

Saving Time and Cost: Identifying a dimensional flaw in a seat design on the fixture, before hard tooling is cut, prevents catastrophic downstream expenses. It avoids production delays, costly retooling, and potential vehicle recalls due to fitment or safety issues.

Ensuring Safety and Compliance: Correct seat positioning is vital for the proper function of seatbelts and airbags. A fixture verifies that attachment points for these critical safety systems are in the exact specified location, directly supporting compliance with stringent global safety standards.

Supplier Accountability: For automakers who source seats from tier-one suppliers, the checking fixture serves as an objective, shared standard. Both parties use the same master tool to validate parts, ensuring consistency and eliminating disputes over measurement criteria.

The Fixture as a Cornerstone of Excellence

In an era of increasing vehicle automation and sophisticated occupant safety systems, the role of the seat is evolving. It’s no longer just a place to sit; it’s an integrated component of the vehicle’s safety cell and comfort ecosystem. Modern checking fixtures are now also used to validate the integration of heated/cooled elements, embedded sensors, power adjustment mechanisms, and side-airbag deployments.

While the final customer will never see or directly interact with a seat checking fixture, its impact is felt with every comfortable, secure, and perfectly aligned drive. It embodies the principle of “measure twice, cut once” on an industrial scale. For automotive engineers and quality managers, it is an indispensable investment in precision, a fundamental tool that safeguards brand reputation by ensuring that one of the most intimately connected parts of the car—the seat—is flawless from the very first unit to the millionth. In the relentless pursuit of automotive quality, the checking fixture remains an unsung hero, proving that true excellence is always in the details.

Post time: Dec-05-2025

.png)

.png)