In the world of automotive manufacturing, the spotlight often shines on the six-axis robots performing intricate welds with superhuman speed and precision. But what if the true secret to their flawless performance isn’t the robot itself, but the often-overlooked technology holding the product in place? Enter the robotic arc welding fixture: the critical, unsung hero that makes modern auto assembly possible.

What Exactly is a Robotic Welding Fixture?

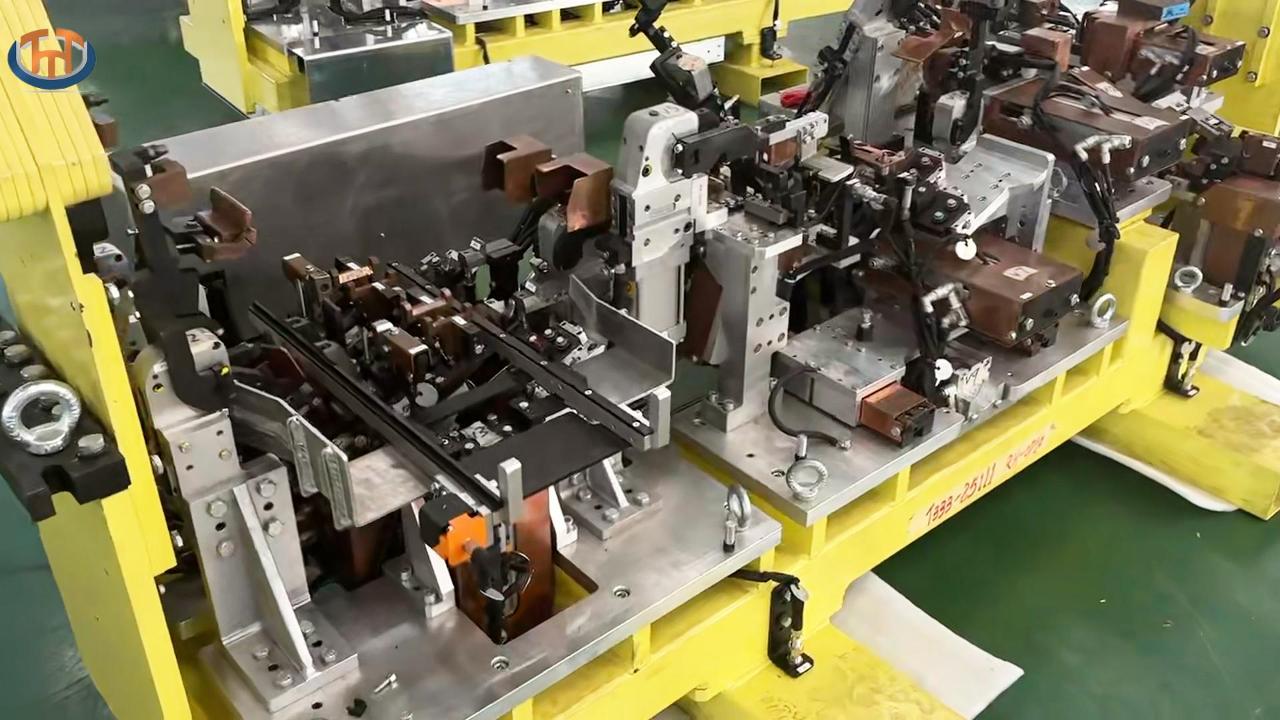

A robotic welding fixture is a custom-designed clamping device that securely holds multiple vehicle components in perfect alignment during the welding process. Think of it as a sophisticated, ultra-precise jig. For a car chassis or subframe, this means holding dozens of individual stamped metal parts in their exact designated positions, with zero room for error, before the robot even makes its first pass.

The Critical Role of Fixtures in Automotive Robotics

Why are these fixtures so indispensable? The answer lies in the unforgiving nature of automation.

Absolute Precision and Repeatability: A robot will weld exactly where it is programmed to weld. If a part is misaligned by even a millimeter, the weld will be defective, leading to a weak joint or a costly rework. Fixtures eliminate this variable, ensuring that every single unit presented to the robot is identical to the last. This repeatability is the bedrock of mass production.

Enabling Automation and Speed: Without a fixture to present the entire assembly at once, robots would be limited to welding single components in sequence, drastically slowing down production. Advanced fixtures allow for “load while weld” operations, where an operator loads new parts into one side of a fixture while the robot is simultaneously welding a completed assembly on the other. This parallel process maximizes uptime and throughput.

Reducing Variability and Scrap: Human welders can adapt to minor inconsistencies in part fit-up. A robot cannot. Fixtures compensate for inherent slight variations in stamped components by forcefully clamping them into their nominal, perfect position. This drastically reduces part-to-part variability, minimizes scrap rates, and ensures every vehicle structure meets stringent safety and quality standards.

Key Innovations in Modern Welding Fixtures

The humble fixture has evolved significantly alongside robotics:

Modular and Flexible Designs: To accommodate the industry’s shift towards multi-vehicle platforms, manufacturers now use modular fixtures with interchangeable components. This allows one fixture base to be quickly reconfigured for different car models, saving massive costs and factory floor space.

Integrated Clamping with Robot Control: Modern fixtures are often directly integrated with the robot controller. The clamping sequence is part of the automated workflow—the robot will not begin its cycle until the fixture confirms all clamps are secure and part presence sensors are activated, adding a crucial layer of process control.

Lightweighting and Durability: Using materials like high-strength aluminum and composite plastics, engineers create fixtures that are lighter (reducing wear on positioners) yet incredibly rigid and durable to withstand the harsh environment of a welding cell.

The Bottom Line

While the robot is the star performer, the welding fixture is the director ensuring the show goes on without a hitch. It is a fundamental pillar of quality, efficiency, and scalability in automotive manufacturing. Investing in well-designed, robust robotic welding fixtures isn’t just an equipment purchase; it’s an investment in the integrity of the vehicle and the profitability of the entire production line. As the automotive industry continues to innovate with new materials and electric vehicle platforms, the precision demanded from these foundational tools will only become more critical.

Post time: Sep-20-2025

.png)

.png)