Discover how automotive assembly checking fixtures ensure precision, reduce costs, and maintain quality in vehicle manufacturing. Learn about their types and critical role in production.

In the high-stakes world of automotive manufacturing, precision is non-negotiable. A misaligned panel, a poorly seated component, or a faulty bracket can lead to everything from annoying rattles to critical safety issues. While robotics and advanced machinery capture the spotlight, there’s a humble, yet indispensable, tool working behind the scenes to guarantee perfection: the automotive assembly checking fixture.

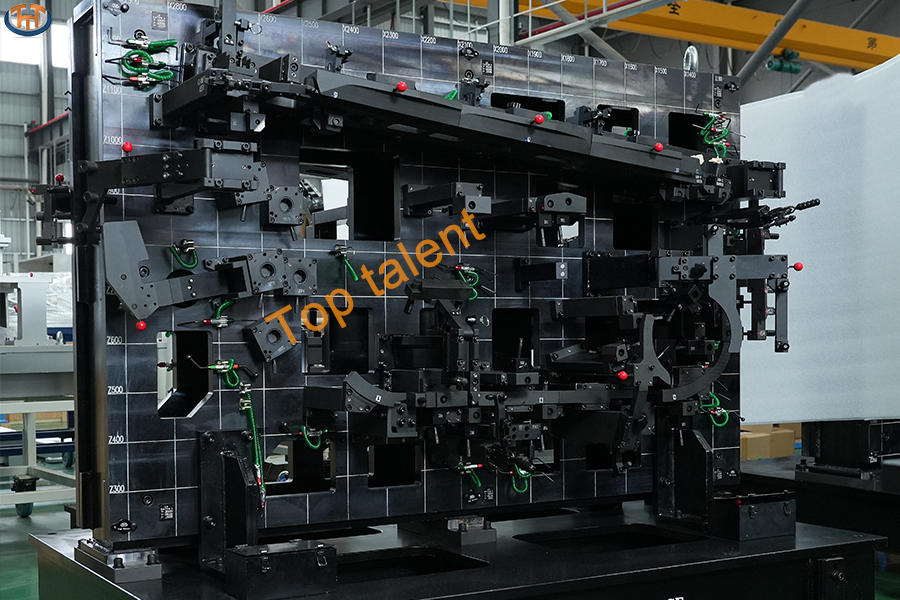

What is an Automotive Checking Fixture?

A checking fixture (or C/F) is a custom-built, physical gauge designed to verify the dimensional accuracy of a vehicle part or sub-assembly. Think of it as a high-precision, reverse 3D puzzle. Instead of building a part, the fixture is built to hold the part perfectly. By placing a newly manufactured component—a fender, bumper, or even a complex chassis bracket—into the fixture, quality engineers can quickly and accurately determine if it meets all design specifications.

Why Are Checking Fixtures Critical for Auto Manufacturers?

The value of these tools extends far beyond simple measurement.

Ensuring Dimensional Accuracy: They are the first and last line of defense against dimensional defects. By physically replicating the mating surfaces and critical datums (reference points) of a vehicle’s design, they confirm that every part will fit perfectly on the assembly line, preventing costly bottlenecks.

Driving Cost-Efficiency: Catching a defect early with a checking fixture saves immense costs. It prevents the mass production of out-of-spec parts, avoids line stoppages, and eliminates the massive expense of warranty claims and recalls down the road. They are a proactive investment in quality.

Enabling Rapid Validation: During the critical launch phase of a new vehicle, checking fixtures are used to validate parts from suppliers before full-scale production begins. This allows for swift feedback and corrections, drastically reducing time-to-market.

Supporting Root Cause Analysis: When a fit or finish issue arises, checking fixtures are used to isolate the problem. Is it the door itself, or the hinge? By testing each component in its dedicated fixture, engineers can quickly identify the source of the error.

Types of Automotive Checking Fixtures

The complexity of a fixture mirrors the complexity of the part it checks:

Master Fixtures: Used to check the accuracy of other, simpler fixtures or for calibrating measurement systems.

Sub-Assembly Fixtures: Designed to check how multiple components fit together, like a complete door module with its internal mechanisms.

Individual Part Fixtures: The most common type, built for a single specific component like a hood, headlamp, or console.

Functional Checking Fixtures: These go beyond simple dimensions to verify aspects like the smooth operation of a glove box latch or the correct deployment of a airbag cover.

The Digital Shift: From Physical to Virtual

The industry is evolving with the adoption of Digital Checking Fixtures. Using 3D CAD models and software like CATIA or Siemens NX, engineers can now simulate how a part will fit within a virtual assembly before a single physical tool is built. This digital validation further streamlines development, identifies potential issues earlier, and optimizes the design of the physical fixtures themselves.

Conclusion: An Investment in Excellence

While they may not be as glamorous as a new robotic arm, automotive assembly checking fixtures are fundamental to the quality, safety, and reliability of every vehicle on the road. They are a tangible commitment to excellence, ensuring that the millions of parts that make up a car come together in perfect harmony. In an industry where margins are thin and reputation is everything, the checking fixture remains an unsung hero of modern manufacturing.

Post time: Sep-06-2025

.png)

.png)