In the high-stakes world of automotive manufacturing, perfection is not just a goal—it’s a requirement. Every component, from the engine block to the smallest trim piece, must meet exacting standards. For closure panels like the trunk lid (or boot lid), this final validation often rests on a critical, yet often overlooked, piece of tooling: the Trunk Lid Final Checking Fixture.

While CAD models and digital scans are indispensable, the physical checking fixture remains the tangible, undeniable “source of truth” on the production floor. It is the final arbiter of quality before a trunk lid is approved for shipment to the assembly line.

What is a Trunk Lid Final Checking Fixture?

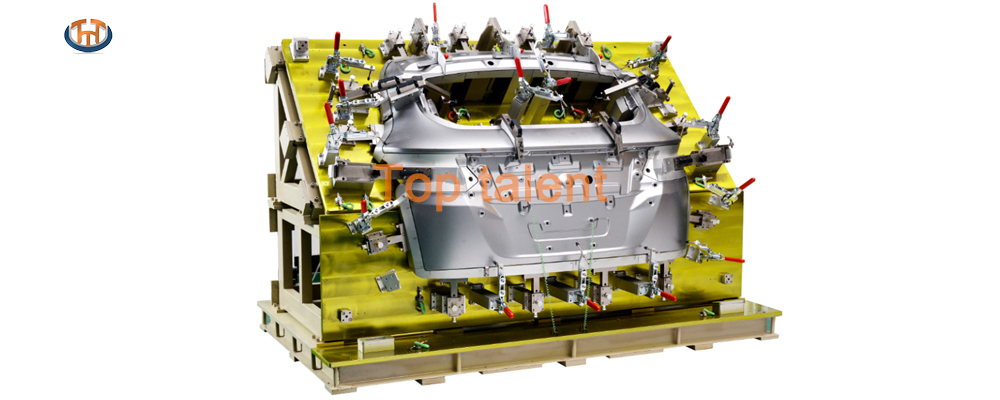

A trunk lid final checking fixture is a custom-built, precision device that replicates the exact geometry and critical interface points of the vehicle’s body structure where the trunk lid mounts and seals. Its primary function is to physically accept a newly produced trunk lid assembly and verify its dimensional accuracy, fit, and flushness against the master datum structure.

Think of it as a perfect, physical negative of the car’s rear end. It doesn’t just measure one aspect; it provides a holistic validation of the entire assembly, including the outer panel, inner frame, hinges, lock mechanism, and even emblem placements.

Key Functions and Components: More Than Just a Gauge

A well-designed checking fixture is a symphony of engineering, incorporating several key components:

Master Datum System: The “MCS” (Master Coordinate System) of the fixture. This three-plane system (typically pins and pads) positions the trunk lid in its exact nominal location, just as it would sit on the car.

Surface Verification Plates: These contour gauges, often made of transparent polycarbonate or aluminum, check the flushness and gap of the trunk lid’s outer perimeter against the adjacent quarter panels and rear fascia.

Hole and Bracket Locators: Custom mandrels and probes verify the precise location and diameter of holes for hinges, locks, wiring harnesses, and badges.

Sealing Surface Verification: A critical check that ensures the trunk lid’s inner flange provides a perfect, continuous surface for the weatherstrip seal, preventing water and wind noise leaks.

Measurement Instrument Mounting: The fixture is often equipped with dedicated nests for Coordinate Measuring Machine (CMM) arms or laser scanner mounts for collecting quantifiable data.

The Business Impact: Why This Fixture is Non-Negotiable

Investing in a high-quality final checking fixture is not an expense; it’s an insurance policy against catastrophic failures.

Preventing Costly Rejects and Rework: By catching a dimensional deviation early—a misaligned hinge point, a warped panel—manufacturers can correct the stamping or assembly process before thousands of defective parts are produced.

Ensuring Perfect Fit and Finish: Consumers judge vehicle quality by the gaps. A consistent, even gap around the trunk lid is a hallmark of a well-built car. The checking fixture is the primary tool for achieving this.

Accelerating Production Launches: During new model launches, these fixtures are vital for quickly validating production parts and signing off on tooling, getting vehicles to market faster.

Resolving Disputes: When there is a disagreement between a part supplier and the OEM, the checking fixture serves as the impartial, physical standard to determine if the part is truly within specification.

Conclusion: The Gold Standard in a Digital Age

In an era dominated by digital data, the trunk lid final checking fixture remains an essential bridge between the virtual and the physical. It provides immediate, actionable feedback that no screen can fully replicate. It is the unsung hero that ensures the satisfying, solid thud of a perfectly closing trunk lid—a small but significant detail that defines the quality of the modern automobile. For any manufacturer serious about precision and brand reputation, mastering this final check is not optional; it’s fundamental.

Post time: Oct-31-2025

.png)

.png)