Massive Selection for Rail Welding Fixture - China Top Quality Cover Assembly Bonding Tooling with jigs & welding fixtures – TTM

Massive Selection for Rail Welding Fixture - China Top Quality Cover Assembly Bonding Tooling with jigs & welding fixtures – TTM Detail:

Description

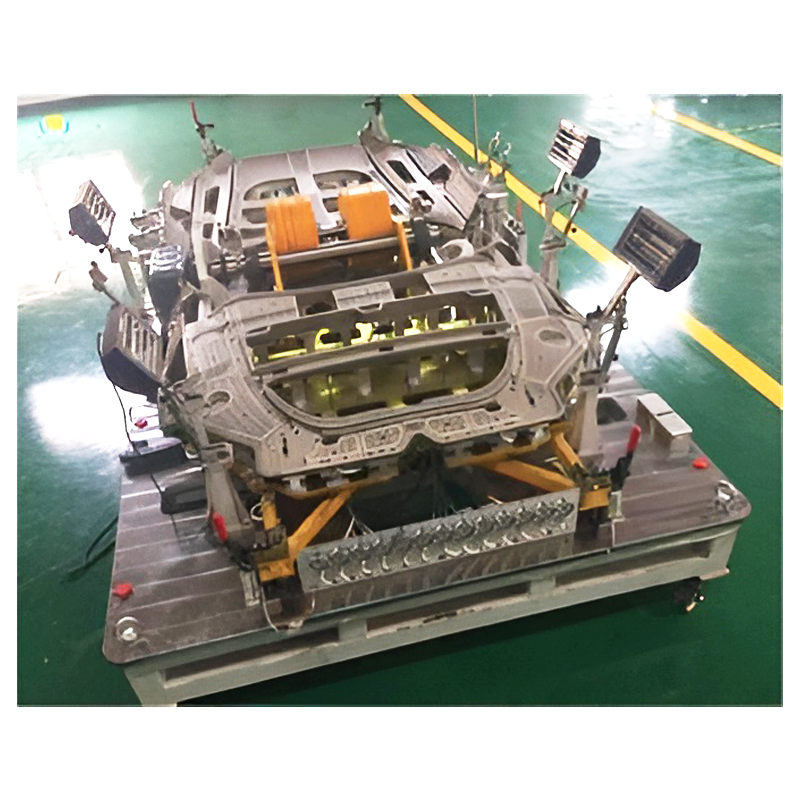

- This is a welding fixtures which will be used to Cover Assembly Bonding Tooling.

- This is a welding fixtures we made for our :China customer.

Function

For Cover Assembly Bonding Tooling quality inspection control and support to improve the automotive production line capacity rate

Application fields

Automotive industry quality control

Automotive production line production capacity improve

Specification

| Fixture Type: | Bonding Tooling |

| Project Name: | P514 |

| Size: | 1800x1300x900mm

|

| Weight:

|

130KG |

| Material:

|

Main Construction: metal

Support: metal

|

| Surface treatment:

|

Base Plate: Electroplating Chromium and Black Anodized

|

Detailed Introduction

- This is a batch of welding fixture of Cover Assembly Bonding Tooling.

- , totally in 5 sets, we made for our China customer. Begin to design, customer came our factory confirm the designing with our design team together.In the process of design, we find that several sets of designs are similar. We offered our customer one set of design first. After receiving their feedback, we well know their specific requirements and preference and then we offer them the left designs. In this way, we reduced the design reviewing times, enhancing efficiency and shortening the delivery. And provide the optimal design plan and structure for customers.

The working flow

Received the purchasing order->Design->Confirming the drawing/solutions-> Prepare the materials->CNC–>CMM–> assembling–> CMM–>Inspecting–> (3rd parts inspections if need)-> Package(with wooden)–>delivery

Manufacturing tolerance

1.The Flatness of Base Plate 0.05/1000

2.The Thickness of Base Plate ±0.05mm

3.The Location Datum ±0.02mm

4.The Surface ±0.1mm

5.The Checking Pins and Holes ±0.05mm

Process

CNC Machining(Milling/Turning), Grinding

Electroplating Chromium and Black Anodized Treatment

Design Hours(h):40h

Build Hours(h):150h

Quality Control

CMM (3D Coordinate Measuring Machine), Vms-2515G 2D Projector, HR-150 A Hardness Tester

Third Party Certification done by ShenZhen Silver Basis Testing Technology Co., Ltd , ISO17025 Certified

Lead time & Packing

45 days after 3D design approved

5 days via express: FedEx by Air

Standard Export Wooden Case

We will add fixing wooden block inside cases to make sure fixture safety in shipping. Desiccant and plastic wrap will be used to keep the checking fixture from moisture in shipping.

Product detail pictures:

Related Product Guide:

Our goal is to provide high quality products at competitive prices, and top-notch service to customers around the world. We are ISO9001, CE, and GS certified and strictly adhere to their quality specifications for Massive Selection for Rail Welding Fixture - China Top Quality Cover Assembly Bonding Tooling with jigs & welding fixtures – TTM , The product will supply to all over the world, such as: kazakhstan, Lebanon, Seychelles, Certainly, competitive price, suitable package and timely delivery will be assured as per customers' demands. We sincerely hope to build business relationship with you on the basis of mutual benefit and profit in the very near future. Warmly welcome to contact us and become our direct cooperators.

The factory has advanced equipment, experienced staffs and good management level, so product quality had assurance, this cooperation is very relaxed and happy!

1.png)

.png)

.png)