Manufacturer for Milling Parts - Special Customized BIW Checking Fixture / Main Material For Al – TTM

Manufacturer for Milling Parts - Special Customized BIW Checking Fixture / Main Material For Al – TTM Detail:

|

Base Material: |

Al |

Application: |

Stamping Parts |

|

Surface Treatment: |

Oxidation/Paint |

Processing Precision: |

0.15 |

|

Accuracy For Other Profiles: |

0.1 |

Certificate: |

ISO 9001:2008 |

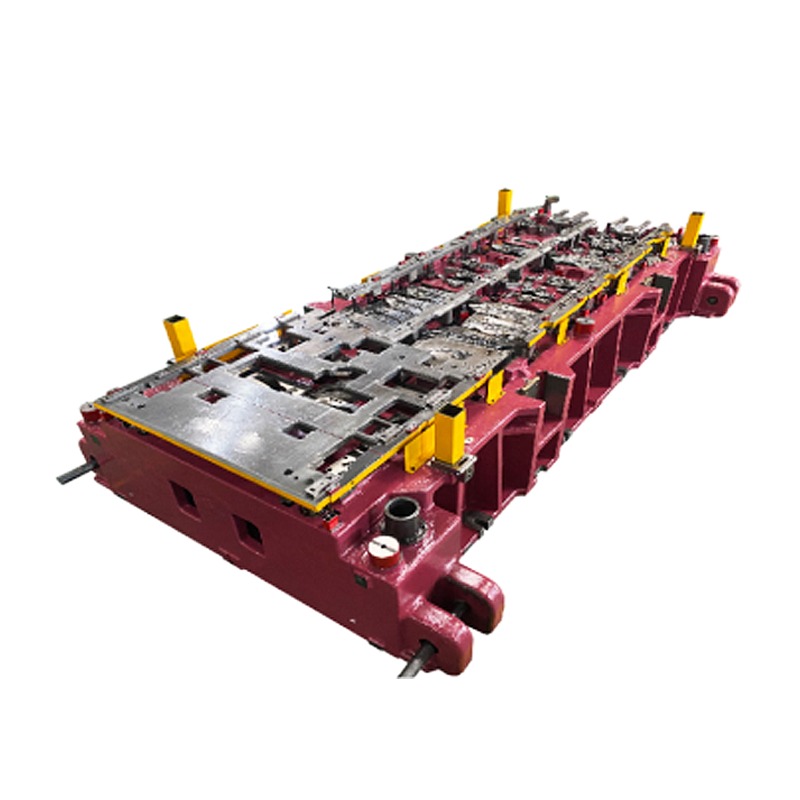

Special Customized BIW Checking Fixture / Main Material For Al

Grid reference points for determining the reference levels XY, ZX and YZ are integrated in the gauge body

using sockets as the starting basis for production and control of the location points on the specimen and

various testing details such as GG, SM, etc.

These sockets have to be located parallel to the grid so that they are available (usually vertical from top) by scanning head of the coordinate-measuring instrument. In addition to protect, the sockets have to be located in sufficient distance to the edge.

The applied jacks have to exhibit an inner diameter of 8mm. For the insertion of optical calibration help the jacks have to

be continuous or need to have a minimum depth of 15mm.

Our production detail

| Items | ||

| 1 | Base Material | Al |

| 2 | Application | Stamping Parts |

| 3 | Surface treatment | Oxidation/Paint |

| 4 | Processing Precision | 0.15 |

| 5 | Accuracy for Other Profiles | 0.1 |

| 6 | Accuracy for Datum Hole | ±0.05 |

| 7 | Certificate | ISO 9001:2008 |

| 8 | CMM certification | Yes |

| 9 | Software | Catia, UG, CAD, STP |

| 10 | Specification | 430KG |

| 11 | Packing | Wooden Box |

Manufacturing tolerance

1.The Flatness of Base Plate 0.05/1000

2.The Thickness of Base Plate ±0.03mm

3.The Location Datum ±0.02mm

4.The Surface ±0.1mm

5.The Checking Pins and Holes ±0.1mm

Process

CNC Machining(Milling/Turning), Grinding

Electroplating Chromium Treatment

Quality Control

CMM (3D Coordinate Measuring Machine), Vms-2515G 2D Projector, HR-150 A Hardness Tester

Third Party Certification done by ShenZhen Silver Basis Testing Technology Co., Ltd , ISO17025 Certified

Lead time & Packing

35 days after 3D design approved

7 days via express: FedEx

Standard Export Wooden Case

Primary Competitive Advantages

Pursuit Of Quality Excellence

Multiple Products & Services

Efficiency Consciousness-On-Time Delivery

Cost Consciousness-Innovative Design Solutions To Reduce The Cost

Timely Communication With Our Customer

Compliance With Cooperator’s Terms And Conditions

NDA(Non-disclosure Agreement)

Our purpose is that we can only succeed if our customers succeed.

Product detail pictures:

Related Product Guide:

Our growth depends on the superior equipment ,exceptional talents and continuously strengthened technology forces for Manufacturer for Milling Parts - Special Customized BIW Checking Fixture / Main Material For Al – TTM , The product will supply to all over the world, such as: Jeddah, Accra, Cannes, Our items are widely recognized and trusted by users and can meet continuously developing economic and social needs. We welcome new and old customers from all walks of life to contact us for future business relationships and achieving mutual success!

The company has a good reputation in this industry, and finally it tured out that choose them is a good choice.

.png)

.png)