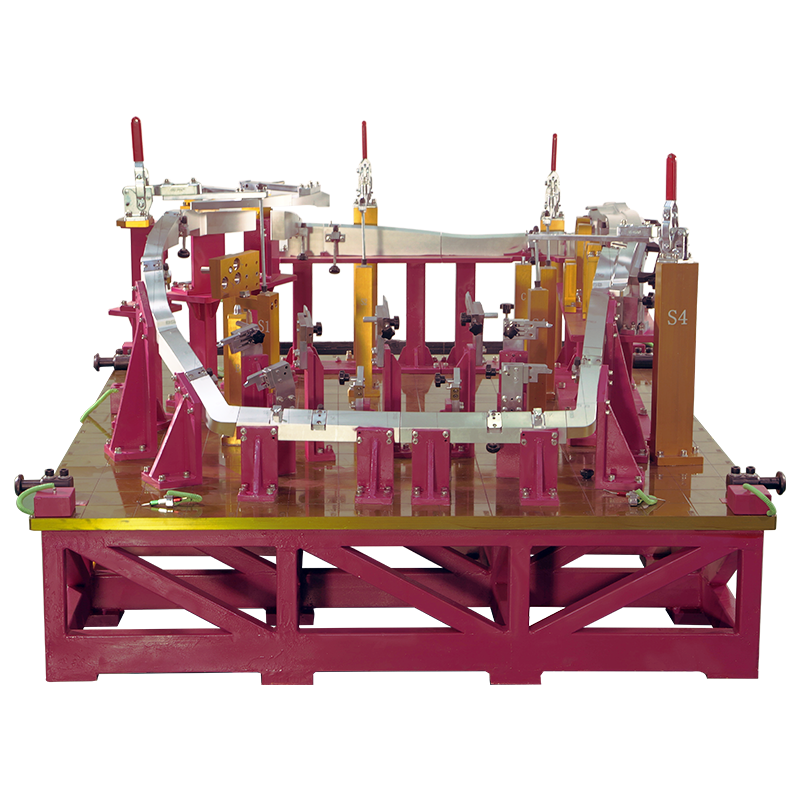

High Quality Checking Gauges - Assembly Checking Fixture for Metal Stamping Parts – TTM

High Quality Checking Gauges - Assembly Checking Fixture for Metal Stamping Parts – TTM Detail:

Function

Old version single checking fixture, it is a set of inspection tools can only be applied to a single model, detection function. A deficiency, such as a deficiency; And the degree of automation is low. The production of different models need different inspection tools, and each set of inspection tools occupies a large space area, which brings inconvenient user management and high production cost. The technical problem to be solved by the utility model is to provide an assembly checking fixture.

Application field

Automotive industry quality control.

Automotive production line production capacity improve.

Product Details

Specification

|

Fixture Type: |

Assembly CF for Metal Stamping Part |

|

Size: |

4650x850x3400 |

|

Weight: |

3550 KG |

|

Material: |

Main Construction: metal Support: metal |

Detailed Introduction

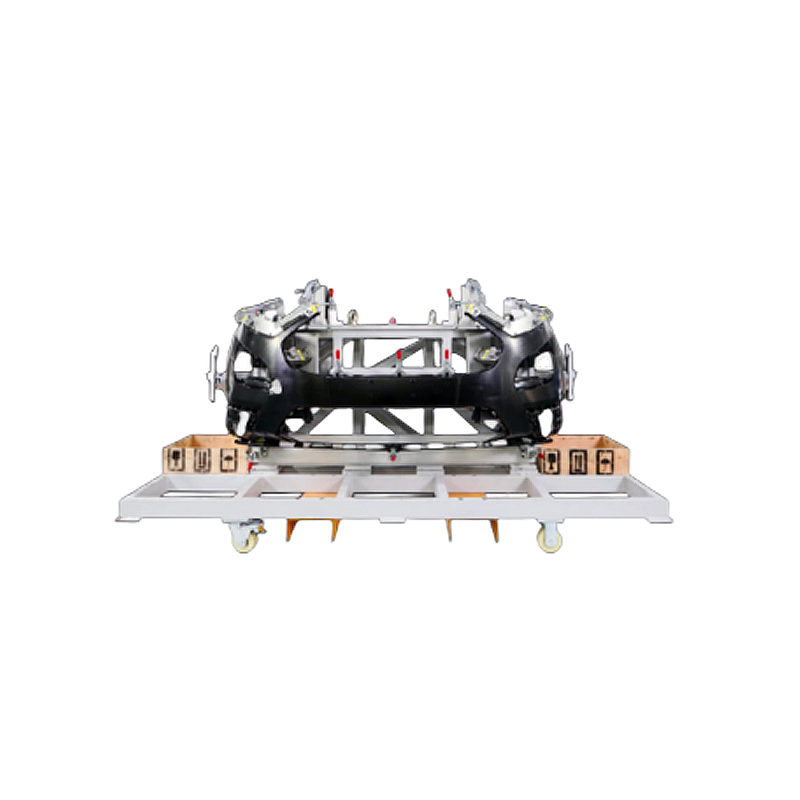

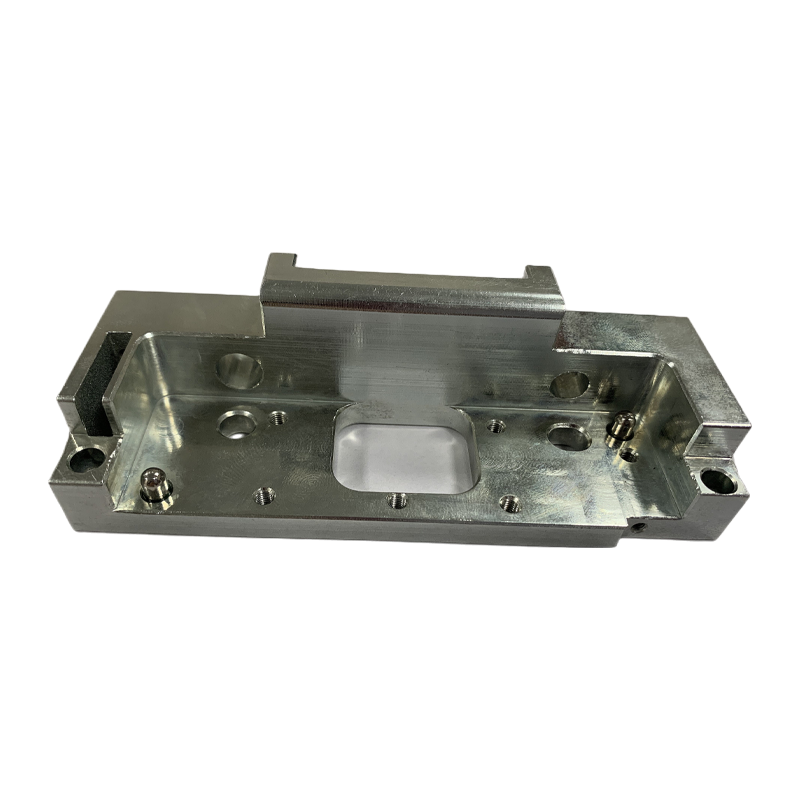

This is the vehicle function parts assembly check fixture model. The product is a large injection molded part. After the assembly of various parts and circuit boards is completed, it is put into the inspection tool for batch inspection. It is the last process before production and packaging after functional testing. Inspection tools include: 0 position plane, 3mm gap detection position, difference gauge, gap detection gauge, reference block, body coordinate system, etc

Engineering & Design

Research and Development

Design Concept&Proposal

In-house design & detail services

3D parametric solid modeling

2D Drawing Building

FEA analysis available

On-line web conference design review

Engineering Change Technical Support

Design Software: UG(Unigraphics NX)

Catia and Autodesk-Auto-CAD

Our deign team will take project responsibility system to manage all of the projects from our customers.

Project leaders with at least 10 years experience in this industry will take care of every project.

Project leader: 12 years experience, 5 people

Designer: 5 to 8 years experience, 12 people; 3 to 5 years experience, 7 people; 1 to 2 years experience, 6 people

The Working Flow

1. Received the purchasing order -——-> 2. Design -——-> 3. Confirming the drawing/solutions -——-> 4. Prepare the materials -——-> 5. CNC -——-> 6. CMM -——-> 6. Assembling -——-> 7. CMM-> 8. Inspection -——-> 9. (3rd part inspection if need) -——-> 10. (internal/customer on site) -——-> 11. Packing(wooden box) -——-> 12. Delivery

Lead time & Packing

45 days after 3D design approved

5 days via express: FedEx by Air

Standard Export Wooden Case

Product detail pictures:

Related Product Guide:

Fast and great quotations, informed advisers to help you choose the correct solution that suits all your requirements, a short creation time, responsible top quality manage and distinct providers for paying and shipping affairs for High Quality Checking Gauges - Assembly Checking Fixture for Metal Stamping Parts – TTM , The product will supply to all over the world, such as: Gabon, Roman, Accra, Please really feel free to send us your requirements and we'll respond to you asap. We have got a professional engineering group to serve for your just about every detailed needs. Cost-free samples could be sent for you personally to understand much more information. In an effort to meet your requires, please really feel free to make contact with us. You may send us emails and contact us directly. Moreover, we welcome visits to our factory from around the globe for much better recognizing of our organization. nd items. In our trade with merchants of numerous countries, we usually adhere for the principle of equality and mutual benefit. It is actually our hope to market, by joint efforts, each trade and friendship to our mutual advantage. We look forward to getting your inquiries.

We have been engaged in this industry for many years, we appreciate the work attitude and production capacity of the company, this is a reputable and professional manufacturer.

.png)

.png)