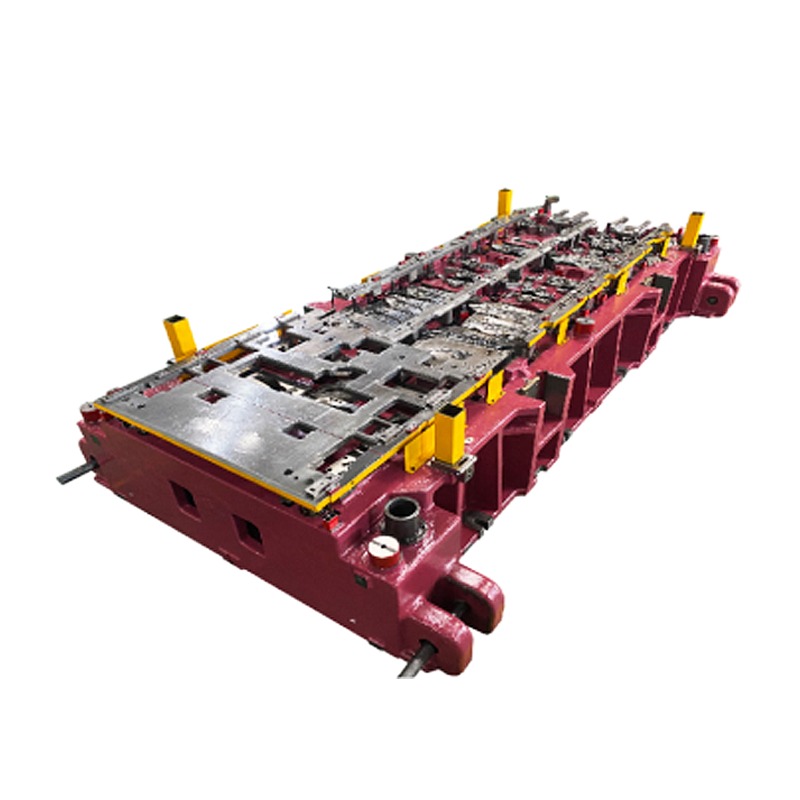

Good quality Metal Stamp - Prototype Part – TTM

Good quality Metal Stamp - Prototype Part – TTM Detail:

Function

Automotive industry for parts of car.

Automotive production line production capacity improve.

Machining Center

We can build all kinds of different size dies including Max. size as 6 meters ,we have 6 meters CNC with high precision

Our Company is aspired to use the newest and adequate Technologies, to make our customers and ourselves satisfied in every time.

Tooling try-out and adjustment

Advanced and adequate press facility,our technical team with more than 10 years of working experience in tooling industry.

800T press:Bolster size :4000*2000

1250T press:Bolster size :5500*2500

Project Management

One stop service — TTM Group have a team in each of three companies, to support customers from program start to completion.

Save time —— Effective communication— Any issues arising (stamping tool, welding fixture, checking fixture) is dealt with quickly and efficiently via video conference supported by multilingual program managers .

Cost savings —— TTM Group supports customer build requirements by providing samples and managing shipments anywhere.

Live Update —— Live online project tracking accessible to customers.

Senior talent —— Highly experienced multilingual Technical Director on site In China to facilitate design and build to a highest standards.

Project feedback —— Weekly work Completion Reports from China.

Project meeting —— Weekly Project Steering committee online meetings weekly for issues escalation, if any.

The Working Flow

This is a Prototype Part , we made for our Canada customer. Begin to design, customer came our factory confirm the designing with our design team together.In the process of design, we find that several sets of designs are similar. We offered our customer one set of design first. After receiving their feedback, we well know their specific requirements and preference and then we offer them the left designs. In this way, we reduced the design reviewing times, enhancing efficiency and shortening the delivery. And provide the optimal design plan and structure for customers.

The Working Flow

1. Received the purchasing order -——-> 2. Design -——-> 3. Confirming the drawing/solutions -——-> 4. Prepare the materials -——-> 5. CNC -——-> 6. CMM -——-> 6. Assembling -——-> 7. CMM-> 8. Inspection -——-> 9. (3rd part inspection if need) -——-> 10. (internal/customer on site) -——-> 11. Packing(wooden box) -——-> 12. Delivery

Product detail pictures:

Related Product Guide:

Our pursuit and enterprise aim would be to "Always fulfill our buyer requirements". We carry on to acquire and layout excellent quality items for the two our old and new clients and realize a win-win prospect for our shoppers in addition as us for Good quality Metal Stamp - Prototype Part – TTM , The product will supply to all over the world, such as: Swiss, Georgia, Munich, Our business activities and processes are engineered to make sure our customers have access to widest range of products with the shortest supply time lines. This achievement is made possible by our highly skilled and experienced team. We look for people who want to grow with us around the globe and stand out from the crowd. We now have people who embrace tomorrow, have vision, love stretching their minds and going far beyond what they thought was achievable.

The sales manager has a good English level and skilled professional knowledge, we have a good communication. He is a warm and cheerful man, we have a pleasant cooperation and we became very good friends in private.

.png)

.png)