Factory wholesale Welding Fixtures & Jigs - High Precision Assembly / Welding Jig Fixture 460kg With 0.15 Processing Precision – TTM

Factory wholesale Welding Fixtures & Jigs - High Precision Assembly / Welding Jig Fixture 460kg With 0.15 Processing Precision – TTM Detail:

|

Base Frame: |

Steel |

Base Material: |

Al |

|

Body Material: |

Steel |

Template Material: |

Al |

|

Weight: |

460KG |

Size: |

1200*900*860mm |

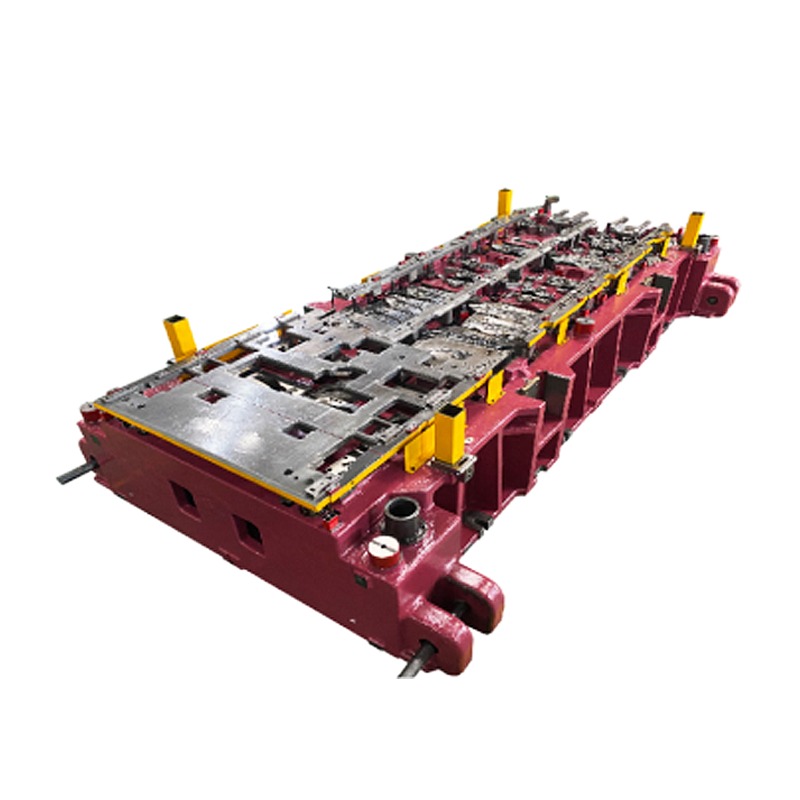

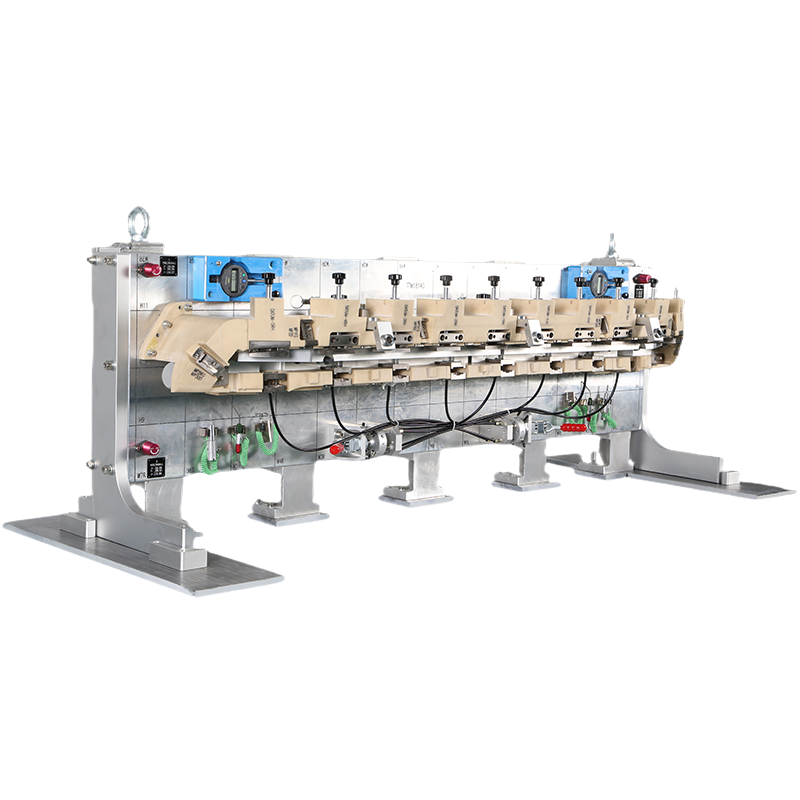

Special Customized Automotive Part Welding & Assembly Fixtures

This Welding Jigs we made for our Pakistan customer DE. These are two Welding Jigs which will be used to fix and weld cowls(small and large). Welding jigs will fix three separate parts in designated position, which will make sure welding can be done successfully.

In the design stage, our designers had on-site communication with our customer. We finished the design reviewing in only three days and got the approval for welding jigs manufacturing. Our Italian technical expert took part in the whole design reviewing and welding jigs commission and inspection.

The ergonomic design of these welding jigs minimizes the work needed to complete a task, enhancing efficiency and welding quality.

Welding Jigs will be shipped with requisite operation instruction and CMM inspection report.

Dust covers will be specially made for Welding Jigs protection. In the buy-off stage, we also made double inspection with CMM per our customer requirement.

Our production detail

| Items | ||

| 1 | Base Material | Al |

| 2 | Application | Stamping Parts |

| 3 | Surface treatment | Oxidation/Paint |

| 4 | Processing Precision | 0.15 |

| 5 | Accuracy for Other Profiles | 0.1 |

| 6 | Accuracy for Datum Hole | ±0.05 |

| 7 | Certificate | ISO 9001:2008 |

| 8 | CMM certification | Yes |

| 9 | Software | Catia, UG, CAD, STP |

| 10 | Specification | 1200*900*860mm |

| 11 | Packing | Wooden Box |

Manufacturing tolerance

1.The Location Datum ±0.05mm

2.The Surface ±0.15mm

3.The Checking Pins and Holes ±0.1mm

Process

CNC Machining(Milling/Turning), Grinding

Black Anodized Treatment

Design Hours(h): 60h

Quality Control

CMM (3D Coordinate Measuring Machine), HR-150 A Hardness Tester

Lead time & Packing

2 months after 3D design approved

15 days via sea: HMM

Standard Export Wooden Case

Quality Policy

Legal Compliance

Customer First

Total Quality Control

System Operation

Continuous Improvement

More

We’re dedicated to providing our customers with high quality, practical, and cost-effective solutions that serve a variety of needs in the areas of checking fixtures, welding fixtures and jigs! We will work closely with customers to define their needs and assess critical design factors such as functionality, productivity requirements.

Product detail pictures:

Related Product Guide:

abide by the contract", conforms to the market requirement, joins in the market competition by its high quality as well as provides more comprehensive and excellent service for clients to let them become big winner. The pursue of the company, is the clients' satisfaction for Factory wholesale Welding Fixtures & Jigs - High Precision Assembly / Welding Jig Fixture 460kg With 0.15 Processing Precision – TTM , The product will supply to all over the world, such as: Poland, Turkmenistan, Casablanca, We follow superior mechanism to process these products that ensure optimum durability and reliability of the products. We follow latest effective washing and straightening processes that allow us to offer unmatched quality of products for our clients. We continually strive for perfection and all our efforts are directed towards attaining complete client satisfaction.

Company director has very rich management experience and strict attitude, sales staff are warm and cheerful, technical staff are professional and responsible,so we have no worry about product,a nice manufacturer.

.png)

.png)