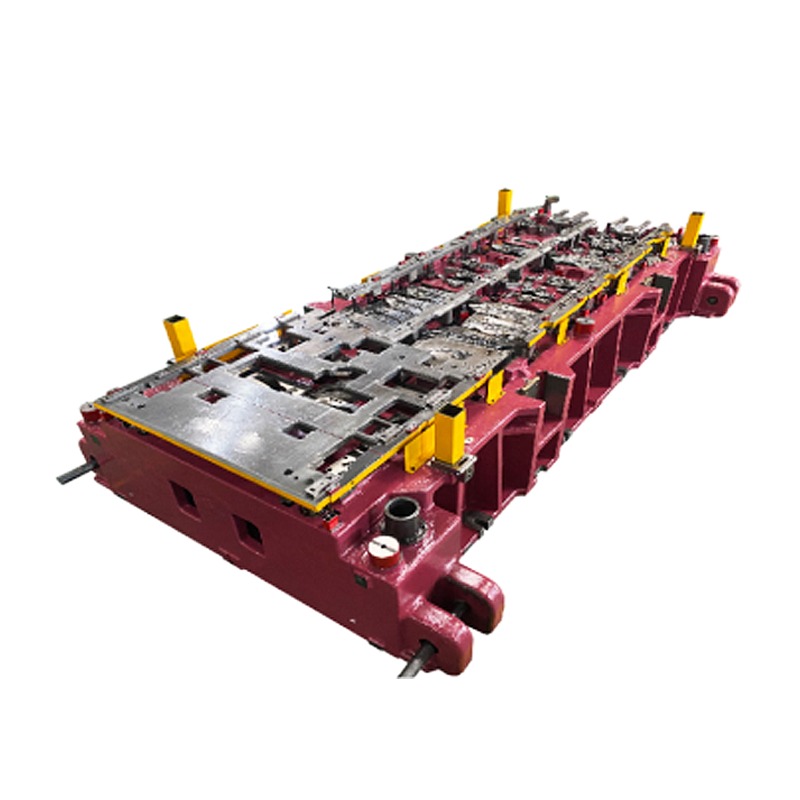

factory Outlets for Fender Welding Fixture - AB Ring Arc Welding Fixtures/jigs- BX755(19018) – TTM

factory Outlets for Fender Welding Fixture - AB Ring Arc Welding Fixtures/jigs- BX755(19018) – TTM Detail:

Function

For AB Ring quality inspection control and support to improve the automotive production line capacity rate.

Specification

|

Fixture Type: |

Arc Welding |

|

Size: |

1800x1300x900mm |

|

Weight: |

115KG |

Product Details

Detailed Introduction

This is a batch of welding fixture of AB Ring , totally in 15 sets, we made for our Canada customer. Welding production line variety, small batch and short cycle are the main characteristics of modern machinery manufacturing industry. The appearance of this feature promotes the creation of the concept of flexible fixture and the development of technology. As the cycle of product renewal is getting shorter and shorter, how to quickly switch from old models to new models and shorten the project cycle is the research direction of each gems.

Welding fixture mainly includes fixture bottom plate, clamp specific, auxiliary mechanism, control system several parts. The bottom plate is the chassis of fixture components, automatic welding gun, lifter and other fixture components. It is the basic component of welding fixture, and its accuracy directly affects the accuracy of positioning mechanism.Circular seam automatic welding machine is a kind of universal automatic welding equipment that can complete all kinds of circular and annular welds. Can be used for carbon steel, low alloy steel, stainless steel, aluminum and its alloy and other materials of high quality welding, and can choose argon arc welding (wire or not wire), melting electrode gas welding, plasma welding and other welding power to form a ring seam automatic welding system.It can be widely used in the welding of hydraulic cylinder, automobile direction frame, drive shaft, gas storage cylinder, chemical and medical containers, liquefied gas tanks, fire fighting equipment, rollers and liquid storage cylinder for mining and production lines, etc.

The Working Flow

1. Received the purchasing order -——-> 2. Design -——-> 3. Confirming the drawing/solutions -——-> 4. Prepare the materials -——-> 5. CNC -——-> 6. CMM -——-> 6. Assembling -——-> 7. CMM-> 8. Inspection -——-> 9. (3rd part inspection if need) -——-> 10. (internal/customer on site) -——-> 11. Packing(wooden box) -——-> 12. Delivery

Lead time & Packing

30 days after 3D design approved

5 days via express: FedEx by Air

Standard Export Wooden Case

Product detail pictures:

Related Product Guide:

The client satisfaction is our primary concentrate on. We uphold a consistent level of professionalism, top quality, credibility and service for factory Outlets for Fender Welding Fixture - AB Ring Arc Welding Fixtures/jigs- BX755(19018) – TTM , The product will supply to all over the world, such as: Denver, Hyderabad, Belgium, Today, We are with great passion and sincerity to further fulfill our global customers' needs with good quality and design innovation. We fully welcome customers from all over the world to establish stable and mutually beneficial business relationships, to have a bright future together.

As an international trading company, we have numerous partners, but about your company, I just want to say, you are really good, wide range, good quality, reasonable prices, warm and thoughtful service, advanced technology and equipment and workers have professional training, feedback and product update is timely, in short, this is a very pleasant cooperation, and we look forward to the next cooperation!

.png)

.png)