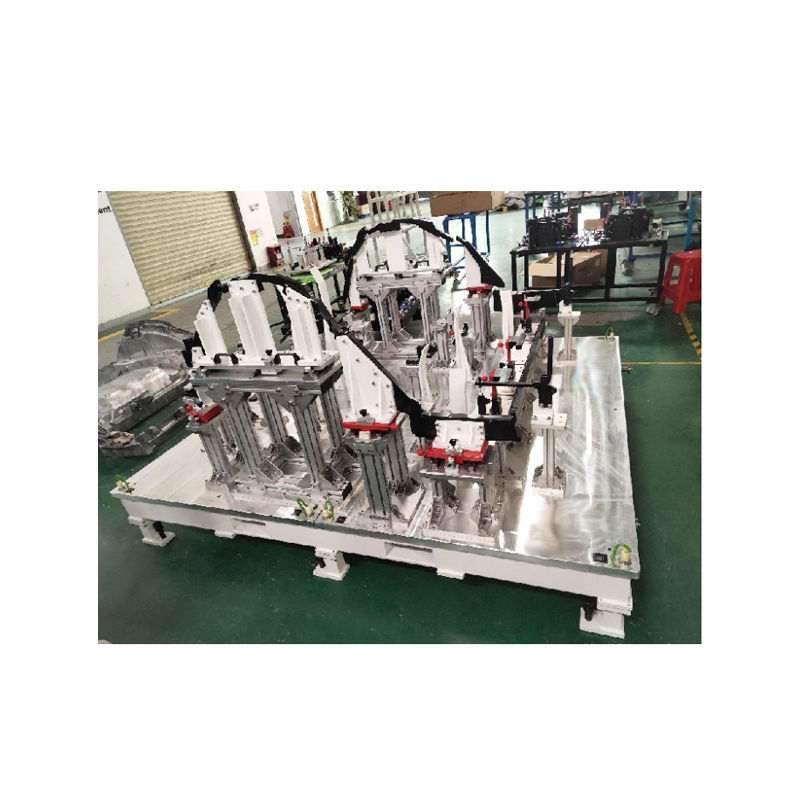

factory Outlets for Composite Lay-Up Fixtures - Rear Underbody One Piece Casting Assembly Checking Fixture – TTM

factory Outlets for Composite Lay-Up Fixtures - Rear Underbody One Piece Casting Assembly Checking Fixture – TTM Detail:

Function

For Rear Underbody One Piece Casting quality inspection control and support to improve the automotive production line capacity rate.

Specification

|

Fixture Type: |

Body Assembly Check Fixtures |

|

Size: |

2350*980*1250 |

|

Weight: |

115KG |

Detailed Introduction

Monolithic giant die casting machine not only serves for manufacturing efficiency, for the vehicle itself, because it reduces the work of stamping and welding, so it can fundamentally solve the problem of abnormal sound of the body; For safety, the integrated molding process will also bring a highly integrated modular design, is bound to crash when the safety of the body will be greatly improved.

Technician has many design considerations to deal with sudden crash safety. In the design of Model Y body structure, eight collision situations, such as forward collision, side collision and roll, are considered. Tesla can effectively conduct and consume the impact force of the collision through the ingenious body structure design, front and rear anti-collision steel beams, energy absorption boxes and other devices to protect the safety of the occupants in an all-round way.

The Model Y body adopts a steel-aluminum hybrid body frame, and the key parts are reinforced with high-strength boron steel, which can withstand larger impact forces. The integrated thermometer inner and outer door rings (boron steel), front roof beams (boron steel), and rear roof beams (high-strength steel) form a ring-enclosed structure that provides strong support for the Model Y body. The innovative structural design of laying the battery pack flat on the bottom of the car also greatly improved the overall structural strength of the Model Y, reducing the risk of rollover and side impact invasion.

The Working Flow

1. Received the purchasing order -——-> 2. Design -——-> 3. Confirming the drawing/solutions -——-> 4. Prepare the materials -——-> 5. CNC -——-> 6. CMM -——-> 6. Assembling -——-> 7. CMM-> 8. Inspection -——-> 9. (3rd part inspection if need) -——-> 10. (internal/customer on site) -——-> 11. Packing(wooden box) -——-> 12. Delivery

Manufacturing tolerance

1. The Flatness of Base Plate 0.05/1000

2. The Thickness of Base Plate ±0.05mm

3. The Location Datum ±0.02mm

4. The Surface ±0.1mm

5. The Checking Pins and Holes ±0.05mm

Product detail pictures:

Related Product Guide:

It adheres for the tenet "Honest, industrious, enterprising, innovative" to develop new products and solutions continuously. It regards shoppers, success as its individual success. Let us produce prosperous future hand in hand for factory Outlets for Composite Lay-Up Fixtures - Rear Underbody One Piece Casting Assembly Checking Fixture – TTM , The product will supply to all over the world, such as: Jordan, venezuela, French, They're durable modeling and promoting well all over the world. Under no circumstances disappearing key functions in a brief time, it's a should for you personally of fantastic quality. Guided by the principle of Prudence, Efficiency, Union and Innovation. the business make an awesome efforts to expand its international trade, raise its enterprise. rofit and improve its export scale. We are confident that we'll have a vibrant prospect and to be distributed all over the world in the years to come.

The sales person is professional and responsible, warm and polite, we had a pleasant conversation and no language barriers on communication.

1.png)

.png)

.png)