Bottom price Robotic Mig Welding Lines - Jigs Of Automotive Part / Electric Systems Control To Matching Robot Welding System – TTM

Bottom price Robotic Mig Welding Lines - Jigs Of Automotive Part / Electric Systems Control To Matching Robot Welding System – TTM Detail:

|

Welding Frame: |

Steel |

Base: |

Steel |

|

Supporter: |

Steel |

System: |

Electric |

|

Color: |

Printing |

Design Software: |

UG |

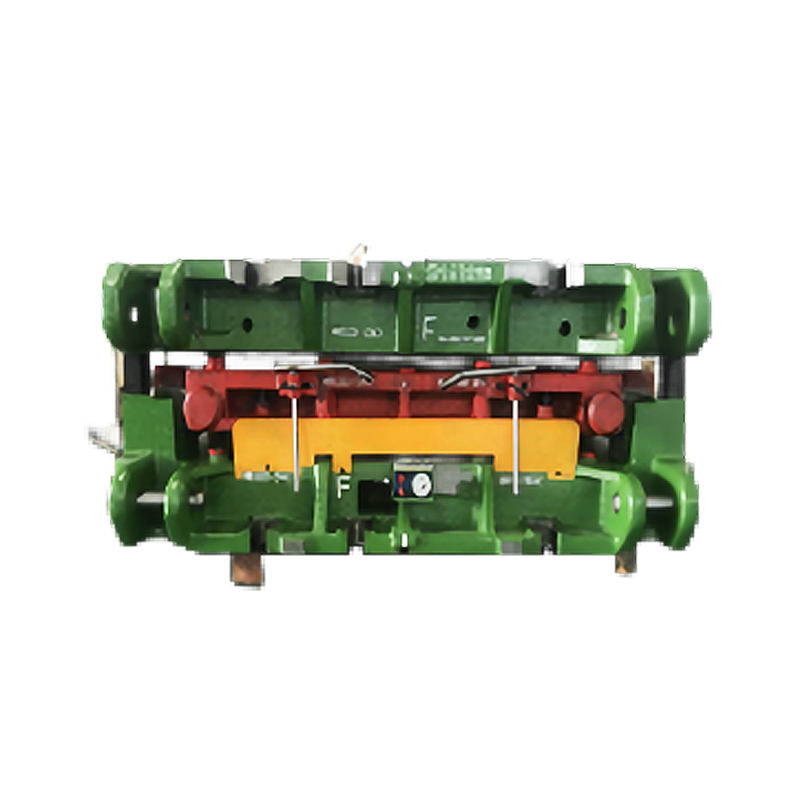

Jigs of Automotive Part / Electric Systems Control to Matching Robot Welding System

Product Description

This jigs has exquisite structure design , high repeating accuracy and easy switching. Pushing the jig inward directily and making it reach a flat plane(the jig fixed in the Z direction), and then plugging the positioning pin behind(the way can also be changed to other electric positioning device) , switching is completed.

And we have detailed English Operating instruction with clear guidance for gauge using will be offed to our customer.

Our customer can also download these instructions form our website at any time.

Specification

The Average Gauge Size : 1900*1300*1500

The Average Weight:1250KG

Material

Base Plate : Steel

Color

Base Plate and Body: Printing

The Steel and Aluminum Parts: Original Color of Metal

Our production detail

| Items | ||

| 1 | Base Material | Al |

| 2 | Application | Carbon Fiber Parts |

| 3 | Surface treatment | Oxidation/Paint |

| 4 | Processing Precision | 0.15 |

| 5 | Accuracy for Other Profiles | 0.1 |

| 6 | Accuracy for Datum Hole | ±0.05 |

| 7 | Certificate | ISO 9001:2008 |

| 8 | CMM certification | Yes |

| 9 | Software | Catia, UG, CAD, STP |

| 10 | Specification | 1900*1300*1500 |

| 11 | Packing | Wooden Box |

Manufacturing tolerance

1.The Flatness of Base Plate 0.1/1000

2.The Thickness of Base Plate ±0.1mm

3.The Location Datum ±0.1mm

4.The Surface ±0.1mm

5.The Checking Pins and Holes ±0.1mm

Process

CNC Machining(Milling/Turning), Grinding

Electroplating Chromium Treatment

Quality Control

CMM (3D Coordinate Measuring Machine), Vms-2515G 2D Projector, HR-150 A Hardness Tester

Lead time & Packing

35 days after 3D design approved

7 days via express: FedEx

Standard Export Wooden Case

Primary Competitive Advantages

Pursuit Of Quality Excellence

Multiple Products & Services

Efficiency Consciousness-On-Time Delivery

Cost Consciousness-Innovative Design Solutions To Reduce The Cost

Timely Communication With Our Customer

Compliance With Cooperator’s Terms And Conditions

NDA(Non-disclosure Agreement)

Product detail pictures:

Related Product Guide:

Our enterprise since its inception, often regards solution excellent as enterprise life, continually strengthen output technology, enhance product high quality and continually strengthen organization total high-quality administration, in strict accordance using the national standard ISO 9001:2000 for Bottom price Robotic Mig Welding Lines - Jigs Of Automotive Part / Electric Systems Control To Matching Robot Welding System – TTM , The product will supply to all over the world, such as: United Kingdom, America, Estonia, At Present, our products have been exported to more than sixty countries and different regions, such as Southeast Asia, America, Africa, Eastern Europe, Russia, Canada etc. We sincerely hope to establish wide contact with all potential customers both in China and the rest part of the world.

We are a small company that has just started, but we get the company leader's attention and gave us a lot of help. Hope we can make progress together!

.png)

.png)