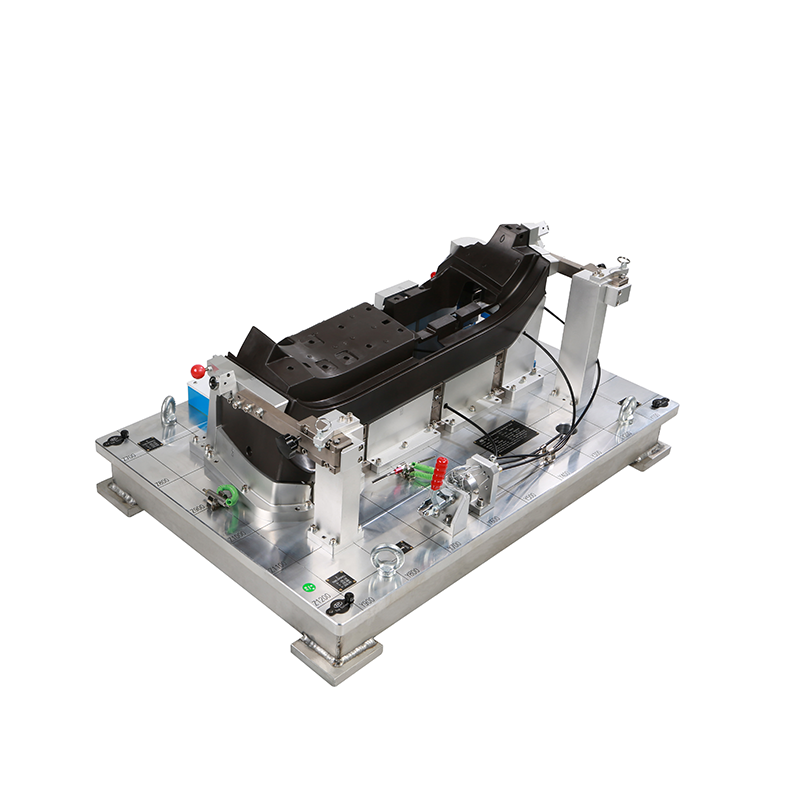

8 Year Exporter Stamping Parts Checking Fixture - New Product Single Plastic Part Checking Fixtures product – TTM

8 Year Exporter Stamping Parts Checking Fixture - New Product Single Plastic Part Checking Fixtures product – TTM Detail:

Function

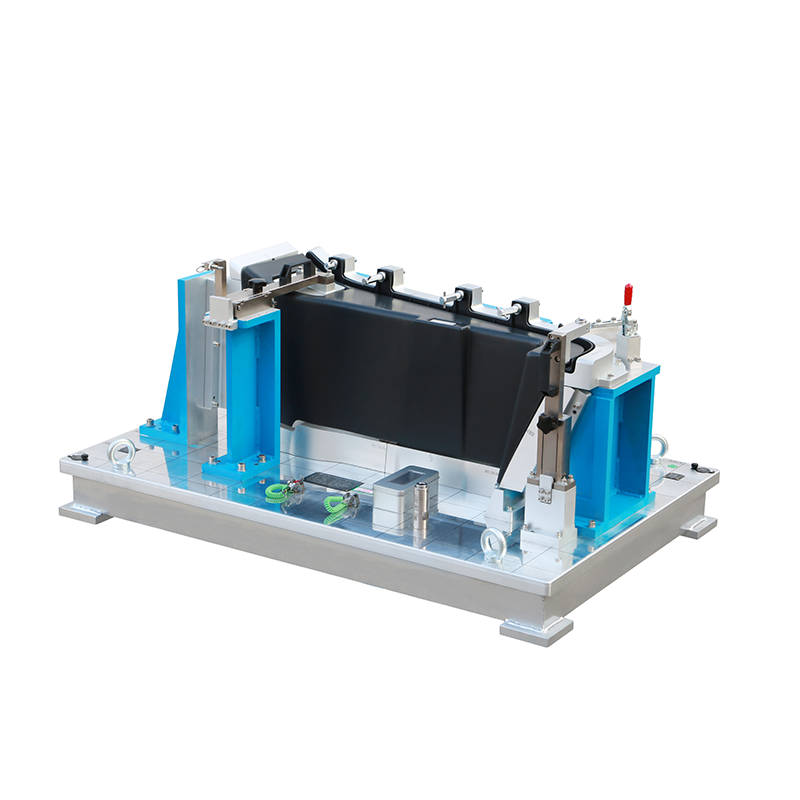

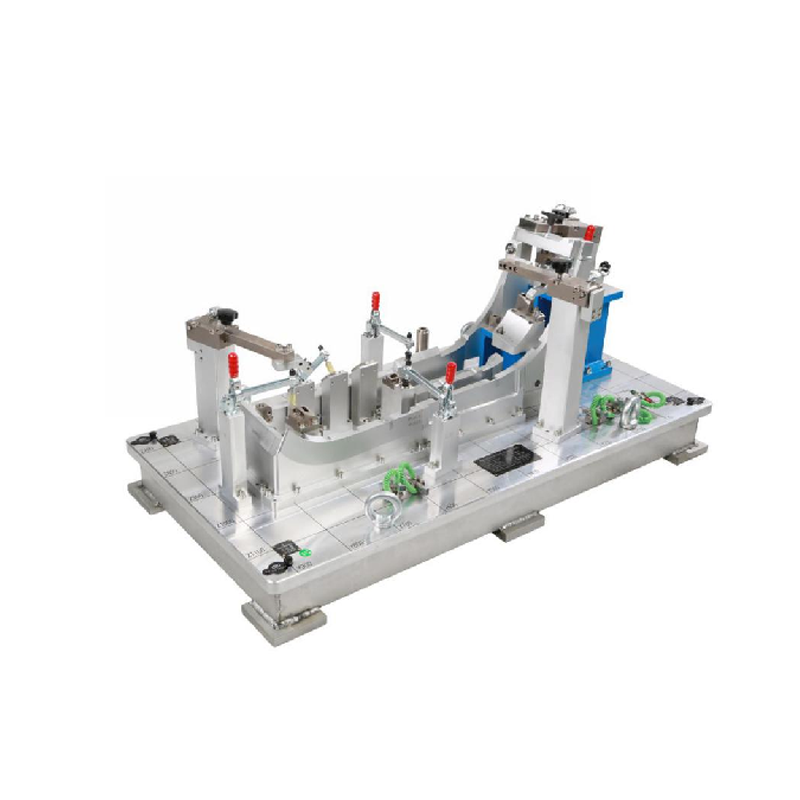

For Front Bumper quality inspection control and support to improve the automotive production line capacity rate

Specification

|

Fixture Type: |

ASSY Checking Fixture |

|

Size: |

560*340*350 |

|

Weight: |

126KG |

Product Details

Use And Maintenance

As a special inspection tool, the inspection tool shall be operated by special personnel. Under the specified environment, such as temperature and humidity, the inspection parts shall be operated according to the specified steps in the operation manual of the inspection tool. The inspection tool needs regular maintenance, pay attention to the lubrication of the positioning hole pin, the rust prevention of the inner and outer functional surface, and the dust removal of the body bottom plate. Similar to measuring instruments, inspection instruments need to be checked periodically (such as every year) by the measuring department and marked well.

It is necessary to avoid the idea of attaching importance only to the parts but not to the fixture, and to correct the idea of attaching importance only to the manufacture of the fixture but not to its use. If ever spend resources and manpower equipped with a fixture, but later it is “deep lock in the best” or dusty corner, no one will use or improper use, or someone can correct operation but it is not in the daily production application, there is no correct play the role of fixture measurement and evaluation part, has violated the development submit good original intention, a pity don’t accord with the requirement of quality process system. The tester to test and evaluate the parts, make relevant records every time, and control the product quality carefully.

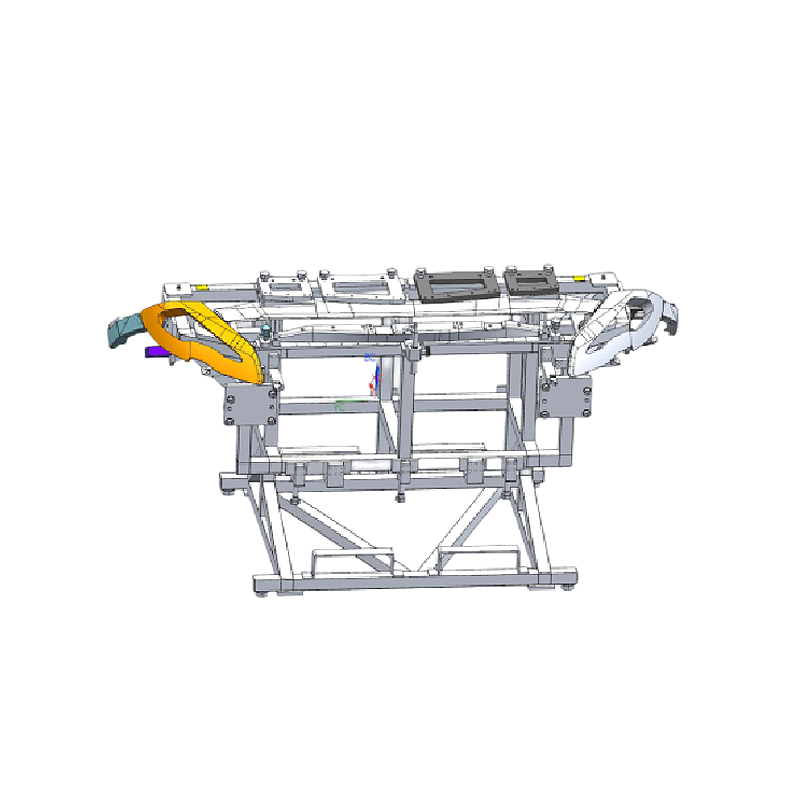

The Working Flow

1. Received the purchasing order -——-> 2. Design -——-> 3. Confirming the drawing/solutions -——-> 4. Prepare the materials -——-> 5. CNC -——-> 6. CMM -——-> 6. Assembling -——-> 7. CMM-> 8. Inspection -——-> 9. (3rd part inspection if need) -——-> 10. (internal/customer on site) -——-> 11. Packing(wooden box) -——-> 12. Delivery

Geographical Advantages

Convenient location:

No.1,YanHe Road, JiaoShe, DongKeng Town, DongGuan, GuangDong 523443, P.R. China

1.5 hours to GuangZhou International Airport

2 hours to HongKong International Airport

1 hour to ShenZhen International Airport

Geographical advantages:

1. It is close to Hong Kong and Shenzhen, saving the cost of transportation

2. It is located in key high-tech production industrial zone in southern China, the supporting facilities around are complete.

Lead time & Packing

30 days after 3D design approved

5 days via express: FedEx by Air

Standard Export Wooden Case

We will add fixing wooden block inside cases to make sure fixture safety in shipping. Desiccant and plastic wrap will be used to keep the checking fixture from moisture in shipping.

Product detail pictures:

Related Product Guide:

Our advancement depends on the superior gear ,superb talents and consistently strengthened technology forces for 8 Year Exporter Stamping Parts Checking Fixture - New Product Single Plastic Part Checking Fixtures product – TTM , The product will supply to all over the world, such as: Jordan, Cyprus, Greenland, They're durable modeling and promoting well all over the world. Under no circumstances disappearing key functions in a brief time, it's a must for yourself personally of fantastic quality. Guided by the principle of Prudence, Efficiency, Union and Innovation. the business make an awesome efforts to expand its international trade, raise its enterprise. rofit and improve its export scale. We have been confident that we will have a vibrant prospect and to be distributed all over the world in the years to come.

Products and services are very good, our leader is very satisfied with this procurement, it is better than we expected,

.png)

.png)